To machine PTFE successfully, you must fundamentally shift your approach from that used for metals. Success requires exceptionally sharp tooling, high feed rates to minimize heat transfer, extremely light clamping pressure to prevent deformation, and aggressive use of coolant to manage the material's significant thermal expansion.

The central challenge of machining PTFE is not the cutting itself—the material is soft and cuts easily. The true difficulty lies in controlling the material's reaction to heat and pressure to maintain dimensional accuracy and achieve a clean surface finish.

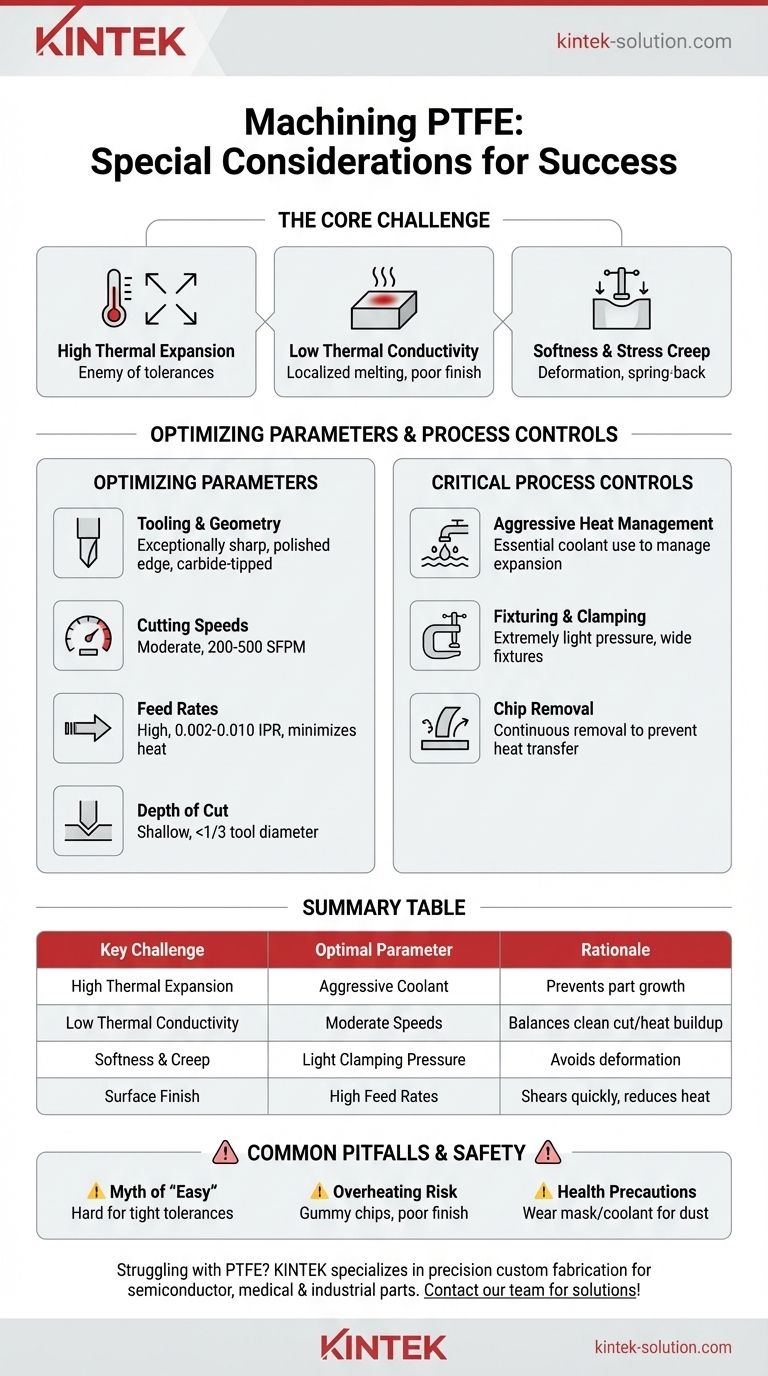

The Core Challenge: PTFE's Unique Material Properties

Before adjusting machine settings, you must understand why PTFE (Polytetrafluoroethylene) behaves the way it does. Its properties demand a unique strategy that prioritizes finesse over force.

High Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among plastics. Even a small amount of heat generated during cutting will cause the part to expand significantly.

This expansion is the primary enemy of tight tolerances. A part machined to spec while warm will be undersized once it cools to ambient temperature.

Low Thermal Conductivity

Compounding the problem, PTFE is an excellent thermal insulator. Heat introduced at the cutting edge does not dissipate quickly throughout the material.

Instead, heat concentrates right where you are cutting, leading to localized melting, gummy chips, and a poor surface finish if not managed properly.

Softness and Stress Creep

PTFE is an exceptionally soft material that will deform, or "creep," under sustained pressure.

Standard clamping pressures used for metals will compress a PTFE workpiece. When the part is released from the fixture, it will spring back, resulting in a dimensionally inaccurate final product.

Optimizing Your Machining Parameters

Your tooling and machine settings must be chosen specifically to counteract PTFE's challenging properties. The goal is always to produce a clean chip with minimal heat input and part deflection.

Tool Selection and Geometry

Your cutting tools must be impeccably sharp. A honed, polished cutting edge is non-negotiable for shearing the material cleanly rather than plowing through it.

Carbide-tipped tools are highly recommended for their ability to hold a sharp edge and minimize frictional heat. Ensure tools have generous back and side clearance angles to reduce rubbing.

Cutting Speeds

Moderate cutting speeds, typically in the range of 200 to 500 surface feet per minute (SFPM), are a safe starting point.

Running too fast generates excessive heat, while running too slow can cause the tool to rub instead of cut. The key is to find the sweet spot that produces a clean chip without overheating the part.

Feed Rates

Generally, high feed rates are preferred, often between 0.002 and 0.010 inches per revolution.

A higher feed rate moves the cutting edge through the material quickly, minimizing the time available for heat to transfer into the workpiece. For fine finishing passes, you may need to reduce the feed rate for better control.

Depth of Cut

Use a shallow depth of cut. A good rule of thumb is to not exceed one-third of your cutting tool's diameter. This reduces cutting forces and minimizes heat generation on any single pass.

Critical Process Controls

How you handle the material before and during the cut is just as important as the speeds and feeds you use.

Aggressive Heat Management

The use of a coolant or lubricant is essential for most PTFE machining operations. A flood coolant system is highly effective at extinguishing heat at the point of the cut and washing away chips.

This is the single most effective way to manage thermal expansion and prevent the material from becoming gummy.

Fixturing and Clamping Pressure

Apply the absolute minimum clamping pressure required to hold the workpiece securely. Use fixtures with wide surface areas to distribute the clamping force and avoid distorting the part.

Over-tightening is a common and critical mistake that guarantees dimensional inaccuracy. Always avoid excessive pressure and vibration.

Swarf (Chip) Removal

Ensure continuous and effective removal of chips (swarf). Hot chips left sitting on the part's surface will transfer heat back into it, undermining your efforts to keep it cool.

Common Pitfalls to Avoid

Understanding the risks and common mistakes is crucial for consistent success.

The Myth of "Easy" Machining

While PTFE is soft and requires little horsepower to cut, it is one of the more difficult polymers to machine to a tight tolerance. Its properties make it unforgiving of poor technique.

The Risk of Overheating

If you see a poor, torn surface finish or find your chips are gummy and sticking to the tool, your process is generating too much heat. This is an immediate sign that you must adjust your speed, feed, or coolant application.

Health and Safety Precautions

Machining PTFE can produce fine dust particles. It is a critical safety practice to wear a mask or ensure the work is performed under coolant to prevent the inhalation of this dust.

Making the Right Choice for Your Goal

Your specific approach may need slight adjustments based on the primary objective for your component.

- If your primary focus is tight tolerances (+/- 0.002"): Prioritize thermal stability above all else by using generous flood coolant and allowing the part to normalize to room temperature before taking final measurements.

- If your primary focus is a superior surface finish: Use brand new or freshly sharpened carbide tools with a highly polished cutting edge and consider a slower, lighter finishing pass.

- If your primary focus is production speed: Maximize feed rates and ensure your coolant and chip evacuation systems are robust enough to keep the cutting zone clear and cool.

Ultimately, mastering the machining of PTFE comes from respecting its unique properties and adapting your process to work with the material, not against it.

Summary Table:

| Key Challenge | Optimal Parameter | Rationale |

|---|---|---|

| High Thermal Expansion | Aggressive Coolant | Prevents part growth and ensures dimensional stability after cooling. |

| Low Thermal Conductivity | Moderate Speeds (200-500 SFPM) | Balances clean cutting with minimal heat buildup at the tool edge. |

| Softness & Creep | Light Clamping Pressure | Avoids part deformation and spring-back for accurate final dimensions. |

| Surface Finish | High Feed Rates (0.002-0.010 IPR) | Shears material quickly, reducing heat transfer and gumminess. |

Struggling with PTFE part accuracy or finish? KINTEK specializes in precision machining of PTFE components like seals, liners, and labware for semiconductor, medical, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures your parts meet tight tolerances and superior surface quality. Contact our team today to discuss your project and leverage our tailored solutions for reliable, high-performance PTFE parts!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support