In the medical field, material selection directly impacts patient safety, and Polytetrafluoroethylene (PTFE) is a cornerstone material for this reason. Its exceptional biocompatibility—meaning it is non-toxic and does not cause adverse reactions in the human body—makes it essential for critical applications like implantable vascular grafts, catheters, surgical instruments, and liners for various diagnostic tools.

The core reason PTFE is trusted in medicine is its chemical inertness. This property ensures that devices made from PTFE will not react with sensitive tissues or bodily fluids, minimizing the risk of rejection or complications and enabling safer, more effective medical interventions.

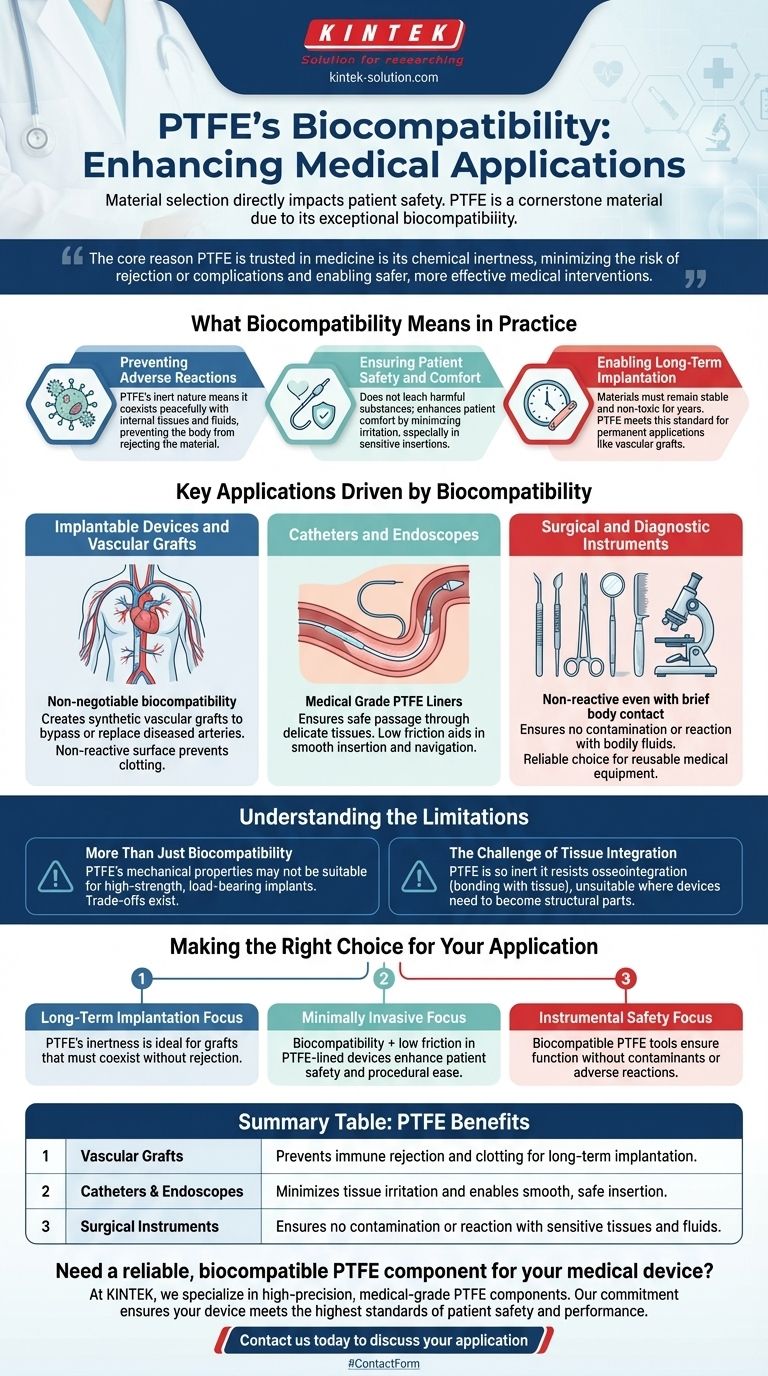

What "Biocompatibility" Means in Practice

Biocompatibility is not just an abstract scientific term; it is a fundamental requirement for any material that will make contact with the human body. It represents a promise of safety and stability.

Preventing Adverse Reactions

A material is considered biocompatible when it does not trigger an immune response or other harmful reactions. PTFE's inert nature means it coexists peacefully with internal tissues and fluids.

This prevents the body from rejecting the material, which is critical for any device intended for internal use, from temporary insertion to permanent implantation.

Ensuring Patient Safety and Comfort

Because PTFE does not leach harmful substances or degrade into toxic by-products, it ensures patient safety over the device's entire lifecycle.

For devices like catheters that are inserted into sensitive areas, this non-reactivity also translates directly to enhanced patient comfort by minimizing irritation.

Enabling Long-Term Implantation

The ultimate test of biocompatibility is in long-term implants. Materials must remain stable and non-toxic for years or even decades.

PTFE meets this standard, which is why it is a preferred material for applications like vascular grafts that become a permanent part of the patient's body.

Key Applications Driven by Biocompatibility

PTFE's unique properties make it suitable for a wide range of medical devices where direct tissue contact is a primary concern.

Implantable Devices and Vascular Grafts

For devices that remain inside the body, biocompatibility is non-negotiable. PTFE is used to create synthetic vascular grafts to bypass or replace diseased arteries.

Its non-reactive surface allows blood to flow without clotting and prevents the surrounding tissue from launching an immune attack against the implant.

Catheters and Endoscopes

Many minimally invasive procedures rely on catheters and endoscopes to navigate inside the body. These devices are often constructed with Medical Grade PTFE Liners.

The biocompatibility of the liner ensures it can safely pass through delicate tissues, while PTFE's characteristic low friction also aids in smooth insertion and navigation.

Surgical and Diagnostic Instruments

Even tools with brief body contact must be non-reactive. PTFE is used in a variety of surgical and diagnostic instruments to ensure they do not contaminate tissue or react with bodily fluids during a procedure.

This property, combined with its ability to withstand sterilization, makes it a reliable choice for reusable medical equipment.

Understanding the Limitations

While PTFE's biocompatibility is a significant advantage, it is essential to see it as one part of a larger set of material properties. No single material is perfect for every application.

More Than Just Biocompatibility

Material selection always involves trade-offs. While PTFE is exceptionally inert and has low friction, its mechanical properties may not be suitable for high-strength, load-bearing implants like artificial joints.

Engineers must also consider factors like sterilizability, flexibility, and manufacturing costs alongside biocompatibility when designing a medical device.

The Challenge of Tissue Integration

In some medical applications, the goal is for an implant to actively bond with the surrounding tissue—a process called osseointegration.

Because PTFE is so inert and non-stick, it resists integration. While this is an advantage for preventing unwanted adhesion, it makes PTFE unsuitable for applications where the device needs to become a structural part of the body's own tissue.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with the primary goal of the medical device. PTFE's biocompatibility makes it a clear choice for specific, critical functions.

- If your primary focus is long-term implantation: PTFE's proven inertness makes it ideal for devices like vascular grafts that must coexist with tissue without causing rejection.

- If your primary focus is minimally invasive procedures: The combination of biocompatibility and low friction in PTFE-lined catheters and endoscopes is critical for enhancing patient safety and procedural ease.

- If your primary focus is instrumental safety: Using biocompatible PTFE in surgical tools ensures they perform their function without introducing contaminants or causing adverse tissue reactions.

Ultimately, leveraging PTFE's profound biocompatibility allows for the design of medical devices that are fundamentally safer and more reliable.

Summary Table:

| Application | Key Benefit of PTFE Biocompatibility |

|---|---|

| Vascular Grafts | Prevents immune rejection and clotting for long-term implantation. |

| Catheters & Endoscopes | Minimizes tissue irritation and enables smooth, safe insertion. |

| Surgical Instruments | Ensures no contamination or reaction with sensitive tissues and fluids. |

Need a reliable, biocompatible PTFE component for your medical device?

At KINTEK, we specialize in manufacturing high-precision, medical-grade PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our commitment to precision production and custom fabrication, from prototypes to high-volume orders, ensures your device meets the highest standards of patient safety and performance.

Contact us today to discuss how our PTFE solutions can enhance your medical application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability