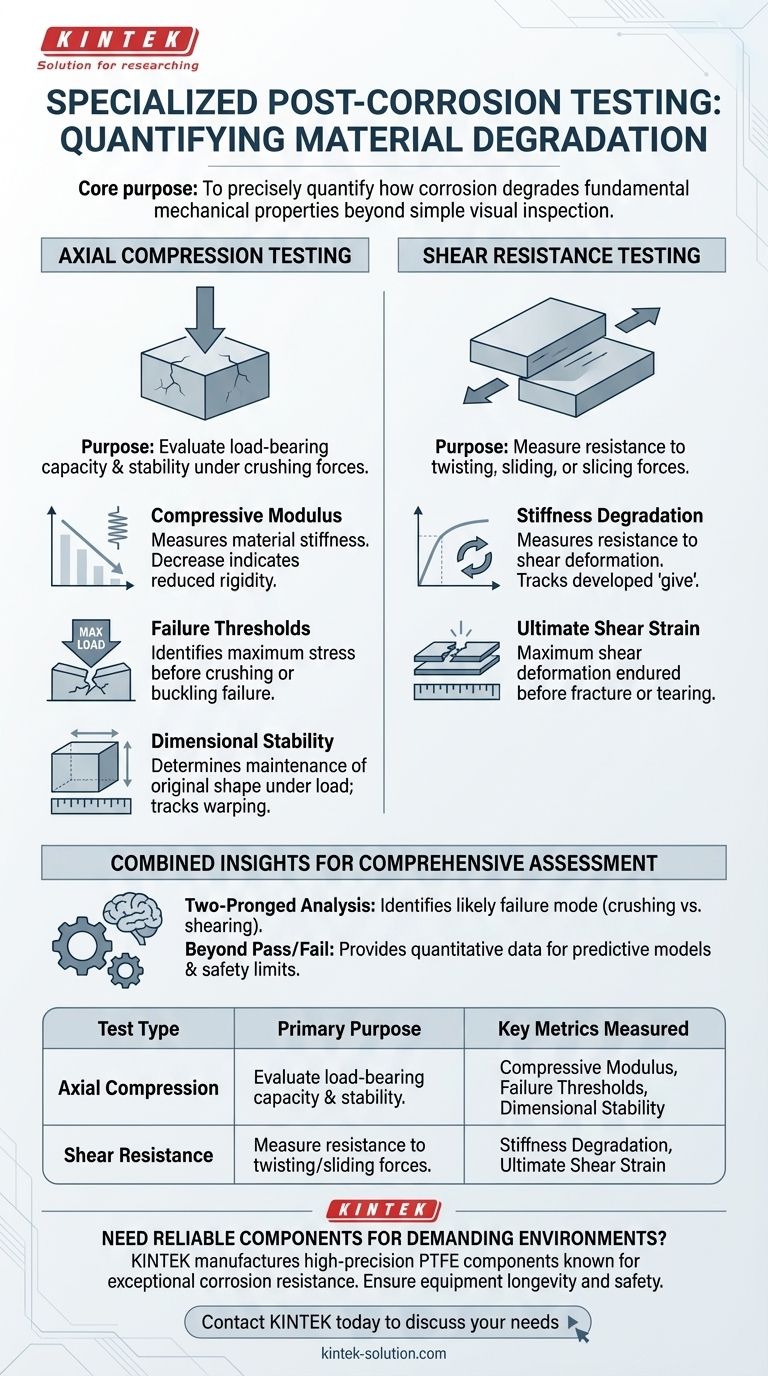

Following accelerated corrosion treatments, two primary forms of specialized mechanical testing were performed on the specimens. These were axial compression tests, designed to evaluate the material's load-bearing capacity and stability, and shear resistance tests, which measured its ability to resist twisting or sliding forces.

The core purpose of this post-corrosion testing is to move beyond simple visual inspection and precisely quantify how corrosion degrades a material's fundamental mechanical properties—specifically, its ability to resist crushing (compression) and deforming (shear) under load.

Analyzing Compressive Strength and Stability

The first major evaluation focused on how the material behaved under direct compressive forces, which is critical for any component that must bear a load without buckling.

The Purpose of Axial Compression Testing

This test involves applying a squeezing or crushing force along the primary axis of a specimen. It directly simulates the stresses on a structural support column or any component under a heavy load.

Key Metric: Compressive Modulus

The compressive modulus is a measure of the material's stiffness or rigidity when being compressed. A significant decrease in this value after corrosion indicates the material has become less stiff and will deform more easily under its designed load.

Key Metric: Failure Thresholds

This metric identifies the maximum compressive stress the material can withstand before it fails, either by crushing or buckling. This is the most direct measure of how corrosion has reduced the material's ultimate strength.

Key Metric: Dimensional Stability

This evaluation determines how well the specimen maintains its original shape and size under load. Corrosion can cause localized weaknesses that lead to premature bulging or warping, compromising the integrity of the entire structure.

Evaluating Resistance to Shear Forces

The second evaluation examined the material's response to shear stress. This is essential for components that experience torsional, twisting, or slicing forces, such as fasteners, beams, or mechanical joints.

The Purpose of Shear Resistance Testing

This test measures the material's ability to resist forces that cause its internal layers to slide past one another. It quantifies the degradation of the bonds that hold the material together.

Key Metric: Stiffness Degradation

Similar to the compressive modulus, shear stiffness measures resistance to deformation, but specifically for shear forces. Tracking its stiffness degradation reveals how much "give" the material has developed due to corrosion damage.

Key Metric: Ultimate Shear Strain

Ultimate shear strain represents the maximum amount of shear deformation the material can endure before it rips, tears, or fractures. A lower value after corrosion signifies a loss of ductility and an increased risk of brittle failure.

Understanding the Combined Insights

Performing only one of these tests would provide an incomplete picture of the material's degradation. The combination of both is what yields a comprehensive and reliable assessment.

A Two-Pronged Failure Analysis

A material might retain much of its compressive strength but become critically weak in shear, or vice versa. By testing both, engineers can identify the most likely mode of failure for a component in a real-world, corrosive environment.

Beyond a Simple Pass/Fail Result

These specialized tests provide quantitative data, not just a simple "it broke" observation. This data is essential for creating accurate predictive models, setting realistic maintenance schedules, and establishing safe operational limits for corroded components.

How This Data Informs Engineering Decisions

The specific focus of your analysis will determine which test results are most critical for your application.

- If your primary focus is structural load-bearing capacity: The axial compression test data, particularly the failure thresholds, is your most critical indicator of safety and performance.

- If your primary focus is component rigidity and resistance to torsion or vibration: The shear resistance test, specifically the stiffness degradation metric, will best inform your analysis of performance degradation.

- If your primary focus is predicting overall service life: You must synthesize the results from both tests to build a complete profile of how the material weakens over time.

This rigorous, multi-faceted testing approach provides the precise engineering data needed to confidently assess the true impact of corrosion on material integrity.

Summary Table:

| Test Type | Primary Purpose | Key Metrics Measured |

|---|---|---|

| Axial Compression | Evaluate load-bearing capacity and stability under crushing forces. | Compressive Modulus, Failure Thresholds, Dimensional Stability |

| Shear Resistance | Measure resistance to twisting, sliding, or slicing forces. | Stiffness Degradation, Ultimate Shear Strain |

Need Reliable Components for Demanding Environments?

The specialized testing described quantifies how corrosion weakens materials. For applications where chemical resistance and material integrity are non-negotiable—such as in semiconductor, medical, laboratory, and industrial settings—the right components are critical.

KINTEK manufactures high-precision PTFE components (including seals, liners, and custom labware) known for their exceptional corrosion resistance and durability. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Ensure your equipment's longevity and safety. Contact KINTEK today to discuss your component needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications