To complement custom Teflon parts, engineers often turn to materials like polycarbonate components, nylon parts, and metal-bonded Teflon. These related products are chosen to provide structural strength, rigidity, and impact resistance—properties where Teflon's unique characteristics, such as its softness and low friction, may not be sufficient for the entire assembly.

The core principle is that while Teflon (PTFE) provides an unparalleled low-friction and chemically inert surface, it often requires integration with stronger materials to create a functional, durable, and structurally sound system.

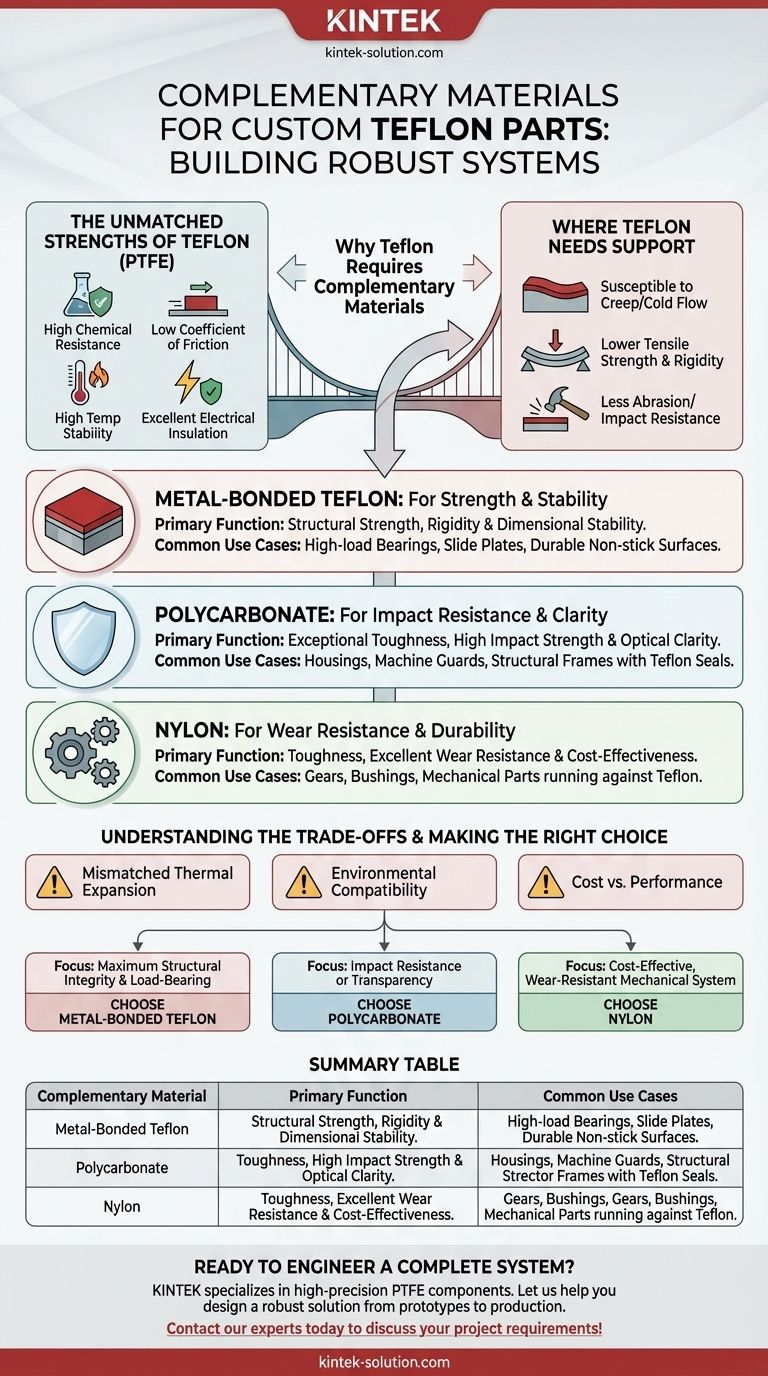

Why Teflon Requires Complementary Materials

Teflon is a high-performance polymer prized for specific, powerful characteristics. However, these same properties create limitations that must be addressed by other materials in an assembly.

The Unmatched Strengths of Teflon

Custom Teflon parts are specified for their remarkable combination of properties. They offer extremely high chemical resistance, a very low coefficient of friction, stability at high temperatures, and excellent electrical insulation.

This makes them ideal for seals, gaskets, bearings, and linings in aggressive environments found in aerospace, chemical processing, and electronics.

Where Teflon Needs Support

Despite its strengths, Teflon is a relatively soft material. It can be susceptible to "creep" or cold flow under load and has lower tensile strength and rigidity compared to engineering plastics or metals.

For a complete mechanical assembly, you need components that can bear structural loads, maintain precise dimensions under stress, and resist abrasion or impact.

Key Complementary Materials and Their Roles

Choosing the right partner material depends entirely on what functional gap you need to fill. Each option provides a different set of properties to balance the Teflon component.

Metal-Bonded Teflon: For Strength and Stability

This involves bonding a layer of Teflon to a rigid metal substrate, such as steel or aluminum. This composite part leverages the best of both materials.

You get the strength, rigidity, and dimensional stability of the metal core combined with the low-friction, non-stick surface of Teflon. This is ideal for high-load bearings, slide plates, and durable non-stick surfaces.

Polycarbonate: For Impact Resistance and Clarity

Polycarbonate is an engineering plastic known for its exceptional toughness, high impact strength, and optical clarity.

It is often used for housings, machine guards, or structural bodies that contain Teflon seals or bearings. It provides the robust structural frame while the Teflon part handles sealing or low-friction movement.

Nylon: For Wear Resistance and Durability

Nylon is a versatile and cost-effective material known for its toughness and excellent wear resistance.

It is frequently used for gears, bushings, and other mechanical parts that may run against a Teflon surface. This pairing creates a low-friction, self-lubricating system that is both durable and quiet.

Understanding the Trade-offs

Combining materials requires careful engineering consideration to ensure the final assembly performs as expected and doesn't fail prematurely.

Mismatched Thermal Expansion

Teflon has a significantly higher coefficient of thermal expansion than metals and many other plastics. In applications with wide temperature fluctuations, this difference must be accounted for in the design to prevent stress, warping, or delamination in bonded parts.

Environmental Compatibility

While Teflon is nearly chemically inert, its companion materials are not. Polycarbonate and nylon have specific chemical vulnerabilities. You must ensure that any complementary material is also compatible with the application's chemical and thermal environment.

Cost vs. Performance

Creating composite parts like metal-bonded Teflon or using high-performance plastics like polycarbonate increases the overall cost. This investment must be justified by the need for higher load capacity, greater durability, or other specific performance requirements that Teflon alone cannot meet.

Making the Right Choice for Your Application

The optimal material combination is dictated by the primary demand of your design.

- If your primary focus is maximum structural integrity and load-bearing: Metal-bonded Teflon provides the best solution by combining Teflon's surface properties with a rigid metal backbone.

- If your primary focus is impact resistance or transparency: Pair Teflon components with polycarbonate for structural parts like housings or covers.

- If your primary focus is a cost-effective, wear-resistant mechanical system: Using nylon for gears or bushings that interact with Teflon parts offers a balanced and reliable solution.

By thoughtfully selecting complementary materials, you leverage Teflon's unique advantages while engineering a complete and robust final product.

Summary Table:

| Complementary Material | Primary Function | Common Use Cases |

|---|---|---|

| Metal-Bonded Teflon | Structural strength & stability | High-load bearings, slide plates |

| Polycarbonate | Impact resistance & clarity | Housings, machine guards, structural frames |

| Nylon | Wear resistance & durability | Gears, bushings, mechanical parts |

Ready to engineer a complete system that leverages the strengths of Teflon and its complementary materials?

At KINTEK, we specialize in manufacturing high-precision custom PTFE (Teflon) components like seals, liners, and labware. We understand the critical need to pair them with the right materials for structural integrity and performance in the semiconductor, medical, laboratory, and industrial sectors.

Let us help you design and fabricate a robust solution—from prototypes to high-volume production.

Contact our experts today to discuss your project requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support