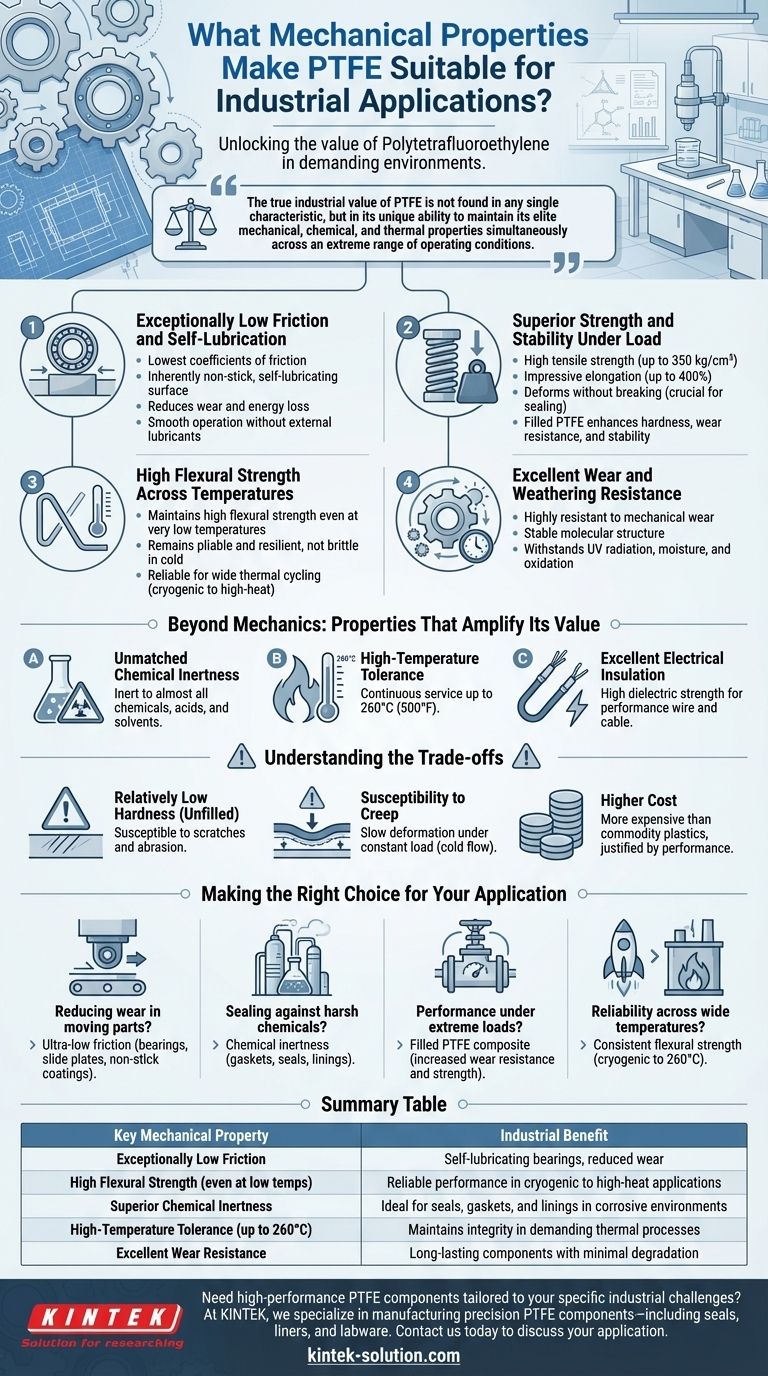

At its core, Polytetrafluoroethylene (PTFE) is prized in industrial settings for an exceptional combination of mechanical properties. Its value stems from its extremely low friction, high flexural strength even at low temperatures, and excellent stability under load. These characteristics, combined with its profound chemical and thermal resistance, make it one of the most versatile and reliable materials for demanding engineering challenges.

The true industrial value of PTFE is not found in any single characteristic, but in its unique ability to maintain its elite mechanical, chemical, and thermal properties simultaneously across an extreme range of operating conditions.

The Core Mechanical Advantages of PTFE

To understand why PTFE is specified for critical components like bearings, seals, and gaskets, we must examine its fundamental mechanical behaviors.

Exceptionally Low Friction and Self-Lubrication

PTFE possesses one of the lowest coefficients of friction of any known solid material. This creates an inherently non-stick, self-lubricating surface.

