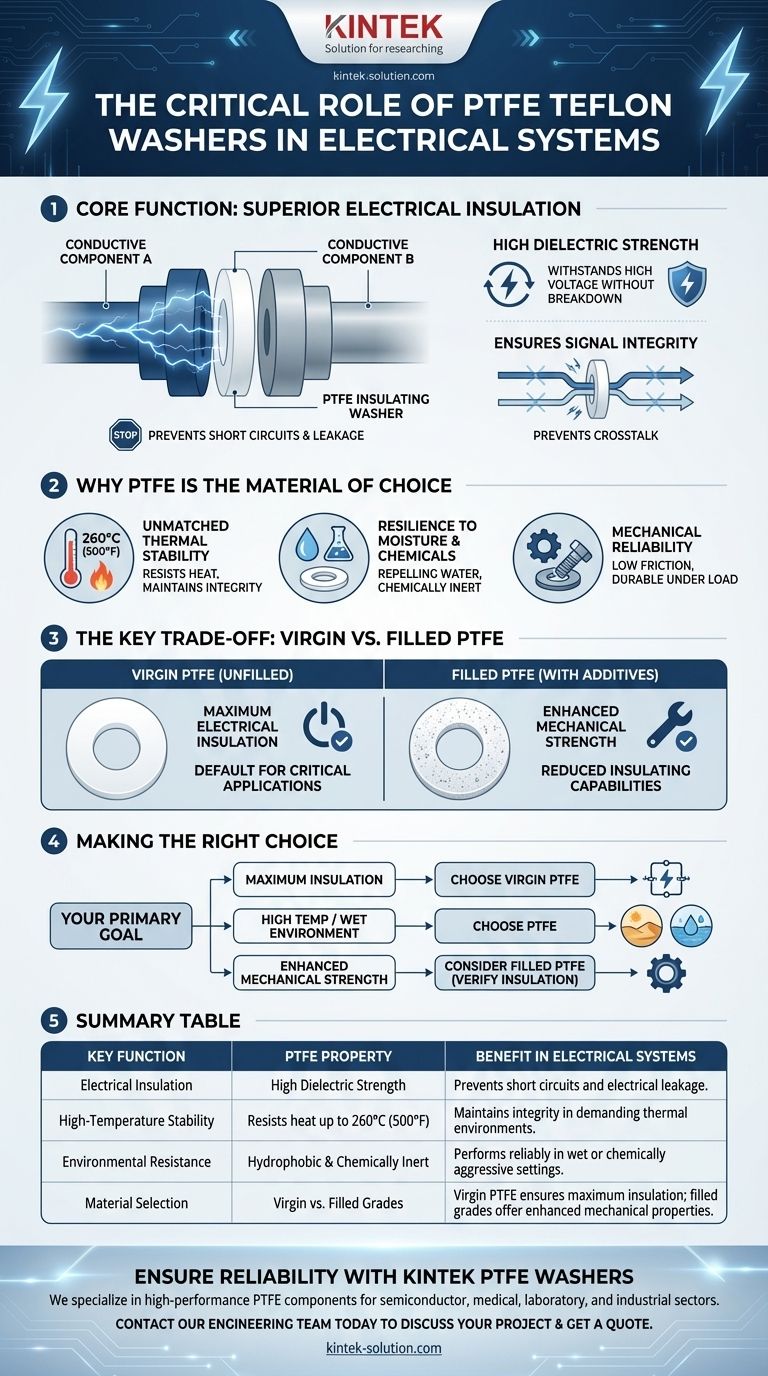

In electrical systems, PTFE Teflon washers serve one primary, critical function: electrical insulation. They are specifically engineered to block the flow of electric current between conductive components, such as in terminals and connectors. This prevents dangerous short circuits, protects sensitive electronics from electrical leakage, and ensures the overall safety and reliability of the system.

The true value of a PTFE washer in an electrical context is not just its ability to insulate, but its capacity to maintain that insulation under extreme conditions—such as high heat, moisture, and chemical exposure—where lesser materials would degrade and fail.

The Core Function: Superior Electrical Insulation

At its most fundamental level, an insulator is a material that resists the flow of electricity. PTFE (Polytetrafluoroethylene) is one of the most effective insulating polymers available, making it an ideal material for washers in demanding electrical applications.

Preventing Electrical Conduction

A PTFE washer placed between a metallic screw and a chassis, or between two terminals, creates a non-conductive barrier. This physical separation is essential for preventing short circuits, where current bypasses its intended path, which can cause component damage or system failure.

High Dielectric Strength

PTFE exhibits superb dielectric strength. This is a measure of a material's ability to withstand a high voltage electrical field without breaking down and starting to conduct electricity. This property is crucial for ensuring reliable performance, especially in high-voltage applications.

Ensuring Signal Integrity

In complex electronics, preventing electrical "crosstalk" or interference between adjacent conductors is vital. By providing a stable insulating barrier, PTFE washers help maintain the integrity of electrical signals, ensuring the accurate and efficient operation of delicate components.

Why PTFE is the Material of Choice

Many materials can act as insulators, but PTFE is frequently specified because its other inherent properties support its insulating function in harsh operating environments.

Unmatched Thermal Stability

Electrical components often generate significant heat. PTFE is renowned for its high-temperature resistance, maintaining its structural and electrical integrity at continuous service temperatures up to 260°C (500°F). Other insulators, like many rubbers, would melt or degrade under these conditions.

Resilience to Moisture and Chemicals

PTFE is hydrophobic, meaning it repels water and is non-absorbent. Since moisture can create conductive paths and compromise insulation, this property is a significant advantage. Furthermore, its chemical inertness means it won't be degraded by oils, fuels, or other corrosive substances common in automotive and industrial settings.

Mechanical Reliability

While its insulating properties are primary, PTFE's low-friction, non-stick surface is beneficial in connectors that are frequently mated and unmated. Its durability ensures it won't easily crack or deform under the compressive load of a fastened screw or bolt, maintaining the insulating gap.

Understanding the Key Trade-off: Virgin vs. Filled PTFE

While PTFE is an exceptional material, it's critical to understand how its composition can affect its performance in an electrical system. This is the most common point of failure in material selection.

Virgin PTFE for Maximum Insulation

Virgin PTFE, which is pure and contains no additives, exhibits the highest dielectric strength and the best insulating properties. It is the default choice for applications where electrical insulation is the most critical requirement.

Filled PTFE for Mechanical Strength

Filled PTFE grades incorporate additives like glass, carbon, or bronze to enhance mechanical properties such as compressive strength or wear resistance. However, these fillers can significantly reduce the material's insulating capabilities. Using a filled PTFE washer in a critical insulating application is a common mistake that can compromise system safety and performance.

Making the Right Choice for Your Application

Selecting the correct washer is a matter of aligning the material's properties with the primary goal of your design.

- If your primary focus is maximum electrical insulation: Always specify a virgin (unfilled) grade PTFE washer to guarantee the highest dielectric strength.

- If your application operates at high temperatures or in wet environments: PTFE is an excellent choice, as its thermal stability and hydrophobic nature will preserve its insulating properties.

- If the component requires enhanced mechanical strength (e.g., wear resistance): You may consider a filled PTFE, but you must verify that its reduced electrical properties still meet your system's minimum insulation requirements.

Ultimately, choosing the right material ensures the long-term safety, efficiency, and reliability of your electrical system.

Summary Table:

| Key Function | PTFE Property | Benefit in Electrical Systems |

|---|---|---|

| Electrical Insulation | High Dielectric Strength | Prevents short circuits and electrical leakage. |

| High-Temperature Stability | Resists heat up to 260°C (500°F) | Maintains integrity in demanding thermal environments. |

| Environmental Resistance | Hydrophobic & Chemically Inert | Performs reliably in wet or chemically aggressive settings. |

| Material Selection | Virgin vs. Filled Grades | Virgin PTFE ensures maximum insulation; filled grades offer enhanced mechanical properties. |

Ensure the Reliability of Your Electrical Systems with KINTEK PTFE Washers

Are you designing for high-voltage, high-temperature, or chemically harsh environments? The right PTFE washer is critical for preventing system failure.

KINTEK specializes in manufacturing high-performance PTFE components, including precision washers, seals, and labware. We understand that your application demands more than just a part—it requires a solution that guarantees safety and performance.

We serve the semiconductor, medical, laboratory, and industrial sectors, providing:

- Virgin PTFE Washers: For maximum dielectric strength and superior insulation.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Expert Material Guidance: Helping you select the right grade (virgin or filled) for your specific electrical and mechanical requirements.

Don't let component failure compromise your design. Contact our engineering team today to discuss your project and receive a quote.

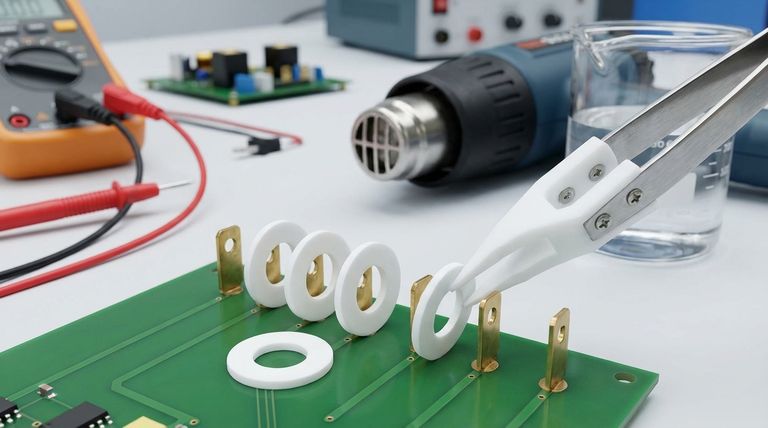

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support