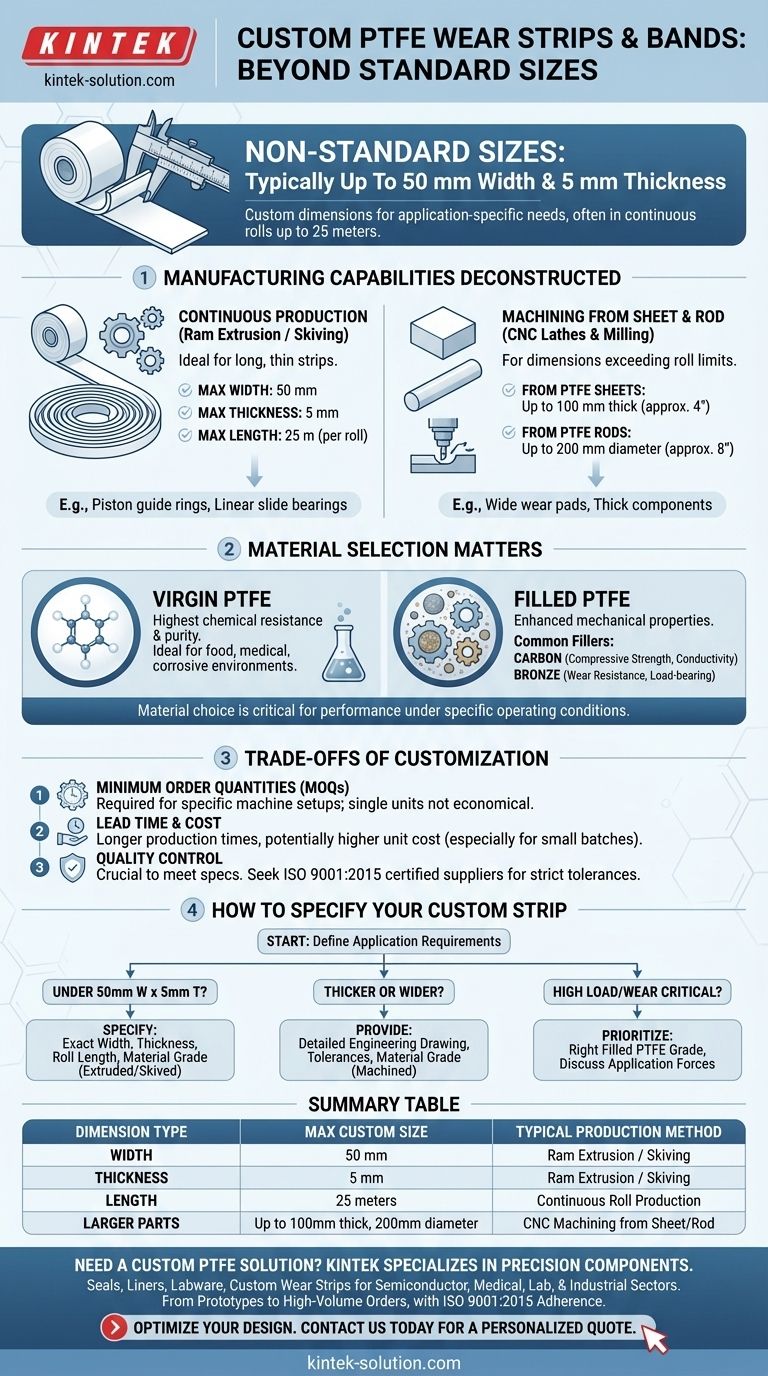

In short, non-standard PTFE wear strips and bands can typically be manufactured up to 50 mm in width and up to 5 mm in thickness. These custom-dimensioned strips are often available in continuous roll lengths of up to 25 meters, allowing for precise, application-specific sizing beyond standard off-the-shelf options.

While standard sizes offer convenience, your specific design often demands a custom solution. The key is understanding that modern manufacturing can produce PTFE wear strips with precise, non-standard dimensions, but this flexibility is governed by the production method, material grade, and the scale of your order.

Deconstructing Manufacturing Capabilities

To understand what is possible, you must first understand how these components are made. The dimensions you can specify are a direct result of the manufacturing process used.

The Boundaries of Continuous Production

Most wear strips are produced through processes like ram extrusion or skiving from a larger billet. This method is highly efficient for creating long, continuous lengths.

For these processes, the typical dimensional limits are:

- Maximum Width: 50 mm

- Maximum Thickness: 5 mm

- Maximum Length: 25 meters (in a single roll)

This method is ideal when you need a long, thin, and relatively narrow strip for applications like piston guide rings or linear slide bearings.

Beyond the Roll: Machining from Sheet and Rod

If your design requires dimensions that exceed the limits of continuous production, the component must be machined from larger stock material.

Manufacturers use CNC lathes and milling machines to cut custom parts from:

- PTFE Sheets: Available in sizes like 1200x1200 mm and thicknesses up to 4 inches (approx. 100 mm).

- PTFE Rods: Available with outside diameters up to 8 inches (approx. 200 mm).

This means if you need a wear pad that is 100 mm wide or 10 mm thick, it will not be skived from a roll but rather precision-cut from a sheet of PTFE.

Material Selection for Your Custom Part

The material grade you choose is as important as the dimensions. The right choice ensures the part performs correctly under its specific operating conditions.

Virgin vs. Filled PTFE

Manufacturers offer several grades of PTFE, each with distinct properties.

- Virgin PTFE: Offers the highest chemical resistance and purity, making it ideal for food, medical, or highly corrosive environments.

- Filled PTFE: Virgin PTFE is blended with additives to enhance specific mechanical properties. Common fillers include carbon (for improved compressive strength and conductivity) and bronze (for significantly increased wear resistance and load-bearing capacity).

Why Material Choice Matters

Your application dictates the material. A high-load hydraulic cylinder guide ring requires a bronze-filled PTFE for durability, whereas a component in a chemical processing plant may demand the inertness of virgin PTFE. Always specify the material grade along with the dimensions.

Understanding the Trade-offs of Customization

Requesting a non-standard size introduces a new set of considerations compared to buying a standard part. Being aware of these trade-offs is crucial for project planning.

Minimum Order Quantities (MOQs)

Custom manufacturing runs require specific machine setups and tooling adjustments. Because of this initial effort, suppliers will almost always require a minimum order quantity (MOQ). It is generally not economical to produce a single, one-off custom strip.

Lead Time and Cost

Custom parts are made to order and are not sitting in inventory. You must account for longer lead times for production and delivery. The cost per unit may also be higher than for standard sizes, especially for smaller batches.

The Critical Role of Quality Control

When you order a custom part, you are relying on the manufacturer to meet your exact specifications. Look for suppliers with a robust quality management system, such as an ISO 9001:2015 certification. This ensures that strict tolerances on thickness and width are maintained from raw material input to the final product.

How to Specify Your Custom Wear Strip

Use your application's requirements to guide your specification process.

- If your design fits within roll parameters (under 50mm width and 5mm thickness): Focus on specifying the exact width, thickness, roll length, and material grade needed for your extruded or skived part.

- If you need a thicker or wider component: Your part will be machined from a sheet or block. Provide the manufacturer with a detailed engineering drawing showing all final dimensions, tolerances, and the required material grade.

- If performance under high load or wear is critical: Prioritize selecting the right filled PTFE grade (e.g., carbon-filled or bronze-filled) and be prepared to discuss the specific application forces and environment with the manufacturer.

Armed with this understanding of the manufacturing process, you can confidently specify a custom solution that meets your exact engineering requirements.

Summary Table:

| Dimension Type | Maximum Custom Size | Typical Production Method |

|---|---|---|

| Width | 50 mm | Ram Extrusion / Skiving |

| Thickness | 5 mm | Ram Extrusion / Skiving |

| Length | 25 meters | Continuous Roll Production |

| Larger Parts | Up to 100mm thick, 200mm diameter | CNC Machining from Sheet/Rod |

Need a custom PTFE wear strip or band for your application?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, labware, and custom wear strips—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, we deliver tailored solutions with strict adherence to your specifications and ISO 9001:2015 quality standards.

Let us help you optimize your design with the right material and dimensions. Contact us today to discuss your project requirements and receive a personalized quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application