This property directly reduces wear and energy loss in dynamic systems. It allows parts like bearings and joints to operate smoothly for extended periods without external lubricants, minimizing maintenance and preventing seizure.

Superior Strength and Stability Under Load

While not as rigid as metal, PTFE exhibits a high tensile strength (up to 350 kg/cm²) and impressive elongation (up to 400%). This allows it to deform without breaking, a crucial trait for sealing applications.

For applications involving extreme loads, filled PTFE is used. By adding agents like glass, carbon, or graphite, the material’s hardness, wear resistance, and stability are significantly enhanced while retaining its low-friction nature.

High Flexural Strength Across Temperatures

A key differentiator for PTFE is its ability to maintain high flexural strength even at very low temperatures. Unlike many polymers that become brittle and fracture in the cold, PTFE remains pliable and resilient.

This makes it a reliable choice for applications that experience wide thermal cycling, from cryogenic systems to high-heat industrial processes.

Excellent Wear and Weathering Resistance

PTFE is highly resistant to degradation from mechanical wear and environmental weathering. Its molecular structure is extremely stable, allowing it to withstand long-term exposure to UV radiation, moisture, and oxidation without compromising its integrity.

Beyond Mechanics: Properties That Amplify Its Value

PTFE’s mechanical properties do not exist in a vacuum. Their value is magnified by a set of equally powerful thermal, chemical, and electrical characteristics.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, acids, and solvents. This makes it the default choice for components that handle corrosive or hazardous materials.

Applications like gaskets, O-rings, and linings for chemical pipework rely on this property to ensure system integrity and prevent dangerous leaks.

High-Temperature Tolerance

Standard PTFE maintains its properties and structure at continuous service temperatures up to 260°C (500°F). This allows it to perform reliably in high-temperature engines, processing equipment, and manufacturing environments where lesser materials would melt or degrade.

Excellent Electrical Insulation

PTFE has a very high dielectric strength, making it an outstanding electrical insulator. This property, combined with its heat resistance, makes it ideal for high-performance wire and cable insulation, especially in aerospace and computing where performance and safety are paramount.

Understanding the Trade-offs

No material is perfect. Acknowledging PTFE's limitations is critical for proper application and design.

Relatively Low Hardness (Unfilled)

In its unfilled, or "virgin," state, PTFE is a relatively soft material. It has lower tensile and compressive strength compared to many engineering plastics and is susceptible to scratches and abrasion from hard particulates.

Susceptibility to Creep

Under a constant compressive load, PTFE can be subject to "creep" or "cold flow," meaning it will slowly deform over time. Engineers must account for this phenomenon in designs, especially for high-pressure gaskets, to ensure a long-lasting seal.

Higher Cost

As a high-performance fluoropolymer, PTFE is more expensive than common commodity plastics like polyethylene or polypropylene. Its use is therefore justified by performance requirements that other materials cannot meet.

Making the Right Choice for Your Application

Selecting the right material requires matching its properties to your primary goal.

- If your primary focus is reducing wear in moving parts: PTFE's ultra-low coefficient of friction makes it the ideal choice for bearings, slide plates, and non-stick coatings.

- If your primary focus is sealing against harsh chemicals: Its chemical inertness makes it the premier material for gaskets, seals, and linings in chemical processing.

- If your primary focus is performance under extreme loads: Specify a "filled PTFE" composite to gain the necessary wear resistance and strength for high-pressure systems.

- If your primary focus is reliability across a wide temperature range: Its consistent flexural strength from cryogenic lows to 260°C makes it uniquely suited for aerospace and industrial equipment.

By understanding this balance of elite properties and practical limitations, you can leverage PTFE to solve some of the most demanding industrial challenges.

Summary Table:

| Key Mechanical Property | Industrial Benefit |

|---|---|

| Exceptionally Low Friction | Self-lubricating bearings, reduced wear in moving parts |

| High Flexural Strength (even at low temps) | Reliable performance in cryogenic to high-heat applications |

| Superior Chemical Inertness | Ideal for seals, gaskets, and linings in corrosive environments |

| High-Temperature Tolerance (up to 260°C) | Maintains integrity in demanding thermal processes |

| Excellent Wear Resistance | Long-lasting components with minimal degradation |

Need high-performance PTFE components tailored to your specific industrial challenges?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get parts that deliver superior mechanical performance, chemical resistance, and reliability.

Contact us today to discuss how our PTFE solutions can enhance your application's efficiency and durability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments