The primary role of low friction in Medical Grade PTFE Liners is to enable effortless and precise device movement within the body. This property dramatically reduces the force needed to navigate complex anatomical pathways, which directly enhances procedural success, minimizes tissue trauma, and improves patient safety. This characteristic is not merely an enhancement; it is fundamental to the performance of advanced catheters and delivery systems.

Low friction is not just a material property of Medical Grade PTFE; it is the core engineering principle that translates into tangible clinical benefits. It converts a physician's physical effort into precise control, directly impacting patient outcomes and device reliability.

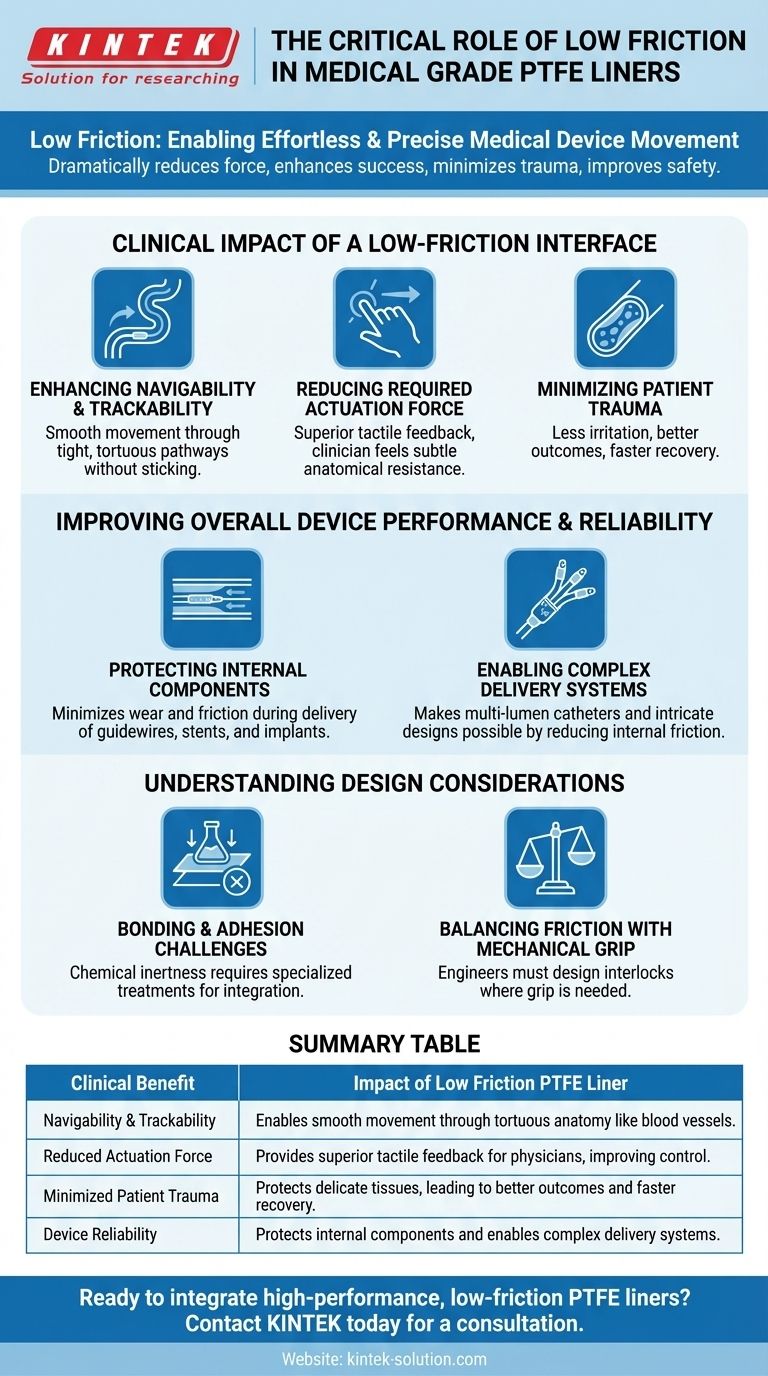

The Clinical Impact of a Low-Friction Interface

The value of a low-friction liner is most evident when observing its direct effects during a medical procedure. It fundamentally changes how a device interacts with both the patient's anatomy and the clinician's hands.

