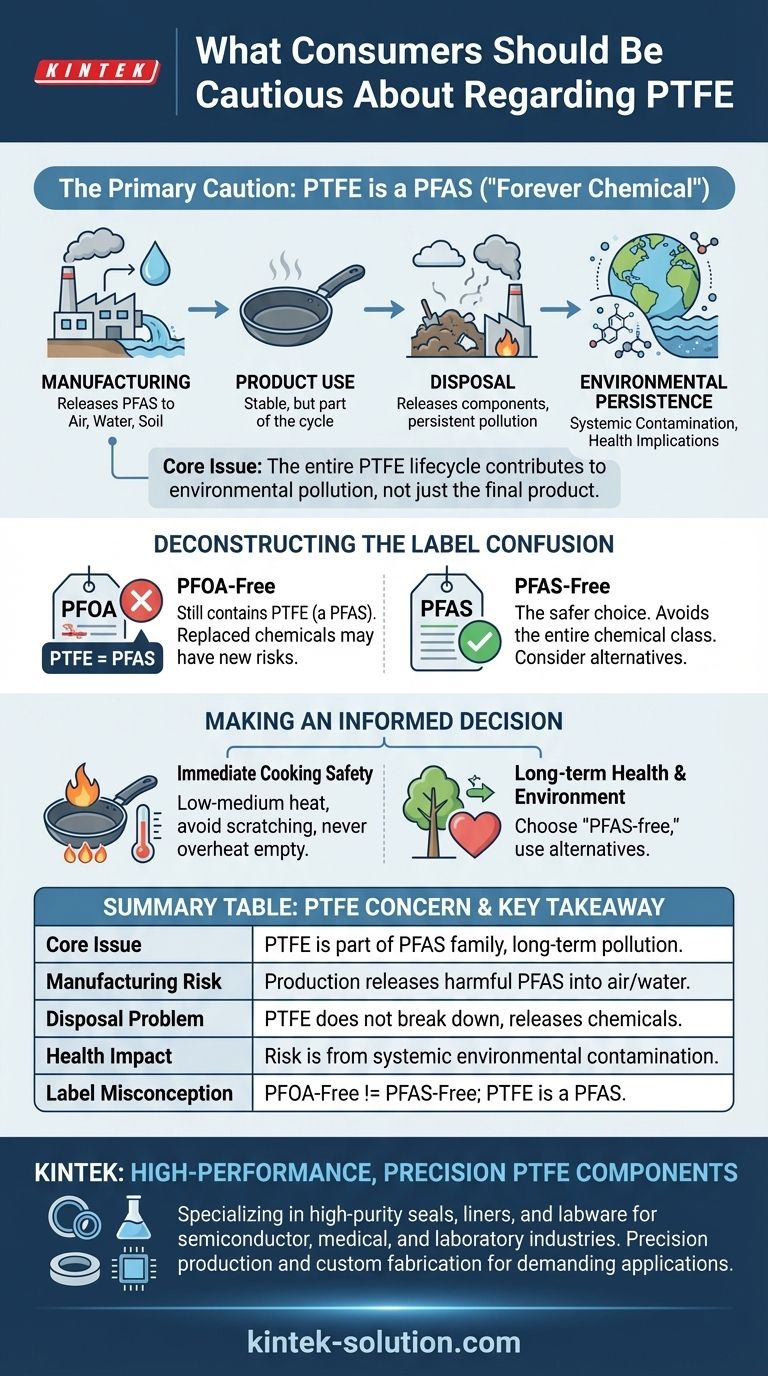

Your primary caution regarding PTFE should be its connection to the broader family of PFAS "forever chemicals." While the solid PTFE coating on a product is generally stable and safe under normal use, its manufacturing and disposal processes contribute to persistent environmental pollution that has significant health implications.

The core issue isn't necessarily the finished product in your home, but the entire lifecycle of PTFE. Focusing on whether a product is "PFAS-free" is a more reliable indicator of safety and environmental responsibility than simply looking for a "PFOA-free" label.

Deconstructing the PTFE Problem

To understand the risks, it's crucial to look beyond the final product and see where PTFE comes from and where it goes. The concerns are less about acute, immediate danger and more about long-term, systemic contamination.

The Real Issue: The PFAS Lifecycle

PTFE is a fluoropolymer, which places it in the large family of man-made chemicals known as PFAS (per- and polyfluoroalkyl substances). These are often called "forever chemicals" because they do not break down naturally in the environment.

The manufacturing process for PTFE has historically involved, and can still create, other harmful PFAS chemicals that are released into the air, water, and soil. This contamination is the primary source of public health concern.

Disposal and Environmental Persistence

When a PTFE-coated product reaches the end of its life, the problem continues. In landfills or through incineration, the PTFE can degrade and release its chemical components back into the environment, contributing to the cycle of PFAS pollution.

This persistence means that the chemicals accumulate in the environment, in wildlife, and ultimately, in humans, where they are linked to a range of health issues.

Understanding the True Health Concerns

While much of the focus has been on cookware, the danger is not about cooking an egg on a non-stick pan. The risk is systemic and tied to the environmental contamination caused by the entire class of chemicals.

Production's Environmental Footprint

The production facilities that create PTFE and other PFAS have been identified as major sources of environmental contamination, affecting the drinking water and health of surrounding communities. This is an unavoidable consequence of producing the chemical.

From "PFOA-Free" to "PFAS-Free"

For years, the main concern was PFOA, a particularly toxic type of PFAS used to manufacture PTFE. Most companies have phased out PFOA, leading to the "PFOA-Free" labels you see today.

However, this claim can be misleading. While PFOA may be gone, the product still contains PTFE, which is itself a PFAS. Furthermore, the new chemicals used to replace PFOA in manufacturing may have their own, not-yet-fully-understood health risks.

Making an Informed Decision

Your choice as a consumer has an impact that extends far beyond your kitchen. Until stricter regulations are in place, the responsibility falls on individuals to understand the full context.

- If your primary focus is immediate cooking safety: Using your existing PTFE pan at low-to-medium temperatures and ensuring the coating is not scratched or flaking is generally considered safe. Never overheat an empty non-stick pan.

- If your primary focus is long-term health and environmental impact: Seek out products explicitly labeled as "PFAS-free." This ensures the product is free from PTFE and the entire class of associated forever chemicals. Consider alternatives like cast iron, stainless steel, glass, and ceramic.

Ultimately, making an informed choice means looking past simple marketing claims and considering the total lifecycle impact of the products you buy.

Summary Table:

| PTFE Concern | Key Takeaway |

|---|---|

| Core Issue | PTFE is part of the PFAS family, contributing to long-term environmental pollution. |

| Manufacturing Risk | Production can release harmful PFAS chemicals into air and water. |

| Disposal Problem | PTFE does not break down and can release chemicals when discarded. |

| Health Impact | Risk is from systemic environmental contamination, not typical use. |

| Label Misconception | 'PFOA-Free' does not mean 'PFAS-Free'; PTFE itself is a PFAS. |

Need high-performance, precision-engineered PTFE components without the environmental concerns? KINTEK specializes in manufacturing high-purity PTFE seals, liners, and labware for the semiconductor, medical, and laboratory industries. Our commitment to precision production and custom fabrication—from prototypes to high-volume orders—ensures you get reliable components for your most demanding applications. Contact our experts today to discuss your specific requirements and discover the KINTEK difference.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support