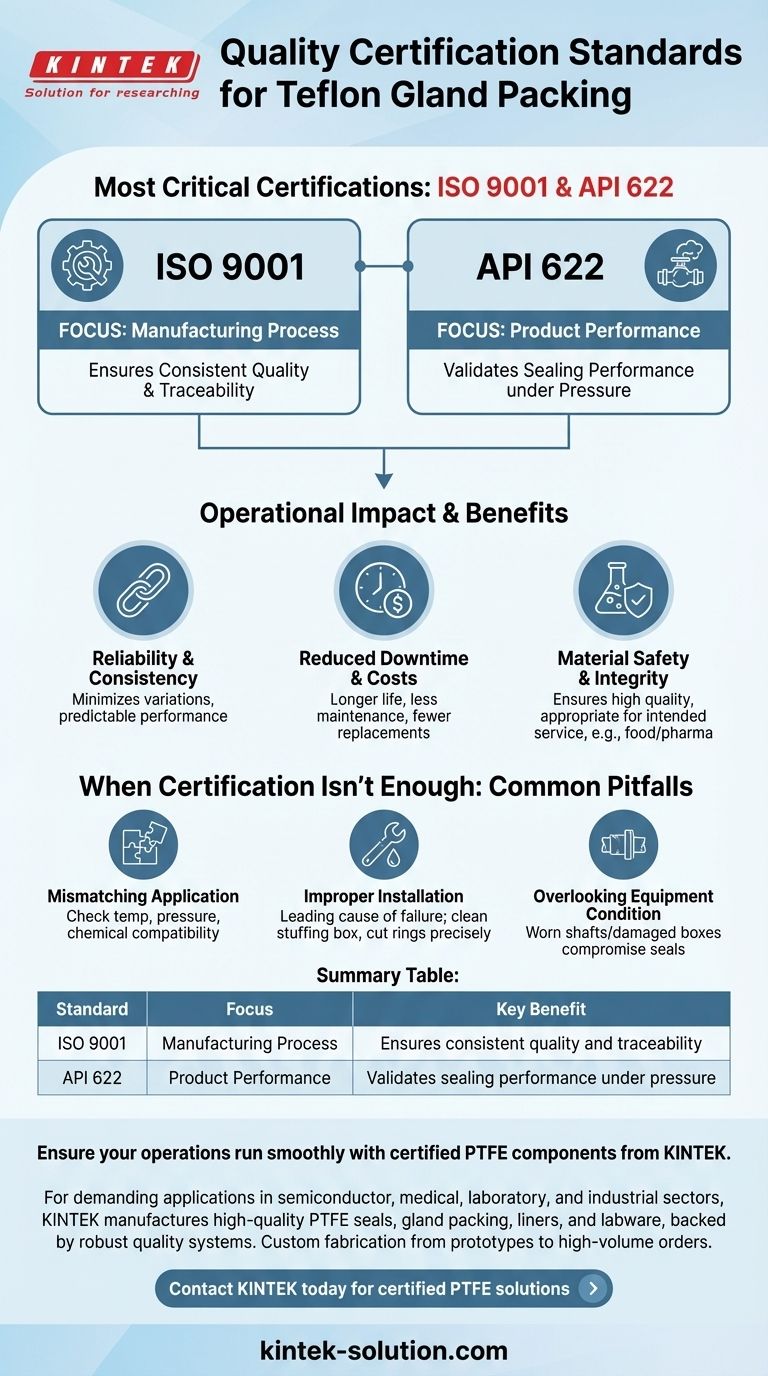

The most critical quality certifications for Teflon (PTFE) gland packing are ISO 9001 and API 622. These standards provide a framework for both manufacturing consistency and in-service performance. ISO 9001 ensures the manufacturer follows a documented quality management system, while API 622 provides a rigorous performance benchmark specifically for sealing materials used in critical applications.

While certifications like ISO 9001 and API 622 are essential markers of quality, they represent a baseline. True operational reliability is achieved only when a certified, high-quality product is correctly selected for the specific application and installed with precision.

Deconstructing the Key Quality Standards

Understanding what each standard certifies is crucial for making an informed decision. They address two different, but equally important, aspects of quality: the process of manufacturing and the performance of the final product.

ISO 9001: The Foundation of Quality Management

ISO 9001 is a globally recognized standard that focuses on the manufacturer's processes. It does not certify the product itself, but rather the system used to create it.

A manufacturer with ISO 9001 certification demonstrates a commitment to consistent production, traceability, and continuous improvement. This means you can expect a reliable and uniform product with every order.

API 622: The Benchmark for Sealing Performance

The American Petroleum Institute (API) 622 standard is a direct performance test for sealing materials, particularly those used in valves to control fugitive emissions.

Packing that meets API 622 has undergone rigorous testing for leakage control under specific thermal and pressure cycles. This certification provides objective proof of the packing's ability to maintain a reliable seal in demanding industrial environments.

Why These Standards Directly Impact Your Operations

Choosing packing that adheres to these standards is not just a matter of compliance; it has a direct and measurable impact on your facility's efficiency and bottom line.

Ensuring Product Reliability and Consistency

An ISO 9001 certified process minimizes variations between batches. This consistency is critical for predictable performance and reduces the risk of premature failure due to manufacturing defects.

Reducing Downtime and Maintenance Costs

High-performance packing, often validated by standards like API 622, lasts longer and requires less frequent adjustment. This translates directly to reduced labor costs, less downtime for equipment maintenance, and fewer packing replacements over the asset's lifecycle.

Guaranteeing Material Safety and Integrity

Reputable quality systems also ensure that the materials used, like the PTFE resin, are of high quality and appropriate for the intended service. For industries like food, beverage, or pharmaceuticals, this confirms the material is chemically inert and safe for contact.

Common Pitfalls: When Certification Isn't Enough

A certificate is a powerful tool, but it cannot overcome fundamental errors in selection or installation. The highest-rated packing will fail if it is not used correctly.

Mismatching the Packing to the Application

Always verify that the packing's specifications—including temperature, pressure, and chemical compatibility—are suitable for your specific operating conditions. A certified product used outside its design limits is destined for failure.

The Critical Role of Proper Installation

Improper installation is a leading cause of packing failure. Even the best packing will leak if the stuffing box is not thoroughly cleaned, the rings are not cut precisely, or the gland is over-tightened, which prevents proper lubrication and can damage the shaft.

Overlooking Equipment Condition

Worn shafts or damaged stuffing boxes can compromise the effectiveness of any packing. A quality seal requires equipment that is in good mechanical condition.

Making the Right Choice for Your Application

Use these standards as a guide to align your purchasing decisions with your operational priorities.

- If your primary focus is process consistency and traceability: Prioritize suppliers with a robust ISO 9001 certification to ensure repeatable manufacturing quality.

- If your primary focus is high-performance fugitive emissions control: Insist on packing that meets stringent standards like API 622 for proven sealing capability in critical valve applications.

- If your primary focus is operational longevity and reduced maintenance: Combine certified products with rigorous installation training and a thorough evaluation of your operating conditions.

Ultimately, using quality certifications as a starting point empowers you to select a product engineered for reliability.

Summary Table:

| Standard | Focus | Key Benefit |

|---|---|---|

| ISO 9001 | Manufacturing Process | Ensures consistent quality and traceability |

| API 622 | Product Performance | Validates sealing performance under pressure |

Ensure your operations run smoothly with certified PTFE components from KINTEK.

For demanding applications in the semiconductor, medical, laboratory, and industrial sectors, you need more than just a product—you need a guarantee of precision and reliability. KINTEK manufactures high-quality PTFE seals, gland packing, liners, and labware, backed by robust quality systems.

We offer custom fabrication from prototypes to high-volume orders, ensuring the perfect fit and performance for your specific needs. Don't let sealing failures cause downtime.

Contact KINTEK today to discuss your project and get a quote for reliable, certified PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry