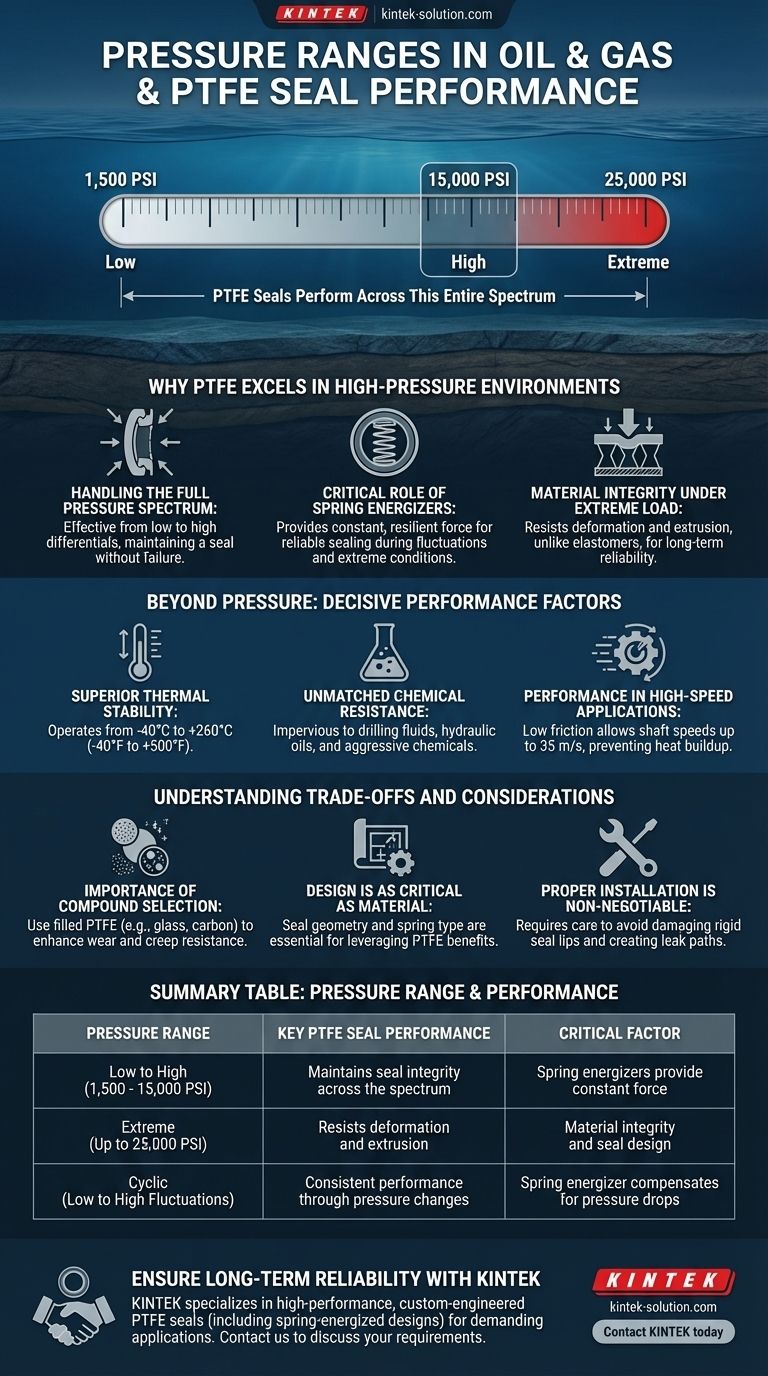

In the oil and gas industry, operating pressures commonly range from 1,500 psi to 15,000 psi, with extreme applications reaching as high as 25,000 psi. PTFE (Polytetrafluoroethylene) seals are exceptionally well-suited for this entire spectrum, performing reliably at both low and high pressures, particularly when engineered with features like spring energizers to ensure constant sealing force.

The true value of PTFE seals in oil and gas is not just their ability to handle extreme pressures, but their unique resilience to the combined challenges of high speeds, wide temperature swings, and corrosive chemicals, ensuring long-term sealing integrity where other materials would fail.

Why PTFE Excels in High-Pressure Environments

The suitability of PTFE for oil and gas applications goes far beyond a simple pressure rating. It stems from the material's inherent properties and the sophisticated design of the seals themselves.

Handling the Full Pressure Spectrum

PTFE seals are effective across the vast range of pressures found in the industry. This versatility means they can maintain a seal in low-pressure states and withstand the immense forces of high-pressure differentials without failing.

The Critical Role of Spring Energizers

In many advanced PTFE seals, a metallic spring energizer is incorporated into the seal jacket. This spring provides a constant, resilient mechanical force that pushes the seal lips against the hardware. This is crucial for maintaining a tight seal during low-pressure periods, pressure fluctuations, and in extreme high-pressure conditions where material integrity is paramount.

Material Integrity Under Extreme Load

Unlike some elastomers that can deform or extrude through gaps under high pressure, high-quality PTFE grades maintain their structural integrity. This resistance to deformation is essential for long-term, reliable sealing in valves, pumps, and downhole logging tools.

Beyond Pressure: Other Decisive Performance Factors

Pressure is only one piece of the puzzle. Oil and gas environments are a combination of harsh conditions, and PTFE’s multi-faceted resilience is what makes it a superior choice.

Superior Thermal Stability

PTFE seals operate effectively across wide temperature swings, from -40°C to over 177°C (-40°F to 350°F), with some able to withstand up to 260°C (500°F). This stability is critical in applications from surface equipment to downhole tools where temperatures fluctuate dramatically.

Unmatched Chemical Resistance

The material is nearly impervious to corrosive drilling fluids, hydraulic oils, and other aggressive chemicals common in the industry. This chemical inertness prevents material degradation and ensures an unlimited shelf life, providing a significant advantage over many standard elastomers.

Performance in High-Speed Applications

PTFE has one of the lowest coefficients of friction of any solid material. This allows it to handle very high shaft surface speeds—up to 35 m/s—without generating excessive heat. This property is vital for preventing premature seal failure in high-speed rotating equipment like pumps and turbochargers.

Understanding the Trade-offs and Considerations

While highly effective, achieving optimal performance with PTFE seals requires a clear understanding of the material and its application.

The Importance of Compound Selection

"PTFE" is a family of materials. Pure PTFE can be susceptible to "cold flow" or creep under sustained load. High-performance applications often use filled PTFE grades (e.g., with glass, carbon, or other polymers) to enhance wear resistance and rigidity under high pressure and temperature.

Design is as Critical as Material

The performance of a seal is a function of its design, not just the raw material. The geometry of the seal lips, the type of spring energizer used, and the gland design all play a crucial role in its success. A well-engineered seal design is essential to leverage PTFE's benefits fully.

Proper Installation is Non-Negotiable

PTFE seals can be more rigid than their elastomeric counterparts. Careful installation is required to avoid scratching or damaging the seal lips, as any imperfection can create a leak path, especially in a high-pressure system.

Making the Right Choice for Your Application

Selecting the correct sealing solution depends on identifying the most critical challenge in your specific operating environment.

- If your primary focus is extreme high pressure (15,000+ psi): Prioritize a spring-energized PTFE seal, as the spring ensures a consistent sealing force that compensates for any minor material relaxation under load.

- If your application involves high rotational speeds: Select a PTFE grade with a low coefficient of friction to minimize heat generation and prevent premature wear.

- If you are dealing with corrosive fluids or wide temperature swings: The inherent chemical inertness and thermal stability of PTFE make it a fundamentally safer and more reliable choice than most elastomers.

- If your system experiences frequent pressure cycles from low to high: A spring-energized seal is critical to maintain sealing integrity, as the spring provides the necessary force when system pressure is too low to fully actuate the seal.

Ultimately, choosing the right PTFE seal is an investment in operational reliability across a wide range of demanding conditions.

Summary Table:

| Pressure Range | Key PTFE Seal Performance | Critical Factor |

|---|---|---|

| Low to High (1,500 - 15,000 PSI) | Maintains seal integrity across the spectrum | Spring energizers provide constant force |

| Extreme (Up to 25,000 PSI) | Resists deformation and extrusion | Material integrity and seal design |

| Cyclic (Low to High Fluctuations) | Consistent performance through pressure changes | Spring energizer compensates for pressure drops |

Ensure long-term reliability in your most demanding oil and gas applications.

KINTEK specializes in manufacturing high-performance PTFE seals and components, including spring-energized designs, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution precisely engineered for your specific pressure, temperature, and chemical challenges.

Contact KINTEK today to discuss your application requirements and leverage our precision production capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications