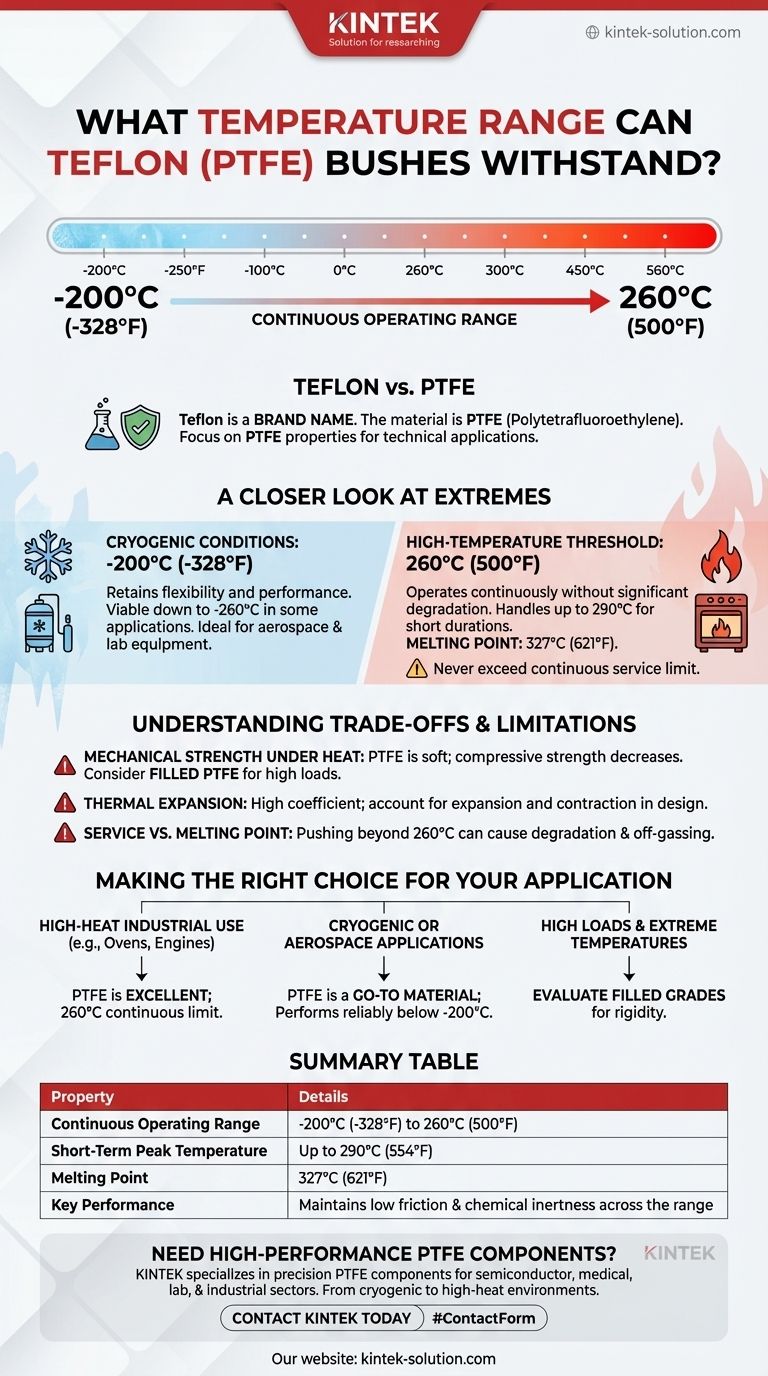

In short, Teflon (PTFE) bushes can withstand a remarkably wide temperature range, operating continuously from as low as -200°C (-328°F) up to a maximum of 260°C (500°F). This exceptional thermal stability allows them to maintain their structural integrity and performance characteristics in both cryogenic and high-heat industrial environments.

The key takeaway is not just the specific temperature range, but Teflon's ability to maintain its defining properties—such as low friction and chemical inertness—consistently across these extremes, making it a uniquely reliable material for demanding applications.

First, A Critical Clarification: Teflon vs. PTFE

The Material Behind the Name

It's important to understand that "Teflon" is a brand name for a polymer called Polytetrafluoroethylene, or PTFE.

While Teflon is the most recognized name, the properties we are discussing belong to the PTFE material itself. This distinction is crucial when sourcing components for technical applications.

A Closer Look at the Temperature Extremes

The wide operating range of PTFE is one of its most significant engineering advantages. It doesn't just survive at these temperatures; it continues to perform its function effectively.

The High-Temperature Threshold: 260°C (500°F)

PTFE can operate continuously at 260°C without significant degradation. For short durations, it can even handle temperatures up to 290°C.

This is well below its actual melting point of 327°C (621°F). The service temperature limit is set to ensure the material retains its mechanical strength, low-friction surface, and structural stability over long periods.

Performance in Cryogenic Conditions: -200°C (-328°F)

At the other end of the spectrum, PTFE remains highly functional. Unlike many plastics that become extremely brittle and fail at low temperatures, PTFE retains a useful degree of flexibility.

Some data shows it remains viable in certain applications down to -260°C (-436°F), making it a trusted choice for aerospace and laboratory equipment that operates in deep-cold environments.

Understanding the Trade-offs and Limitations

While PTFE's thermal stability is impressive, a complete technical assessment requires understanding its limitations.

Mechanical Strength Under Heat

PTFE is a relatively soft material. As temperatures rise toward the upper service limit, its compressive strength and wear resistance decrease. For applications involving high mechanical loads at high temperatures, a filled grade of PTFE (e.g., glass-filled or carbon-filled) is often a better choice.

Thermal Expansion is a Factor

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it will expand and contract significantly with temperature changes. Engineers must account for this during the design phase to ensure proper clearances are maintained throughout the operational cycle.

Service Temperature vs. Melting Point

Never confuse the continuous service temperature with the melting point. Pushing PTFE beyond 260°C for extended periods can cause it to degrade and off-gas, even before it melts. Adhering to the recommended service limit is critical for both performance and safety.

Making the Right Choice for Your Application

Use these guidelines to determine if PTFE is the correct material for your specific needs.

- If your primary focus is high-heat industrial use (e.g., ovens, engines): PTFE is an excellent choice, as its 260°C continuous limit provides a reliable operational window for most machinery.

- If your primary focus is cryogenic or aerospace applications: PTFE's proven ability to perform reliably at -200°C and below makes it a go-to material where others would fail.

- If your application involves high loads and extreme temperatures: You must evaluate if standard PTFE is sufficient or if a filled, more rigid grade is necessary to prevent deformation.

By understanding both its exceptional thermal range and its core material properties, you can confidently specify PTFE for the most demanding environments.

Summary Table:

| Property | Details |

|---|---|

| Continuous Operating Range | -200°C (-328°F) to 260°C (500°F) |

| Short-Term Peak Temperature | Up to 290°C (554°F) |

| Melting Point | 327°C (621°F) |

| Key Performance | Maintains low friction & chemical inertness across the entire range |

Need high-performance PTFE components that can handle extreme temperatures?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom bushes—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume production, our expertise ensures your components deliver reliable performance from cryogenic conditions to high-heat environments.

Contact KINTEK today to discuss your specific requirements and get a custom solution!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications