In the medical field, Polytetrafluoroethylene (PTFE) is a highly valued material used for a range of critical applications, from permanent implants like artificial blood vessels and heart patches to essential devices like catheters and surgical instruments. Its widespread adoption is due to a unique combination of properties, primarily its exceptional biocompatibility, chemical inertness, and low-friction surface.

The core reason for PTFE's medical success is not a single feature, but its powerful synergy of properties. It is one of the few materials that is almost completely ignored by the human body, resists chemical breakdown, and provides a non-stick surface that helps prevent complications like infection.

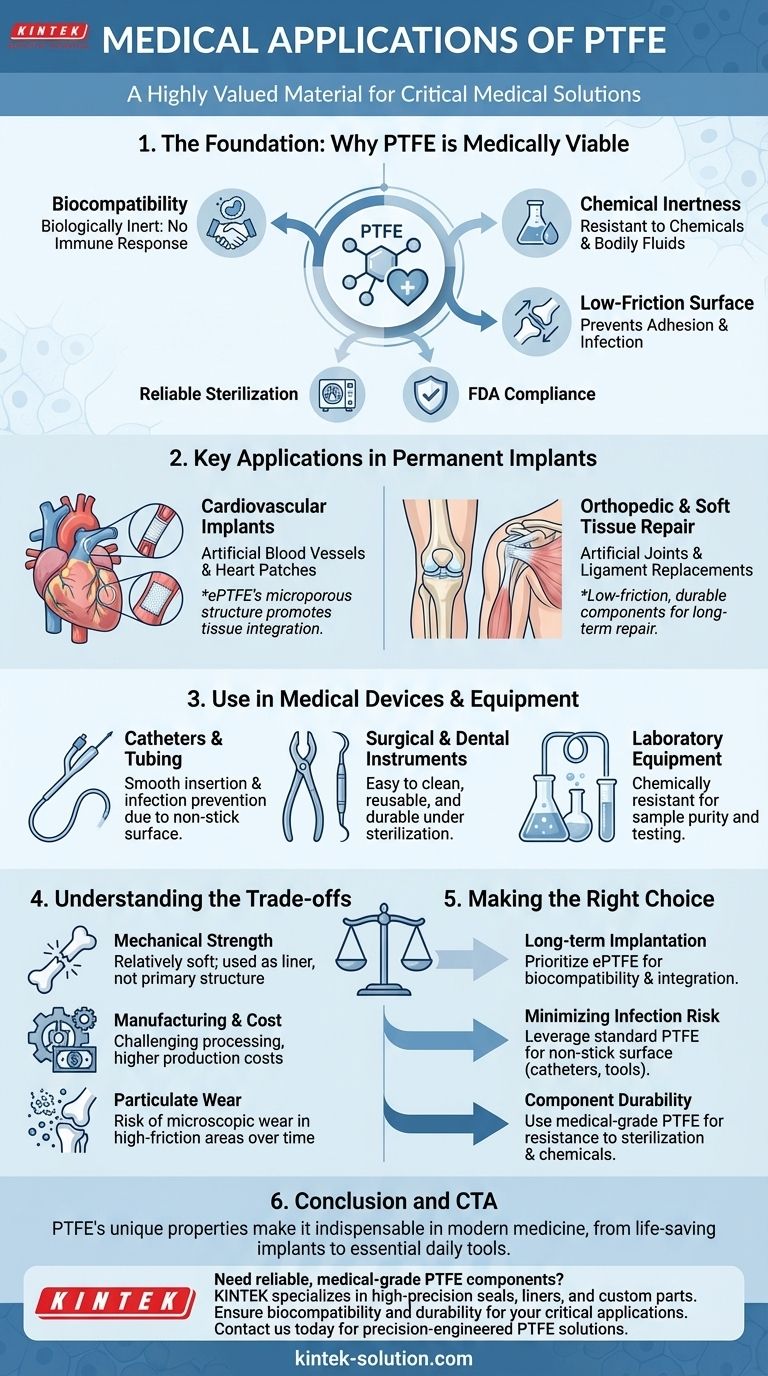

The Foundation: Why PTFE is Medically Viable

The suitability of any material for medical use depends on its ability to perform its function without harming the patient. PTFE excels in these foundational requirements.

Unmatched Biocompatibility

PTFE is biologically inert. This means the human body's immune system does not recognize it as a foreign invader, which prevents inflammation, rejection, and other adverse physiological side effects.

Absolute Chemical Inertness

The material is non-reactive and highly resistant to chemicals. This ensures it will not degrade when exposed to bodily fluids or administered medications, maintaining its structural integrity over long periods.

Reliable Sterilization

A critical requirement for any medical device is the ability to be sterilized. PTFE can withstand all common sterilization methods without degrading, ensuring patient safety.

FDA Regulatory Compliance

Medical-grade PTFE is manufactured to meet the strict standards set by regulatory bodies like the U.S. Food and Drug Administration (FDA), confirming its safety and efficacy for clinical use.

Key Applications in Medical Implants

PTFE is frequently the material of choice for devices intended to remain inside the body, where safety and long-term stability are paramount.

Cardiovascular Grafts and Patches

Expanded PTFE (ePTFE) features a multi-microporous structure that is ideal for creating artificial blood vessels. This structure allows the body's own cells to grow into the material, improving integration and long-term performance. It is also used for heart patches and surgical sutures in cardiac procedures.

Orthopedic and Soft Tissue Repair

Due to its low-friction properties and durability, PTFE is used in components for artificial joints. It is also a trusted material for ligament replacements and soft tissue regeneration patches, helping to repair and reinforce damaged areas in general and plastic surgeries.

Use in Medical Devices and Equipment

Beyond permanent implants, PTFE's properties make it invaluable for tools and devices used in daily clinical practice.

Catheters and Tubing

PTFE's exceptionally low-friction, non-stick surface is crucial for catheters. This property not only ensures smoother insertion but also helps prevent the adhesion and growth of bacteria, a major source of hospital-acquired infections.

Surgical and Dental Instruments

The material is used in various surgical and dental tools. Its non-stick nature is beneficial in applications where cleanliness is critical, and its durability ensures a long service life despite repeated use and sterilization.

Laboratory and Testing Equipment

Because it doesn't react with corrosive chemicals, PTFE is widely used for containers, tubing, and pipework in medical testing and research laboratories where sample purity is essential.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. Understanding its limitations is key to its proper application.

Mechanical Strength

PTFE is a relatively soft polymer compared to metals like titanium. In high-load-bearing applications, such as the primary structure of an artificial hip, it is typically used as a low-friction liner rather than the main structural component.

Manufacturing and Cost

Processing PTFE into complex shapes can be more challenging and expensive than with other common polymers, which can influence the cost and design of medical devices.

Risk of Particulate Wear

In very high-friction applications like joint replacements, there is a long-term risk that microscopic particles can wear off the surface. While PTFE is inert, an accumulation of these particles over decades can potentially trigger a foreign-body response from the immune system.

Making the Right Choice for Your Goal

The decision to use PTFE should be driven by the specific demands of the medical application.

- If your primary focus is long-term implantation: Prioritize expanded PTFE (ePTFE) for its excellent biocompatibility and porous structure that encourages tissue integration.

- If your primary focus is minimizing infection risk in devices: Leverage standard PTFE's non-stick, low-friction surface for applications like catheters and reusable surgical tools.

- If your primary focus is component durability and chemical resistance: Use medical-grade PTFE for instruments and equipment that must withstand aggressive sterilization and chemical exposure.

Ultimately, PTFE's unique combination of biological inertness and high-performance physical properties makes it an indispensable material in the advancement of modern medicine.

Summary Table:

| Application Category | Key PTFE Properties | Examples |

|---|---|---|

| Permanent Implants | Biocompatibility, Porous Structure (ePTFE) | Vascular grafts, heart patches, ligament replacements |

| Medical Devices | Low Friction, Non-stick, Chemical Inertness | Catheters, surgical instruments, tubing |

| Lab Equipment | Chemical Resistance, Durability | Labware, containers, pipework for testing |

Need reliable, medical-grade PTFE components for your next project? KINTEK specializes in manufacturing high-precision PTFE seals, liners, labware, and custom parts for the semiconductor, medical, and laboratory industries. Our expertise ensures biocompatibility, chemical resistance, and durability for your most critical applications, from prototypes to high-volume production. Contact us today to discuss how we can support your medical device innovation with precision-engineered PTFE solutions.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers