The fundamental reason PTFE washers are suitable for high-temperature environments is their unique molecular structure. The exceptionally strong carbon-fluorine bonds that make up the Polytetrafluoroethylene (PTFE) polymer give it a very high melting point and thermal stability, allowing it to maintain its form and function at continuous service temperatures up to +260°C (500°F).

While its ability to withstand high heat is the primary draw, PTFE's true value comes from its combination of thermal stability, near-total chemical inertness, and extremely low friction—a trio of properties that allows it to outperform other materials in demanding industrial environments.

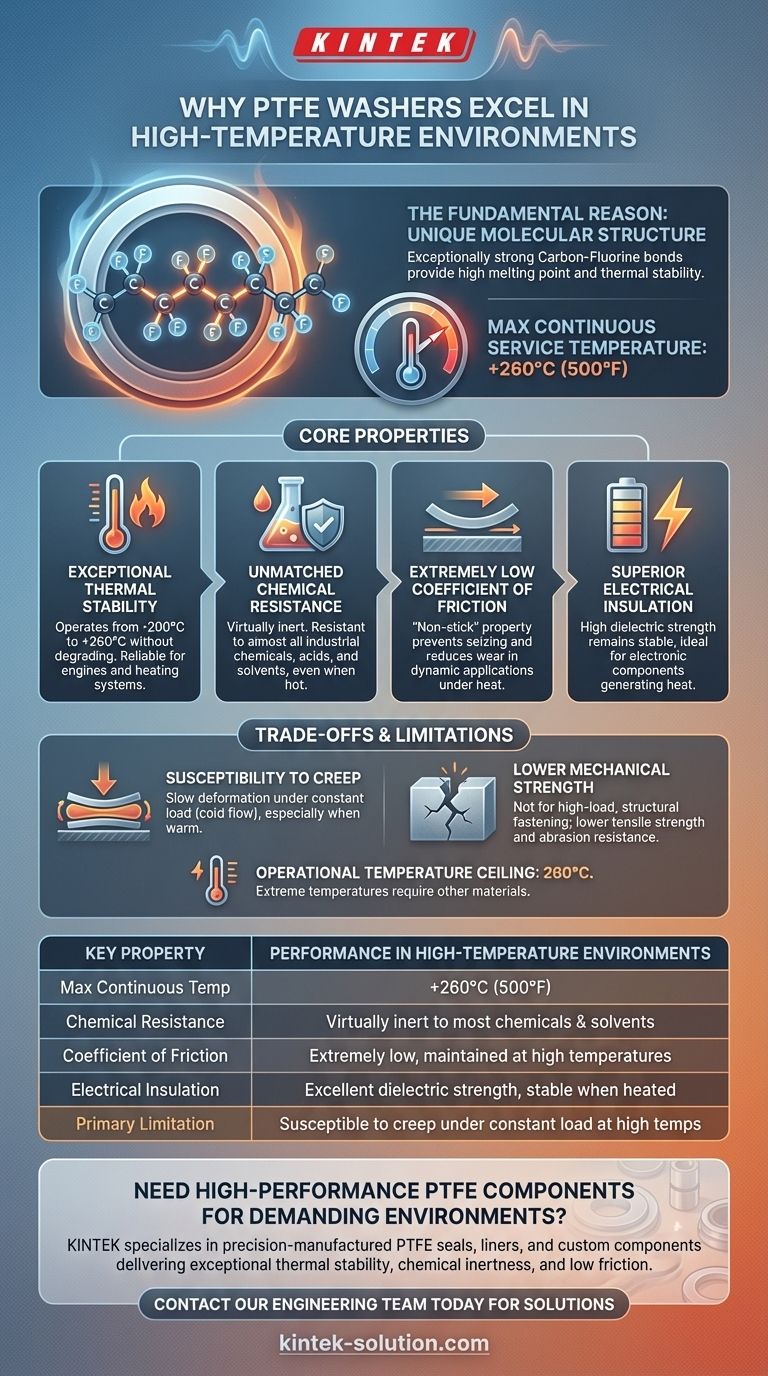

The Core Properties of PTFE in High-Heat Scenarios

To fully understand PTFE's effectiveness, we must look beyond just its temperature tolerance. Several key characteristics work in concert to make it a superior choice for hot and challenging applications.

Exceptional Thermal Stability

PTFE washers operate effectively across an incredibly wide temperature range, from cryogenic lows of -200°C (-328°F) up to a high of +260°C (500°F).

Unlike many plastics that become brittle or melt, PTFE retains its critical properties without degrading within this range, making it reliable for engines, heating systems, and industrial processing.

Unmatched Chemical Resistance

High temperatures often accelerate chemical reactions and corrosion. PTFE is virtually inert and resistant to almost all industrial chemicals, acids, and solvents.

This means that even in a hot, corrosive environment, a PTFE washer will not degrade or contaminate the system, which is critical in chemical processing, pharmaceutical, and food industries.

Extremely Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" property is maintained even at elevated temperatures.

In dynamic applications with moving parts, this prevents seizing and reduces wear, ensuring smooth operation where heat and friction would cause other materials to fail.

Superior Electrical Insulation

Heat can compromise the insulating capabilities of many materials. PTFE is an excellent electrical insulator with high dielectric strength that remains stable at high temperatures.

This makes it an ideal choice for mounting components in electronic devices and systems where heat is generated during operation.

Understanding the Trade-offs and Limitations

No material is perfect for every situation. Being an effective advisor means acknowledging the specific limitations of PTFE, especially in the context of heat.

Susceptibility to Creep

PTFE is a relatively soft material. Under a constant compressive load, especially when warm, it can slowly deform over time in a process known as "creep" or "cold flow."

This makes it less suitable for high-pressure structural applications where maintaining a precise, constant thickness under heavy load is critical.

Lower Mechanical Strength

Compared to metal or even some high-performance engineering plastics, PTFE has lower tensile strength and abrasion resistance.

It is designed for sealing and insulation, not for high-load, structural fastening. Using it in the wrong application can lead to mechanical failure.

The Operational Temperature Ceiling

While 260°C is an impressive ceiling for a polymer, many industrial processes in metallurgy or aerospace can far exceed this.

For applications involving extreme temperatures beyond this limit, materials like graphite, ceramics, or high-performance metal alloys must be considered instead.

Making the Right Choice for Your Application

Selecting the correct washer depends entirely on the specific demands of your environment.

- If your primary focus is sealing a static joint in a hot, corrosive environment: PTFE is an excellent choice due to its combined thermal and chemical stability.

- If your application involves moving parts and friction under heat: PTFE's uniquely low coefficient of friction makes it an ideal bearing or dynamic seal.

- If you require a high-strength fastener for a structural load at high temperature: PTFE is unsuitable; you should evaluate high-temperature steel, titanium, or ceramic washers.

Ultimately, choosing PTFE for a high-temperature application is a decision based on its unparalleled combination of thermal, chemical, and frictional properties.

Summary Table:

| Key Property | Performance in High-Temperature Environments |

|---|---|

| Max Continuous Temperature | +260°C (500°F) |

| Chemical Resistance | Virtually inert to almost all chemicals and solvents |

| Coefficient of Friction | Extremely low, maintained even at high temperatures |

| Electrical Insulation | Excellent dielectric strength, stable when heated |

| Primary Limitation | Susceptible to creep under constant load at high temperatures |

Need high-performance PTFE components for demanding environments?

At KINTEK, we specialize in precision-manufactured PTFE seals, liners, labware, and custom components that deliver exceptional thermal stability, chemical inertness, and low friction—exactly the properties detailed in this article. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your components perform reliably under extreme conditions.

We offer custom fabrication from prototypes to high-volume orders, tailored to your specific application requirements.

Contact our engineering team today to discuss how our PTFE solutions can solve your high-temperature challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments