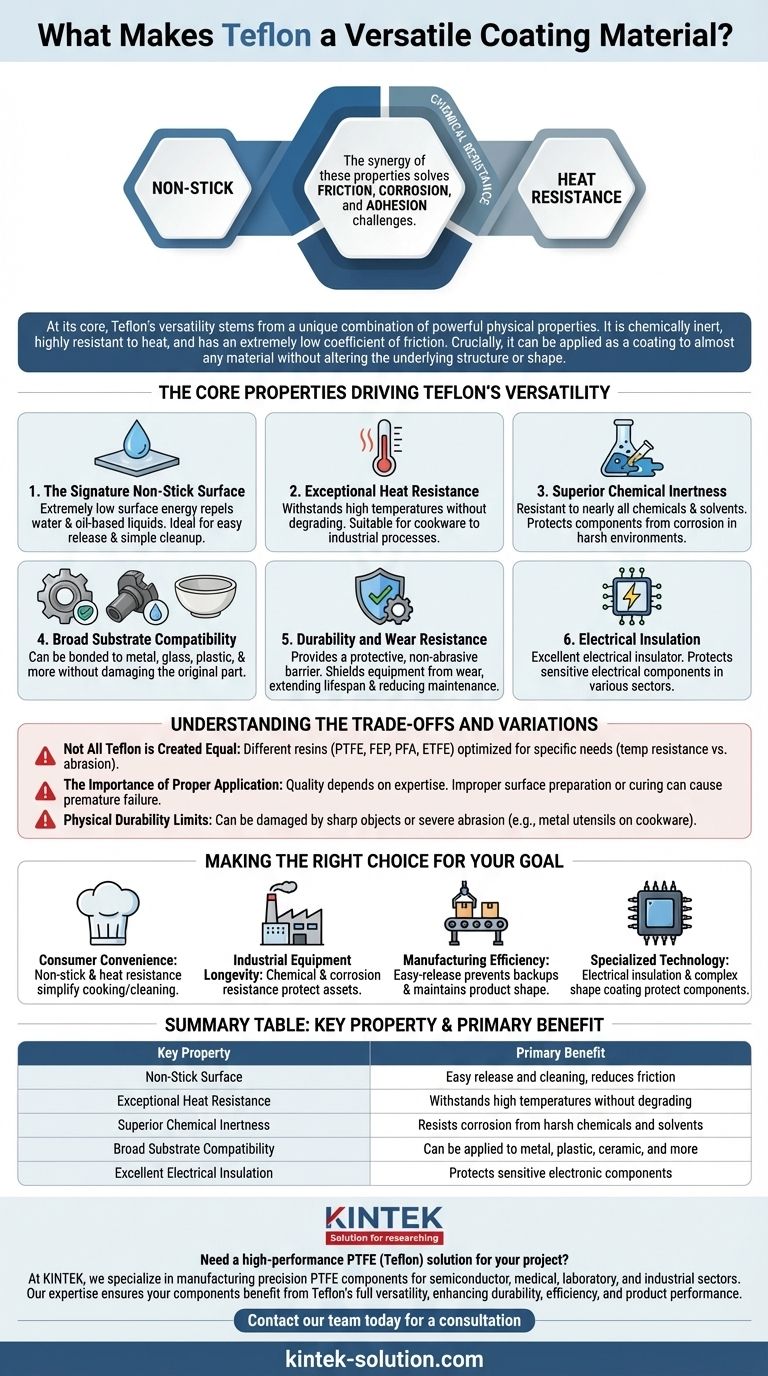

At its core, Teflon's versatility stems from a unique combination of powerful physical properties. It is chemically inert, highly resistant to heat, and has an extremely low coefficient of friction, creating its signature non-stick surface. Crucially, it can be applied as a coating to almost any material—from metal and plastic to ceramic—without altering the underlying structure or shape.

The true source of Teflon's adaptability is not any single trait, but the synergy of its non-stick, chemical-resistant, and heat-resistant properties. This combination solves a wide range of common engineering and consumer challenges related to friction, corrosion, and adhesion.

The Core Properties Driving Teflon's Versatility

Teflon is a brand name for a class of fluoropolymers, most famously Polytetrafluoroethylene (PTFE). Its molecular structure is responsible for a set of characteristics that are rarely found together in a single material.

The Signature Non-Stick Surface

Teflon has an incredibly low surface energy, which means other substances have a very hard time sticking to it.

This property repels both water and oil-based liquids, making it ideal for applications where easy release and simple cleanup are required.

Exceptional Heat Resistance

Teflon coatings can withstand high temperatures without degrading.

This makes them suitable for everything from high-temperature cookware to demanding industrial processes where equipment is exposed to extreme heat.

Superior Chemical Inertness

Teflon is resistant to nearly all chemicals and solvents.

This non-reactive nature means it can be used to coat equipment in harsh chemical manufacturing environments, protecting components from corrosion and extending their operational life.

Broad Substrate Compatibility

A key factor in its versatility is its ability to be applied to a vast array of materials.

Whether the base material is metal, glass, or plastic, a Teflon coating can be bonded to it without damaging the integrity of the original part.

Durability and Wear Resistance

Teflon provides a protective, non-abrasive barrier.

This shields equipment and tools from general wear and tear, significantly extending their lifespan and reducing maintenance costs in industrial settings.

Electrical Insulation

In addition to its other properties, Teflon is also an excellent electrical insulator.

This makes it a critical material in the construction, automotive, and technology sectors for protecting sensitive electrical components.

Understanding the Trade-offs and Variations

While incredibly versatile, Teflon is not a one-size-fits-all solution. Understanding its limitations and variations is key to using it effectively.

Not All Teflon is Created Equal

The "Teflon" brand encompasses several different types of resins, such as PTFE, FEP, PFA, and ETFE.

Each formulation is engineered to optimize for specific needs. For example, one type might offer maximum temperature resistance at the expense of some flexibility, while another provides superior abrasion resistance for high-contact machinery.

The Importance of Proper Application

The performance of a Teflon coating is highly dependent on the quality of its application.

Improper surface preparation or curing can lead to a weak bond, causing the coating to fail prematurely. Its effectiveness is tied directly to the expertise of the application process.

Physical Durability Limits

While durable against chemical attack and general wear, Teflon coatings can be damaged by sharp objects or severe abrasion.

This is a well-known limitation in consumer cookware, where metal utensils can scratch and compromise the non-stick surface.

Making the Right Choice for Your Goal

The optimal use of Teflon depends entirely on the primary problem you need to solve.

- If your primary focus is consumer convenience (like cookware): The non-stick surface and heat resistance are the most valuable properties, simplifying cooking and cleaning.

- If your primary focus is industrial equipment longevity: The chemical inertness and corrosion resistance are paramount for protecting assets in harsh environments.

- If your primary focus is manufacturing efficiency (like food processing): The easy-release quality is critical for ensuring products maintain their shape and preventing production line backups.

- If your primary focus is specialized technology: The electrical insulation and ability to coat complex shapes are the key factors for protecting sensitive components.

Ultimately, Teflon's enduring value comes from its ability to solve multiple problems at once across an unmatched range of applications.

Summary Table:

| Key Property | Primary Benefit |

|---|---|

| Non-Stick Surface | Easy release and cleaning, reduces friction |

| Exceptional Heat Resistance | Withstands high temperatures without degrading |

| Superior Chemical Inertness | Resists corrosion from harsh chemicals and solvents |

| Broad Substrate Compatibility | Can be applied to metal, plastic, ceramic, and more |

| Excellent Electrical Insulation | Protects sensitive electronic components |

Need a high-performance PTFE (Teflon) solution for your project?

At KINTEK, we specialize in manufacturing precision PTFE components—including custom coatings, seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components benefit from Teflon's full versatility, enhancing durability, efficiency, and product performance.

Let's discuss how we can apply our expertise to your specific challenge.

Contact our team today for a consultation to explore custom fabrication from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability