For practical and reliable operation, the temperature limitation for standard PTFE ball valves is generally considered to be from -200°C (-328°F) up to +260°C (500°F). However, the most critical factor for maintaining a reliable seal is not the absolute temperature but the magnitude of the temperature swings, which should ideally remain below 180°C to compensate for the material's thermal expansion.

While PTFE boasts an impressive theoretical temperature range, its physical expansion and contraction under thermal cycling are the true limiting factors that dictate its reliable performance and sealing integrity within a valve assembly.

Understanding PTFE's Core Properties

To properly apply a PTFE ball valve, it's essential to understand the material properties that make it so effective—and where its limitations lie.

The Source of Its Strength: Chemical Inertness

PTFE is a semi-crystalline polymer renowned for its outstanding chemical resistance. It is nearly impervious to acids, alkalis, and solvents.

This inertness makes it an ideal material for the wetted surfaces of a valve, ensuring the valve itself does not corrode or contaminate the media it controls.

The Low-Friction Advantage

With a friction coefficient of approximately 0.04, PTFE is one of the most slippery materials known. This property is what provides its self-lubricating characteristic.

In a ball valve, this means the seal against the ball is achieved with minimal torque, allowing for fast, shock-free, and reliable manual or automated operation over a long service life.

The Critical Factor: Temperature and Physical Change

A material's datasheet can be misleading if not viewed in the context of a dynamic mechanical assembly like a valve. The true limits are defined by how the material behaves under operational stress.

The Upper Service Limit (260°C / 500°F)

PTFE's melting point is a high 327°C (620°F). However, this is the point of material failure, not a safe operating temperature.

The accepted maximum continuous service temperature is 260°C (500°F). Pushing beyond this limit risks deformation and a loss of sealing capability long before the material actually melts.

The Lower Service Limit (-200°C / -328°F)

PTFE performs exceptionally well at low temperatures. It maintains its strength, toughness, and flexibility down to cryogenic levels, making it suitable for applications as low as -200°C (-328°F).

Why Temperature Swings Matter

The most critical, real-world limitation is PTFE's rate of thermal expansion. As temperatures change, the PTFE seats and seals will expand or contract.

If this temperature swing is too large or too rapid (exceeding 180°C), the material's movement can compromise the valve's seal, leading to leakage. This is the most common cause of failure in applications with fluctuating temperatures.

Understanding the Trade-offs

Selecting a PTFE valve requires balancing its powerful advantages against its primary physical limitation.

Thermal Expansion vs. Sealing Integrity

The core trade-off is leveraging PTFE's chemical resistance and low friction while respecting its tendency to expand and contract. Stable operating temperatures are always preferable.

For applications with unavoidable temperature cycling, you must design the process to keep those swings within the material's tolerance to ensure a consistent, reliable seal.

Standard vs. Filled PTFE

To mitigate some of its mechanical limitations, PTFE is often mixed with fillers like glass or carbon.

These fillers can increase wear resistance and reduce thermal expansion, potentially offering better performance in demanding applications. However, they may alter the material's chemical resistance or temperature range, so the specific blend must be verified.

The Entire Valve Assembly

Remember that the PTFE seats and seals are only one part of the valve. The valve body, stem, and other components also have their own temperature and pressure limitations that must be respected for the safe operation of the entire assembly.

Making the Right Choice for Your Application

Use these guidelines to match the valve's capabilities to your operational needs.

- If your primary focus is stable, high-temperature service: Ensure your maximum operating temperature remains safely below the 260°C (500°F) continuous limit.

- If your primary focus is frequent and wide temperature cycling: Limit the temperature swings to below 180°C to maintain a reliable seal and prevent leakage over the valve's lifespan.

- If your primary focus is extreme low-temperature (cryogenic) service: PTFE is an excellent material choice, but you must verify the specifications for the entire valve assembly, not just the seals.

Understanding the interplay between PTFE's thermal properties and your specific operating conditions is the key to ensuring long-term valve reliability.

Summary Table:

| Aspect | Standard PTFE Ball Valve Limit | Critical Consideration |

|---|---|---|

| Max Continuous Temperature | +260°C (500°F) | Avoid deformation and loss of seal integrity |

| Min Temperature | -200°C (-328°F) | Excellent for cryogenic applications |

| Recommended Thermal Swing | < 180°C | Key to maintaining a reliable seal and preventing leakage |

Need a PTFE valve that stands up to your specific temperature demands?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication services, from prototypes to high-volume orders, ensure your valves deliver reliable performance under even the most challenging thermal conditions.

Contact us today to discuss your application requirements and let our experts help you select or custom-design the perfect PTFE solution.

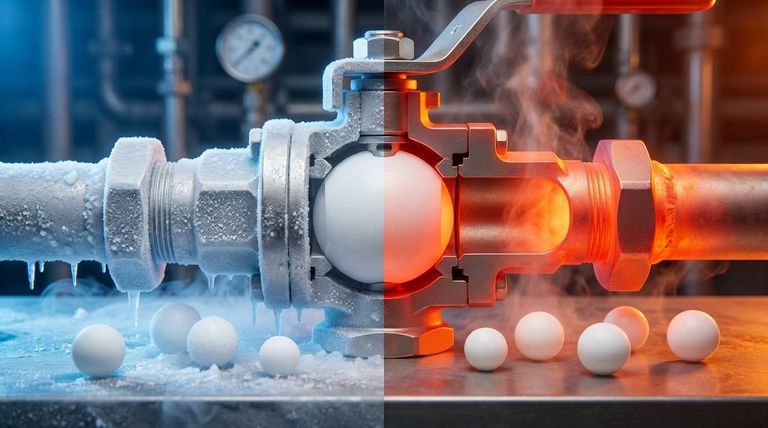

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the advantages of PTFE balls over metals or alloys? Superior Chemical & Friction Resistance

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- What are the available grades of PTFE balls? Choose the Right Grade for Your Application

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime