In short, precision PTFE components are primarily manufactured using CNC machining processes like milling and turning. These subtractive methods are applied to pre-formed stock shapes—such as rods, blocks, or sheets—which are themselves created through molding or extrusion. This multi-step approach ensures the final part meets exacting dimensional tolerances.

The critical insight is that manufacturing a precision PTFE component is not a single event, but a controlled journey. It begins with creating a stable, semi-finished stock shape and concludes with high-precision CNC machining to achieve the final, intricate geometry.

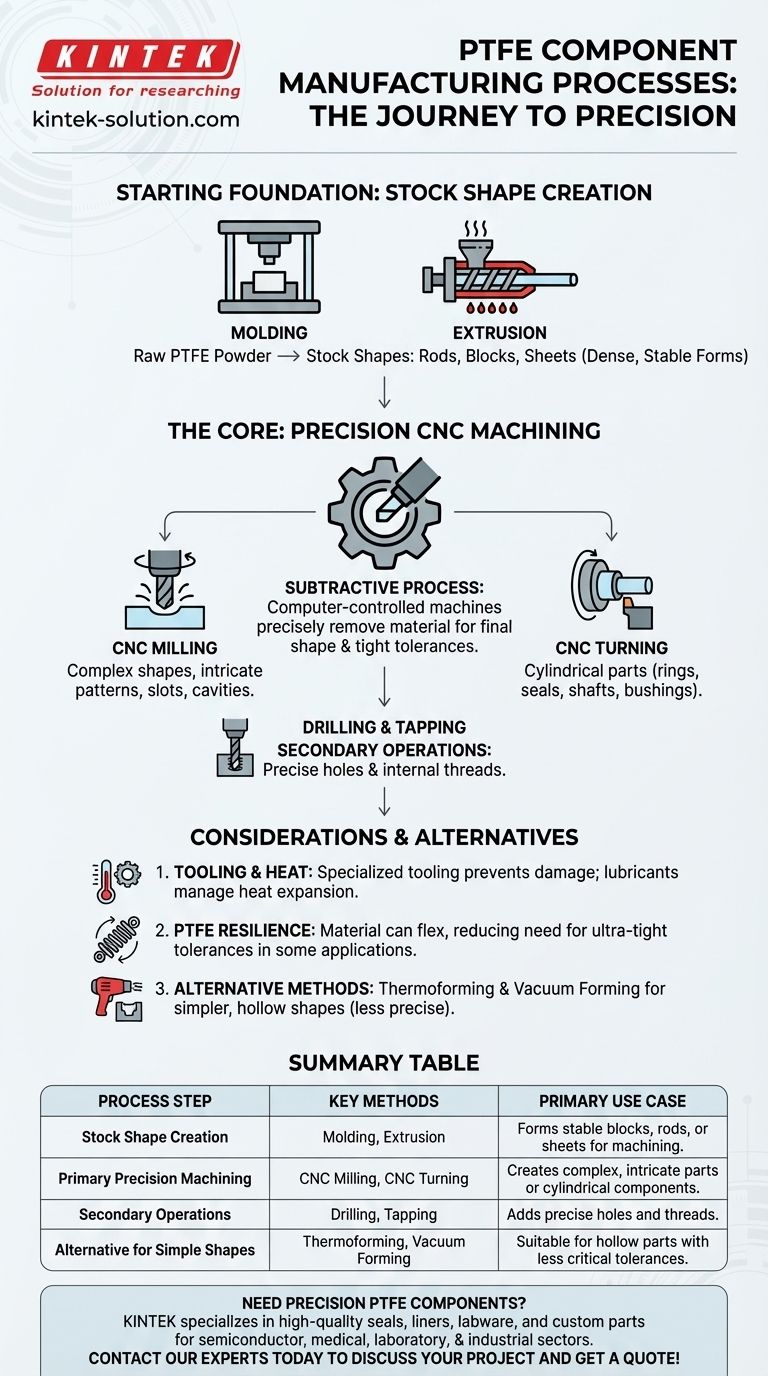

The Manufacturing Journey: From Raw Material to Precision Part

Understanding the full production lifecycle is key to appreciating how precision is achieved and controlled. The process is sequential, with each step building upon the last to ensure the final component's integrity and accuracy.

Starting with the Right Foundation: PTFE Stock Shapes

Production does not begin with raw PTFE powder. Instead, it starts with creating a solid, workable piece of material known as a "stock shape."

These standardized blocks, rods, and sheets are formed using two primary methods: molding or extrusion. This initial step converts the base PTFE compound into a dense, stable form that is ideal for subsequent machining operations.

The Core of Precision: CNC Machining

Once the stock shape is prepared, the actual work of creating a precision part begins. CNC (Computer Numerical Control) machining is a subtractive process where computer-controlled machines precisely remove material to create a final shape.

This method is the gold standard for PTFE components requiring tight tolerances because it offers unparalleled accuracy, repeatability, and the ability to create highly complex geometries.

Key Machining Techniques Explained

Within CNC machining, several specific techniques are used depending on the component's design.

- CNC Milling: This process uses rotating multi-point cutting tools to remove material from the workpiece. It is ideal for creating complex shapes, intricate patterns, slots, and cavities.

- CNC Turning: This involves rotating the PTFE workpiece while a stationary cutting tool removes material. It is the most effective method for producing cylindrical parts like rings, seals, shafts, and bushings.

- Drilling and Tapping: These are secondary operations used to create precise holes and internal threads within the component, often performed on the same CNC machines.

Understanding the Trade-offs and Considerations

While PTFE is known for being relatively easy to machine, achieving high precision consistently requires specific expertise and equipment. Ignoring these factors can lead to subpar results.

The Impact of Tooling and Heat

PTFE's characteristics demand specialized tooling designed for plastics to ensure clean cuts without damaging the material.

Furthermore, heat buildup during machining can cause the material to expand, compromising dimensional accuracy. The use of appropriate lubricants or coolants is often necessary to manage this thermal effect and maintain stability.

Leveraging PTFE's Natural Resilience

A unique property of PTFE is its resilience, or ability to conform under pressure. This is a significant advantage.

Because the material can flex slightly to fit its working environment, it is not always necessary to specify the absolute tightest tolerances. This understanding can prevent over-engineering and reduce manufacturing costs without sacrificing performance.

Alternative Methods: Thermoforming and Vacuum Forming

While methods like thermoforming (heating and molding a sheet) and vacuum forming exist, they are not the primary choice for high-precision components.

These processes are better suited for creating simpler, hollow shapes or parts with less critical dimensional requirements. For true precision, the accuracy of CNC machining remains unmatched.

Making the Right Choice for Your Component

Your component's specific design and functional requirements will determine the optimal manufacturing path.

- If your primary focus is intricate, non-symmetrical parts: Prioritize CNC milling, as it provides the design freedom and accuracy needed for complex geometries.

- If your primary focus is rotational or cylindrical components: Specify CNC turning for the most efficient and precise production of parts like seals, rings, and shafts.

- If your primary focus is high-volume production with moderate complexity: Consider a hybrid approach where molding creates a "near-net shape" that requires minimal finish machining, reducing waste and cost.

By understanding this complete manufacturing framework, you can specify the most effective and economical path to achieving your desired component performance.

Summary Table:

| Process Step | Key Methods | Primary Use Case |

|---|---|---|

| Stock Shape Creation | Molding, Extrusion | Forms stable blocks, rods, or sheets for machining. |

| Primary Precision Machining | CNC Milling, CNC Turning | Creates complex, intricate parts or cylindrical components. |

| Secondary Operations | Drilling, Tapping | Adds precise holes and threads. |

| Alternative for Simple Shapes | Thermoforming, Vacuum Forming | Suitable for hollow parts with less critical tolerances. |

Need precision PTFE components for your application?

At KINTEK, we specialize in manufacturing high-quality PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in CNC machining ensures your parts meet the most demanding tolerances and specifications, from prototypes to high-volume production.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications