In the future of engineering, CNC machined Polytetrafluoroethylene (PTFE) is set to become an indispensable material for innovation. Its pivotal role is driven by a unique combination of extreme properties that align perfectly with the demands of advanced industries like aerospace, medicine, and electronics. The precision of CNC machining unlocks these properties, enabling the creation of complex components that solve critical design challenges.

The core takeaway is that while PTFE's raw properties are exceptional, it is the precision and repeatability of CNC machining that transforms it from a useful polymer into a cornerstone material for high-stakes, future-focused engineering applications.

Why PTFE is a Cornerstone Material

The value of PTFE is rooted in a set of distinct physical and chemical properties that are difficult to find in a single material. Understanding these fundamentals is key to appreciating its role.

Unmatched Chemical Inertness

PTFE is one of the most non-reactive substances known. This means it can withstand highly corrosive chemicals without degrading.

This property makes it essential for components in chemical processing, medical devices that must not react with bodily fluids, and food-grade applications.

Extreme Temperature Stability

The material maintains its integrity and performance across a very wide temperature range. It is highly resistant to heat and does not become brittle at cryogenic temperatures.

This stability is critical for seals, gaskets, and components used in aerospace engines and industrial machinery where temperature fluctuations are common.

The Lowest Coefficient of Friction

Often recognized by its brand name Teflon, PTFE has an extremely low coefficient of friction. It is one of the "slipperiest" solid materials in existence.

This makes it an ideal choice for creating non-stick surfaces, low-friction bearings, and seals that reduce wear and improve energy efficiency.

Superior Electrical Insulation

PTFE is an excellent electrical insulator with a high dielectric strength. It does not conduct electricity and can resist high voltages.

This characteristic is vital for protecting sensitive electronics, especially in high-frequency applications where signal integrity is paramount.

The Role of CNC Machining in Unlocking PTFE's Potential

PTFE's raw potential is only fully realized when it can be shaped into precise, functional parts. This is where computer numerical control (CNC) machining becomes critical.

Achieving Uncompromising Precision

Industries like aerospace and medicine demand components with extremely tight tolerances. CNC machining provides the digital precision required to consistently produce these parts.

This process transforms stock rods or sheets of PTFE into complex components that meet exact design specifications, which is impossible with molding alone.

Enabling Complex Geometries

Modern design problems often require innovative, non-standard component shapes. CNC machining allows for the creation of intricate geometries and custom features.

This adaptability gives engineers the freedom to design without being constrained by the limitations of traditional manufacturing methods.

Key Industries Driving Future Demand

The adoption of CNC machined PTFE is not theoretical; it is already being driven by the practical needs of the world's most demanding sectors.

Aerospace and Aviation

In this sector, every component must be reliable under extreme conditions. PTFE is used for high-performance seals, gaskets, and wire insulation due to its heat and chemical resistance.

Medical and Life Sciences

Because PTFE is biocompatible and can be sterilized, it is a go-to material for medical implants, surgical instruments, and fluid-handling components.

Automotive and Electronics

In automotive, PTFE parts enhance performance and durability by reducing friction. In electronics, its insulating properties protect delicate circuits and high-frequency connectors.

Understanding the Trade-offs and Limitations

To use a material effectively, one must understand not only its strengths but also its weaknesses. PTFE is a specialized polymer, not a universal solution.

Relatively Low Mechanical Strength

PTFE is a soft material and can be prone to "creep," or deformation under a sustained load. It is not suitable for high-load structural applications.

Higher Material Cost

As a high-performance polymer, PTFE is more expensive than commodity plastics like polyethylene or polypropylene. Its use must be justified by specific performance requirements.

Machining Challenges

While considered easy to machine, PTFE's softness can create challenges. It requires specialized tooling and techniques to avoid burrs and hold tight tolerances, adding a layer of manufacturing complexity.

Making the Right Choice for Your Design

Your application's primary goal will determine if CNC machined PTFE is the correct choice.

- If your primary focus is reliability in harsh environments: Leverage PTFE's unmatched chemical and thermal resistance for seals, linings, and fluid-handling components.

- If your primary focus is precision medical or electronic parts: Utilize its biocompatibility and insulating properties to create complex, non-reactive components with CNC accuracy.

- If your primary focus is reducing friction and wear: Design bearings, bushings, and non-stick surfaces that capitalize on PTFE's exceptionally low friction coefficient.

By understanding both its powerful capabilities and its specific limitations, you can deploy CNC machined PTFE to solve tomorrow's most demanding engineering problems.

Summary Table:

| Key Property | Benefit for Engineering | Common Applications |

|---|---|---|

| Chemical Inertness | Resists corrosive substances | Seals, liners, fluid-handling systems |

| Extreme Temperature Stability | Performs from cryogenic to high heat | Aerospace gaskets, industrial seals |

| Low Coefficient of Friction | Reduces wear and energy loss | Bearings, bushings, non-stick surfaces |

| Superior Electrical Insulation | Protects sensitive electronics | High-frequency connectors, insulators |

| Biocompatibility | Safe for medical use | Implants, surgical tools, labware |

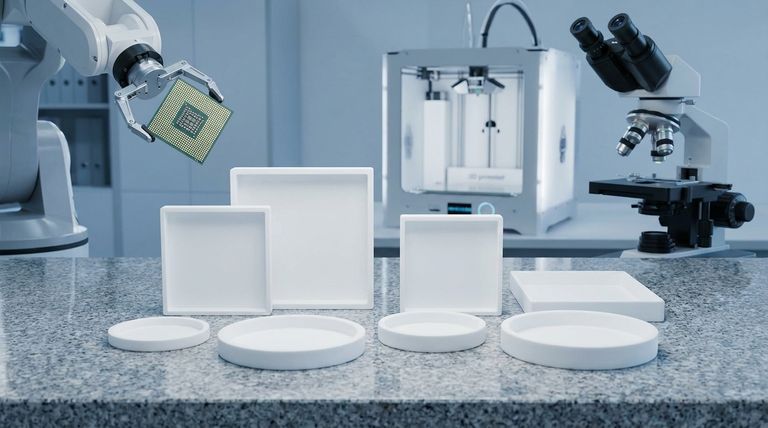

Ready to leverage CNC machined PTFE for your next project? KINTEK specializes in precision PTFE components for semiconductor, medical, laboratory, and industrial applications. We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for performance in demanding environments. Contact our experts today to discuss how our PTFE solutions can solve your critical design challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments