In short, PTFE O-rings are best suited for specialized sealing applications where standard rubber O-rings would fail due to aggressive chemicals, extreme temperatures, or the need for very low friction. They excel in static or slow-moving systems found in industries like chemical processing, pharmaceuticals, and oil and gas.

The decision to use a PTFE O-ring is not about general-purpose sealing; it's about solving a specific problem. You choose PTFE when the operational environment is too hostile for conventional elastomers, making its unique properties of chemical inertness and thermal stability non-negotiable.

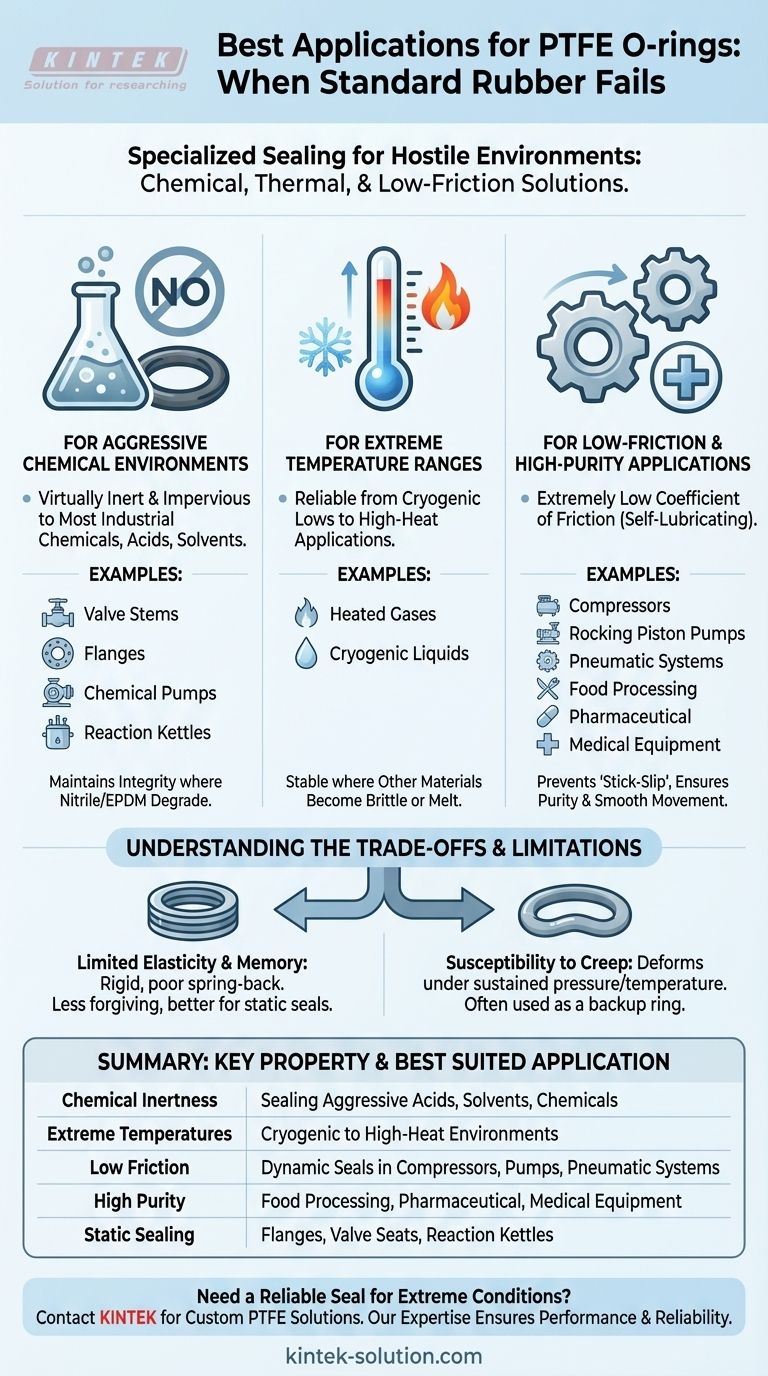

When to Choose PTFE: Core Scenarios

PTFE (Polytetrafluoroethylene) is not a direct replacement for a standard rubber O-ring. Its material properties make it a specialist component for challenging conditions.

For Aggressive Chemical Environments

PTFE is virtually inert and impervious to most industrial chemicals, acids, and solvents. This makes it the default choice in chemically aggressive systems.

Other materials, like Nitrile or EPDM, would quickly degrade when exposed to such media. PTFE maintains its integrity, ensuring a reliable seal.

This property makes it ideal for use in valve stems, flanges, chemical pumps, and reaction kettles where the media would destroy a standard elastomer.

For Extreme Temperature Ranges

PTFE performs reliably across an exceptionally wide temperature spectrum, from cryogenic lows to high-heat applications.

It remains stable and functional in environments where other materials would become brittle or melt, making it suitable for systems handling heated gases or cryogenic liquids.

For Low-Friction and High-Purity Applications

PTFE has an extremely low coefficient of friction, meaning it is very slippery. This self-lubricating property is critical in dynamic applications where parts must move smoothly.

It prevents the "stick-slip" phenomenon common with rubber seals, making it perfect for compressors, rocking piston pumps, and pneumatic systems.

Its inherent purity and resistance to contamination also make it a primary choice for food processing, pharmaceutical, and medical equipment.

Understanding the Trade-offs and Limitations

While powerful, PTFE is not without its drawbacks. Understanding these limitations is critical to using it correctly and avoiding seal failure.

Limited Elasticity and Memory

Unlike rubber, PTFE is a rigid plastic. It has very poor elastic memory, meaning it does not spring back to its original shape after being compressed.

This makes it less forgiving of surface imperfections and less suitable for applications requiring frequent assembly and disassembly. It is a key reason why PTFE is often favored for static seals.

Susceptibility to Creep (Cold Flow)

Under sustained pressure and temperature, solid PTFE can slowly deform permanently, a phenomenon known as creep or cold flow.

This limits its effectiveness as a standalone seal in high-pressure applications. In such cases, it is often used as a backup ring to support a primary elastomer O-ring or as part of an energized seal design.

Installation Challenges

The rigidity of PTFE can make installation more difficult than with a flexible rubber O-ring. Care must be taken to avoid scratching or damaging the seal during assembly.

Making the Right Choice for Your Goal

Selecting the correct seal requires matching the material to the specific demands of the application.

- If your primary focus is sealing against aggressive chemicals or extreme temperatures: PTFE is an excellent first choice, especially for static applications like flanges and valve seats.

- If your primary focus is a low-friction dynamic seal: PTFE is a strong contender for slow-moving or reciprocating parts, but you must account for its rigidity and potential for wear.

- If your primary focus is a general-purpose, high-pressure dynamic seal: A pure PTFE O-ring is likely unsuitable due to creep and poor elasticity; consider an elastomer or an energized seal instead.

By understanding PTFE's unique profile of strengths and limitations, you can deploy it precisely where it delivers unparalleled performance.

Summary Table:

| Key Property | Best Suited Application |

|---|---|

| Chemical Inertness | Sealing aggressive acids, solvents, and chemicals |

| Extreme Temperatures | Cryogenic to high-heat environments |

| Low Friction | Dynamic seals in compressors, pumps, and pneumatic systems |

| High Purity | Food processing, pharmaceutical, and medical equipment |

| Static Sealing | Flanges, valve seats, and reaction kettles |

Need a reliable seal for extreme conditions?

PTFE O-rings from KINTEK are engineered to perform where standard elastomers fail. We specialize in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Whether you require prototypes or high-volume production, our expertise in custom fabrication ensures you get a sealing solution tailored to your specific chemical, thermal, and performance requirements.

Contact KINTEK today to discuss your application and get a quote for a PTFE sealing solution that guarantees performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support