Enhancing Navigability and "Trackability"

PTFE's ultra-low coefficient of friction minimizes the resistance a device encounters as it moves through the body. This is especially critical in vascular applications.

This property, often called trackability, allows a catheter to glide smoothly through tight and tortuous pathways, like blood vessels in the brain or heart, without sticking or buckling.

Reducing Required Actuation Force

Reduced friction means the physician needs to apply significantly less force to advance, retract, or rotate the device.

This reduction in force provides superior tactile feedback. It allows the clinician to feel subtle changes in resistance from the patient's anatomy, rather than being masked by friction from the device itself.

Minimizing Patient Trauma

A device with a smooth, low-friction surface is far less likely to irritate or damage the delicate inner lining of blood vessels and other tissues.

This directly contributes to better patient outcomes, reduces discomfort, and can lead to faster recovery times.

Improving Overall Device Performance and Reliability

Beyond the immediate clinical feel, the low-friction nature of PTFE liners is a key enabler for sophisticated and dependable medical technology.

Protecting Internal Components

The liner creates a smooth, protective channel for any other instruments or devices passing through it.

Guidewires, stents, balloons, or other implants can be deployed more reliably and with less risk of damage because the liner minimizes wear and friction during delivery.

Enabling Complex Delivery Systems

Modern medical devices are increasingly complex. Low friction is often the key that makes these designs possible.

It allows engineers to create multi-lumen catheters or intricate systems for deploying delicate implants, which would otherwise fail due to the high internal friction between moving parts.

Understanding the Design Considerations

While incredibly beneficial, the ultra-low friction of PTFE is a powerful property that must be accounted for in the total device design. It is not a "drop-in" solution without engineering considerations.

Bonding and Adhesion Challenges

The same chemical inertness that makes PTFE's surface low-friction also makes it notoriously difficult to bond to other materials.

Specialized surface treatments, such as sodium etching, are often required to integrate the liner into a composite catheter shaft. This adds critical steps and complexity to the manufacturing process.

Balancing Friction with Mechanical Grip

In some applications, a certain amount of friction is desired for control or anchoring.

Engineers must design mechanical interlocks or use different materials for sections where grip, not slip, is the primary requirement. The liner's properties must be managed as part of a complete system.

Making the Right Choice for Your Goal

The low-friction characteristic of a PTFE liner should be leveraged strategically based on the primary objective of your medical device.

- If your primary focus is navigability through highly tortuous anatomy (e.g., neurovascular catheters): Prioritize the liner with the lowest possible coefficient of friction to maximize trackability and reduce actuation force.

- If your primary focus is delivering a secondary device or implant (e.g., a stent delivery system): Focus on the liner's consistency and smoothness to ensure predictable deployment and prevent damage to the implant.

- If your primary focus is robust manufacturability: You must account for the specialized surface treatments required to achieve a durable bond between the low-friction PTFE liner and other layers of your device.

Ultimately, leveraging the low-friction properties of PTFE is a strategic design choice that directly translates engineering specifications into superior clinical performance.

Summary Table:

| Clinical Benefit | Impact of Low Friction PTFE Liner |

|---|---|

| Navigability & Trackability | Enables smooth movement through tortuous anatomy like blood vessels. |

| Reduced Actuation Force | Provides superior tactile feedback for physicians, improving control. |

| Minimized Patient Trauma | Protects delicate tissues, leading to better outcomes and faster recovery. |

| Device Reliability | Protects internal components and enables complex delivery systems. |

Ready to integrate high-performance, low-friction PTFE liners into your medical devices?

At KINTEK, we specialize in the precision manufacturing of Medical Grade PTFE components, including liners, seals, and custom labware. Our expertise is critical for the semiconductor, medical, and laboratory industries, where reliability is non-negotiable.

We partner with you from prototype to high-volume production, ensuring your devices achieve the precise navigability and clinical performance they demand. Let's discuss how our custom PTFE solutions can enhance your next project.

Contact KINTEK today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support