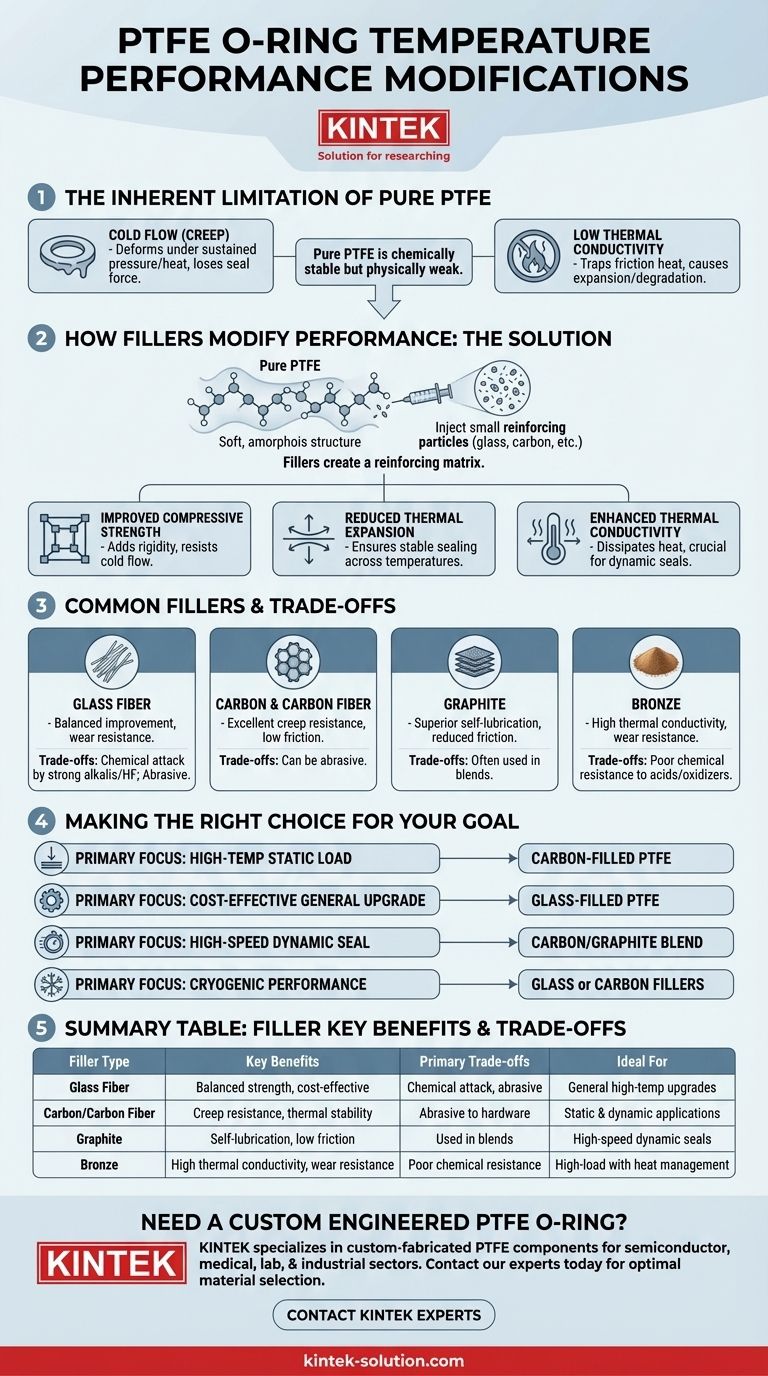

To enhance their temperature performance, standard PTFE O-rings are modified by adding reinforcing fillers. Materials like glass fiber and carbon are compounded with the virgin PTFE resin to create specialized variants that overcome the physical weaknesses of the base polymer, especially under extreme thermal conditions.

The core challenge with pure PTFE is not its chemical stability at temperature, but its physical weakness. It is prone to cold flow and deformation under load. Modifications don't change the fundamental chemistry; they add a structural skeleton to the material, drastically improving its mechanical integrity from cryogenic lows to elevated highs.

The Inherent Limitation of Pure PTFE

Pure, or "virgin," PTFE is renowned for its incredible chemical inertness and wide service temperature range. However, its mechanical properties present significant challenges in demanding sealing applications.

The Problem of Cold Flow (Creep)

The primary weakness of virgin PTFE is cold flow, also known as creep.

Under sustained pressure, even at room temperature, the material will slowly and permanently deform, causing a seal to lose its compressive force and eventually fail.

This effect is significantly accelerated at elevated temperatures, making it a critical failure mode for high-temperature seals.

Low Thermal Conductivity

PTFE is an excellent thermal insulator. In dynamic sealing applications, this means friction-generated heat is not easily dissipated.

This trapped heat can cause the seal to expand excessively or degrade, leading to premature failure.

How Fillers Modify Performance

Adding fillers to PTFE creates a composite material. These fillers act as a reinforcing matrix, fundamentally changing the physical behavior of the polymer.

Improving Compressive Strength

Fillers like glass and carbon add rigidity and structure to the soft PTFE polymer.

This drastically increases the material's resistance to deformation under load, directly combating the primary issue of cold flow.

Reducing Thermal Expansion

Fillers have a much lower coefficient of thermal expansion than pure PTFE.

By incorporating them, the overall expansion and contraction of the O-ring is reduced, ensuring a more stable and predictable seal across a wide temperature range.

Enhancing Thermal Conductivity

Certain fillers, especially carbon and bronze, significantly improve the thermal conductivity of the composite.

This allows heat to be drawn away from the sealing interface, which is critical for managing friction and preventing thermal degradation in high-speed or high-pressure dynamic seals.

Common Fillers and Their Trade-offs

Choosing a filler involves balancing performance gains with potential downsides. No single filler is universally superior; the choice is application-dependent.

Glass Fiber

This is a common, general-purpose filler that provides a balanced improvement in compressive strength and wear resistance.

However, glass can be attacked by strong alkalis and hydrofluoric acid, reducing the chemical compatibility. It can also be abrasive to softer metal hardware.

Carbon & Carbon Fiber

Carbon offers excellent compressive strength, load resistance, and low friction. It is often combined with graphite.

Carbon-filled compounds provide superb high-temperature performance and good thermal conductivity. They are generally more chemically resistant than glass-filled variants but can be abrasive.

Graphite

Graphite is primarily used to reduce friction and improve self-lubricating properties, making it ideal for dynamic seals.

When blended with carbon, it creates a high-performance material with excellent wear resistance and thermal stability.

Bronze

Bronze provides excellent wear resistance and high thermal conductivity, making it suitable for applications with high mechanical loads.

Its primary trade-off is significantly reduced chemical resistance. Bronze-filled PTFE should not be used with strong acids or oxidizing agents.

Making the Right Choice for Your Goal

Your operational environment dictates the ideal modification. Analyze your primary challenge to select the most effective material.

- If your primary focus is high-temperature stability under static load: Carbon-filled PTFE offers the best resistance to creep and deformation.

- If your primary focus is a cost-effective, general-purpose upgrade: Glass-filled PTFE provides a balanced enhancement of mechanical properties for a wide range of applications.

- If your primary focus is a high-speed dynamic seal: A carbon/graphite blend provides the necessary self-lubrication and thermal conductivity to manage friction.

- If your primary focus is cryogenic performance: Both glass and carbon fillers are effective, as their main role is to reduce thermal contraction and maintain seal integrity at extreme lows.

By understanding these modifications, you can move beyond a standard material and specify a seal engineered precisely for your application's demands.

Summary Table:

| Filler Type | Key Benefits | Primary Trade-offs | Ideal For |

|---|---|---|---|

| Glass Fiber | Balanced compressive strength, cost-effective | Reduced chemical resistance to strong alkalis/HF; can be abrasive | General-purpose high-temperature upgrades |

| Carbon/Carbon Fiber | Excellent creep resistance, high thermal stability, low friction | Can be abrasive to hardware | High-temperature static seals, dynamic applications |

| Graphite | Superior self-lubrication, reduced friction | Often used in blends for optimal performance | High-speed dynamic seals |

| Bronze | High thermal conductivity, excellent wear resistance | Poor chemical resistance to acids/oxidizers | High-load applications with thermal management needs |

Need a PTFE O-ring engineered for your specific temperature and pressure challenges?

At KINTEK, we specialize in custom-fabricated PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our precision manufacturing ensures optimal material selection (like carbon-filled or glass-filled PTFE) to combat cold flow, enhance thermal stability, and extend seal life in your application.

Contact our experts today for a tailored solution that meets your exact performance requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support