At its core, the versatility of Teflon membranes in the laboratory stems from a powerful combination of three key properties: near-total chemical inertness, exceptional thermal stability, and a hydrophobic nature that makes them suitable for filtering both gases and liquids. This unique blend allows a single membrane type to function reliably across an incredibly wide range of aggressive chemicals, extreme temperatures, and diverse experimental conditions.

The true value of Teflon (PTFE) isn't just one superior feature, but its ability to act as a non-reactive, non-interfering, and durable barrier in almost any scientific scenario, ensuring the integrity of the experiment and the purity of the sample.

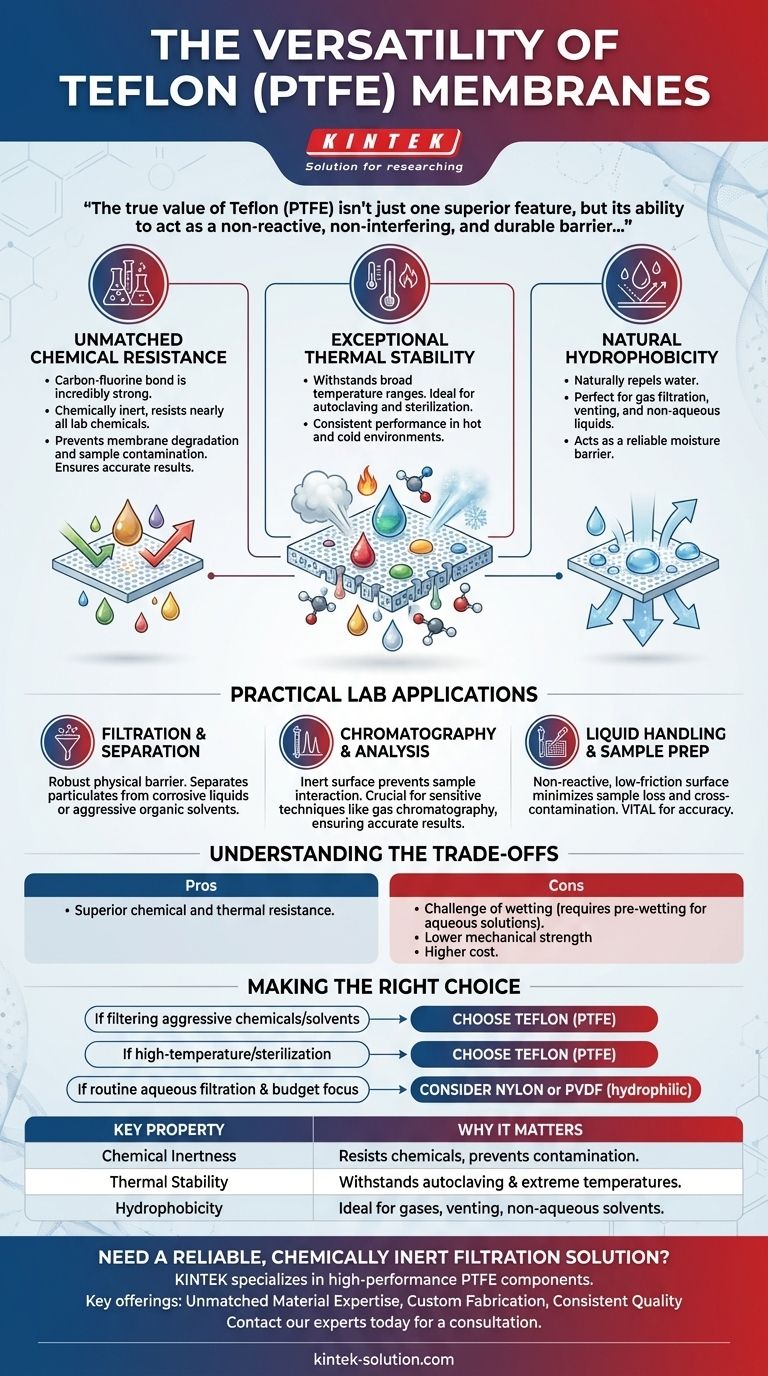

The Three Pillars of Teflon's Versatility

Teflon, technically known as PTFE (polytetrafluoroethylene), is a synthetic fluoropolymer. Its molecular structure is responsible for the unique properties that make it an indispensable tool in modern laboratories.

Unmatched Chemical Resistance

The carbon-fluorine bond in PTFE is one of the strongest in organic chemistry. This makes the material chemically inert, meaning it will not react with or degrade when exposed to nearly all common laboratory chemicals.

This property is critical for preventing two major problems: the degradation of the membrane itself and the contamination of the sample being filtered. It ensures that your results are accurate and untainted by unintended reactions.

Exceptional Thermal Stability

Teflon membranes can withstand a very broad range of temperatures without losing their structural integrity or mechanical properties.

This allows them to be used in processes involving extreme heat, such as autoclaving and sterilization, which is essential for sterile filtration applications. Their performance remains consistent and reliable whether the environment is hot or cold.

Natural Hydrophobicity

Teflon naturally repels water, a property known as hydrophobicity. This makes it an ideal material for filtering gases, venting applications, and filtering non-aqueous liquids and aggressive solvents.

Because it prevents water from passing through without sufficient pressure, it acts as a reliable barrier for moisture-sensitive processes.

How Versatility Translates to Practical Lab Applications

These fundamental properties enable Teflon membranes to be used in a wide array of critical laboratory equipment and procedures, ensuring precision and reliability.

Filtration and Separation

In filtration systems, Teflon membranes act as a robust physical barrier. They can separate particulates from highly corrosive liquids or aggressive organic solvents that would destroy other membrane materials.

Chromatography and Analysis

The inert surface of Teflon is crucial in sensitive analytical techniques like gas chromatography. It ensures that the membrane or tubing does not interact with the sample, which could alter the composition and lead to inaccurate results.

Liquid Handling and Sample Prep

Devices used for controlled dispensing and sample preparation benefit from Teflon's non-reactive and low-friction surface. This minimizes sample loss due to adhesion and prevents cross-contamination between different substances, which is vital for maintaining experimental accuracy.

Understanding the Trade-offs

While extremely versatile, Teflon membranes are not the universal solution for every single application. A clear understanding of their limitations is key to making an informed decision.

The Challenge of Wetting

Their natural hydrophobicity is a disadvantage when filtering aqueous (water-based) solutions. A Teflon membrane must first be pre-wetted with a solvent like ethanol or isopropanol before it will allow water to pass through. This adds an extra step to the workflow.

Mechanical Strength

Compared to some other polymers, PTFE can be softer and may not be the first choice for very high-pressure filtration systems where mechanical strength is the single most important factor.

Cost Considerations

Generally, Teflon membranes are more expensive than other common membrane types like nylon or mixed cellulose ester. Their use is a trade-off between the need for superior chemical and thermal resistance versus the project's budget.

Making the Right Choice for Your Goal

Selecting the correct membrane requires matching its properties to the specific demands of your experiment.

- If your primary focus is filtering aggressive chemicals or organic solvents: Teflon (PTFE) is the safest and most reliable choice due to its unparalleled chemical inertness.

- If your primary focus is high-temperature applications like sterilization: Teflon's thermal stability ensures the membrane will not fail or leach contaminants when exposed to heat.

- If your primary focus is routine aqueous filtration on a tight budget: A naturally hydrophilic membrane like nylon or PVDF might be a more efficient and cost-effective option, as it eliminates the need for pre-wetting.

Ultimately, understanding the unique strengths and limitations of Teflon allows you to leverage its power for the most demanding applications while making practical choices for everyday tasks.

Summary Table:

| Key Property | Why It Matters for Lab Use |

|---|---|

| Chemical Inertness | Resists virtually all lab chemicals, preventing sample contamination and membrane degradation. |

| Thermal Stability | Withstands autoclaving and extreme temperatures for sterilization and high-heat processes. |

| Hydrophobicity | Ideal for filtering gases, venting, and non-aqueous solvents; repels water effectively. |

Need a Reliable, Chemically Inert Filtration Solution?

Teflon (PTFE) membranes are essential for ensuring the integrity of your most demanding experiments in the semiconductor, medical, and laboratory industries. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including custom membranes, seals, and labware.

We provide:

- Unmatched Material Expertise: Ensuring your components meet the highest standards for chemical resistance and thermal stability.

- Custom Fabrication: From prototype development to high-volume production, tailored to your specific application requirements.

- Consistent Quality: Guaranteeing reliable performance for critical processes like sterile filtration and chromatography.

Let's discuss how our PTFE solutions can enhance your lab's capabilities. Contact our experts today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support