Beyond their well-known use in chemical plants, PTFE gaskets are critical components in a surprisingly diverse range of fields, including electrical insulation, wiring system sealing, and dynamic mechanical systems. Their utility extends far beyond static pipe flanges, playing a crucial role in applications that require low friction, high purity, or the sealing of sensitive, brittle materials.

The immense versatility of PTFE gaskets is not due to one single feature, but to a rare combination of properties: extreme chemical inertness, a vast operational temperature range, a very low coefficient of friction, and excellent electrical insulation. Understanding these core attributes is the key to identifying their ideal use cases.

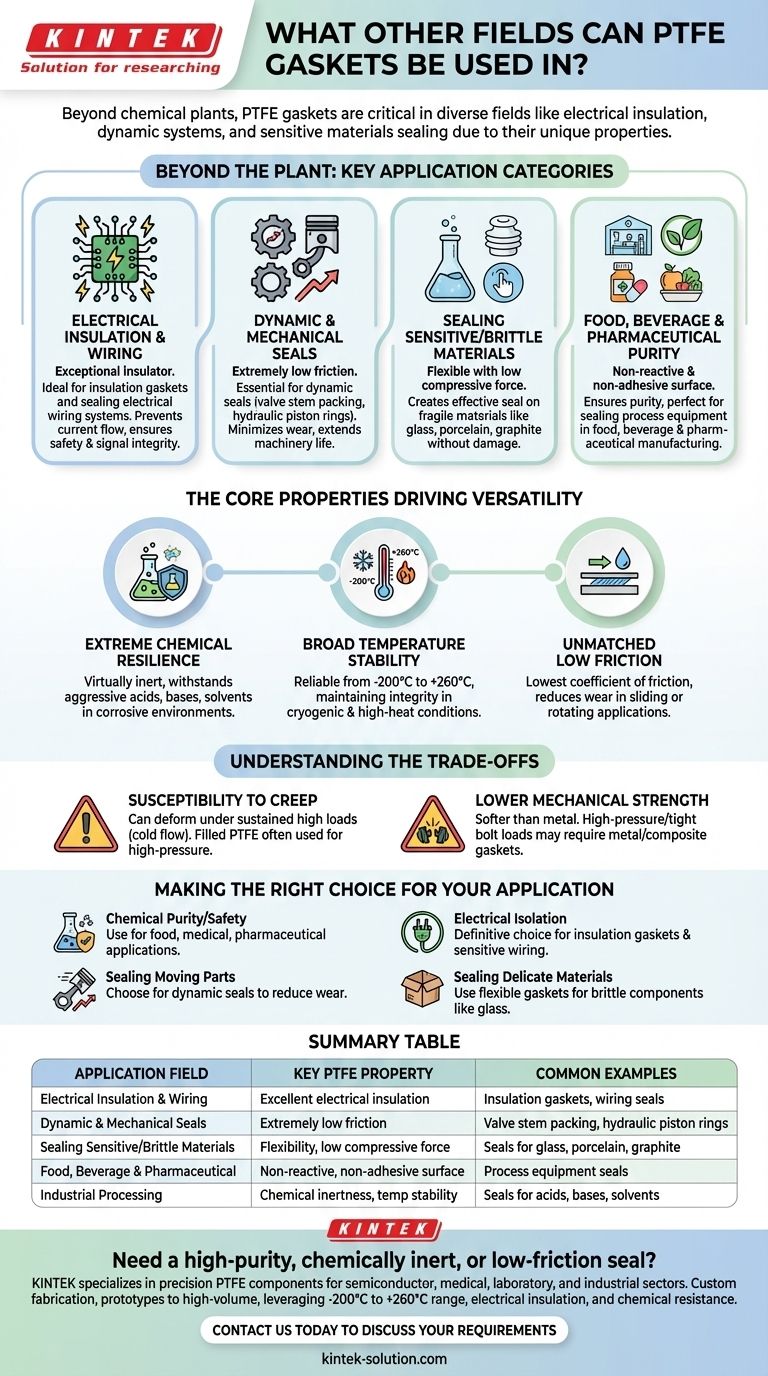

Beyond the Plant: Key Application Categories

While industrial processing is a primary use, the unique characteristics of PTFE open up applications in several other critical engineering domains.

Electrical Insulation and Wiring

PTFE is an exceptional electrical insulator. This property makes it the ideal material for insulation gaskets and for sealing electrical wiring systems.

It prevents the flow of current between conductive components, ensuring both safety and signal integrity in sensitive electronic and electrical equipment.

Dynamic and Mechanical Seals

The extremely low coefficient of friction of PTFE is a significant advantage. This "slipperiness" is essential for dynamic seals where parts move against each other.

Applications include valve stem packing and hydraulic piston rings, where PTFE ensures a tight seal while minimizing wear and tear, which extends the life of the machinery.

Sealing for Sensitive and Brittle Materials

PTFE gaskets are flexible and can create a highly effective seal with relatively low compressive force. This is critical when working with fragile materials.

They are used to seal connections on components made of glass, porcelain, graphite, and certain plastics, preventing leaks without risking damage to the brittle flange surfaces.

Food, Beverage, and Pharmaceutical Purity

In industries where purity is non-negotiable, PTFE is a first-choice material. Its non-reactive and non-adhesive surface does not contaminate the process media.

This makes it perfect for sealing equipment in food and beverage manufacturing and pharmaceutical applications, where cleanliness and preventing chemical reactions are paramount.

The Core Properties Driving Versatility

The suitability of PTFE for such varied applications stems directly from a few fundamental material properties that are rarely found together in one material.

Extreme Chemical Resilience

PTFE gaskets are virtually inert and do not react with most chemicals, including aggressive acids, bases, and solvents. This makes them exceptionally durable in corrosive environments found in chemical and petrochemical plants.

Broad Temperature Stability

These gaskets perform reliably across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to +500°F). They maintain their integrity and sealing capability in both cryogenic and high-heat conditions.

Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This property is what makes it ideal for sliding or rotating applications, as it reduces friction and mechanical wear between moving parts.

Understanding the Trade-offs

While incredibly versatile, PTFE is not the universal solution for every sealing challenge. Understanding its limitations is key to successful application.

Susceptibility to Creep

Under sustained, high compressive loads, standard PTFE can be prone to "creep" or cold flow, where the material slowly deforms over time. This can lead to a loss of sealing pressure. For high-pressure applications, filled PTFE variants are often used to mitigate this effect.

Lower Mechanical Strength

Compared to metallic gaskets, PTFE is a softer material. In applications with extremely high pressures and tight bolt loads, a metal or composite gasket might be required to withstand the mechanical forces without being extruded from the flange.

Making the Right Choice for Your Application

To leverage PTFE effectively, match its strengths to your primary engineering goal.

- If your primary focus is chemical purity and safety: Use PTFE gaskets for food, medical, or pharmaceutical applications where its inert, non-stick surface is essential.

- If your primary focus is sealing moving parts: Choose PTFE for dynamic seals like valve stems or pistons where its low friction reduces wear and ensures smooth operation.

- If your primary focus is electrical isolation: PTFE is the definitive choice for insulation gaskets and for sealing enclosures in sensitive wiring systems.

- If your primary focus is sealing delicate materials: Use flexible PTFE gaskets to create a reliable seal on brittle components like glass or graphite without the risk of fracture.

By understanding these core properties, you can confidently identify where PTFE is not just an option, but the optimal engineering solution for your challenge.

Summary Table:

| Application Field | Key PTFE Property Utilized | Common Examples |

|---|---|---|

| Electrical Insulation & Wiring | Excellent electrical insulation | Insulation gaskets, wiring system seals |

| Dynamic & Mechanical Seals | Extremely low coefficient of friction | Valve stem packing, hydraulic piston rings |

| Sealing Sensitive/Brittle Materials | Flexibility, low compressive force | Seals for glass, porcelain, graphite components |

| Food, Beverage & Pharmaceutical | Non-reactive, non-adhesive surface | Process equipment seals ensuring purity |

| Industrial Processing | Chemical inertness, temperature stability | Seals for acids, bases, solvents in harsh environments |

Need a high-purity, chemically inert, or low-friction seal for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, gaskets, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our custom fabrication ensures a perfect fit for your unique needs, leveraging PTFE's broad temperature range (-200°C to +260°C), excellent electrical insulation, and unmatched chemical resistance.

Contact us today to discuss your specific requirements and let our experts provide a sealing solution that enhances safety, efficiency, and reliability in your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments