In short, PTFE washers are suitable for electrical applications because they are one of the best electrical insulators known. Their unique molecular structure gives them exceptionally high electrical resistance and dielectric strength, which allows them to effectively prevent the flow of current and resist electrical breakdown, ensuring both safety and reliable performance in electronic components.

Choosing the right material for electrical insulation is a critical decision that directly impacts component safety and longevity. PTFE stands out not just for its initial insulating capability, but for its remarkable ability to maintain that performance across a wide range of temperatures and environmental conditions, making it a superior choice for demanding applications.

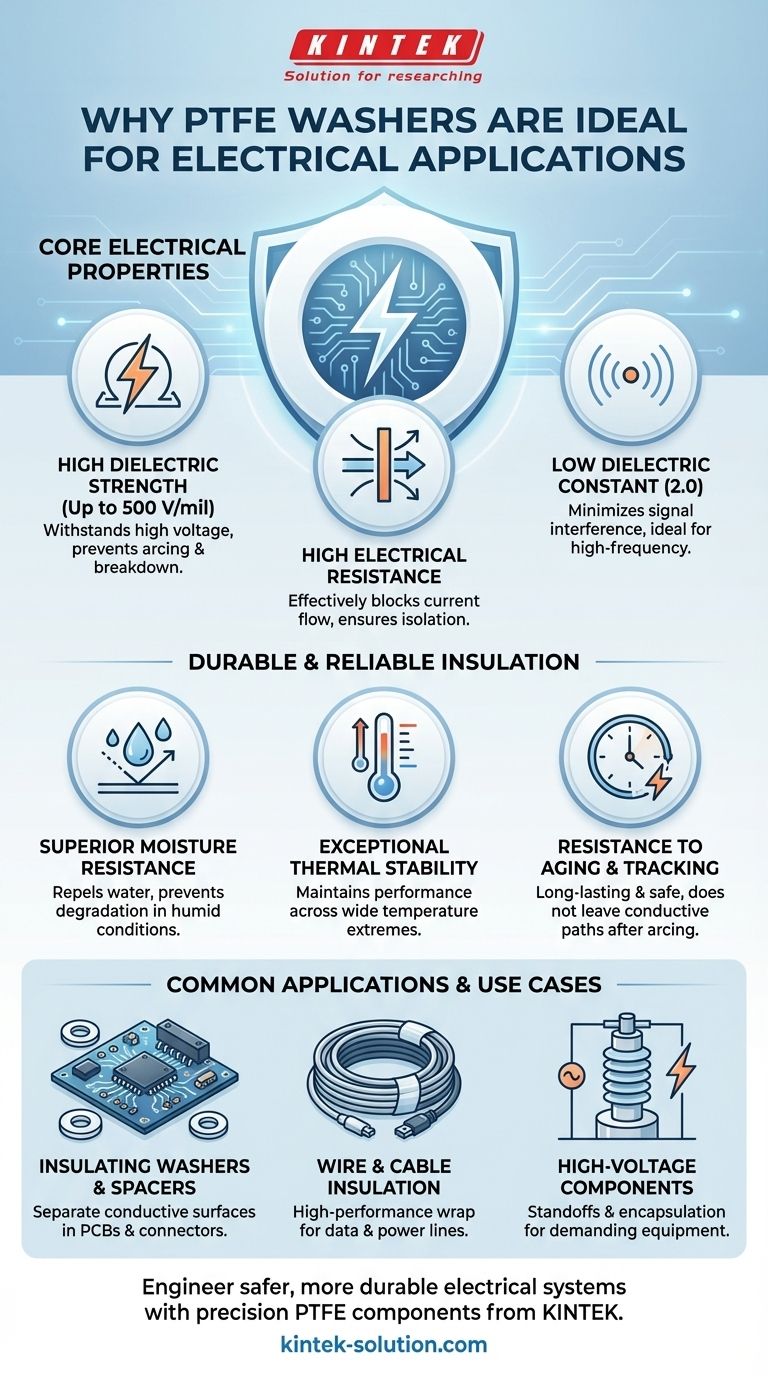

The Core Electrical Properties of PTFE

The suitability of PTFE as an electrical insulator stems from a combination of specific, measurable electrical properties that few other materials can match.

High Dielectric Strength

Dielectric strength is a measure of a material's ability to withstand high voltage without failing and allowing current to pass through.

PTFE has an outstanding dielectric strength, capable of insulating up to 500 volts per mil in thin sections. This makes it extremely effective at preventing electrical arcing or short circuits, even in high-voltage scenarios.

High Electrical Resistance

PTFE is highly resistant to the flow of electrical current, a fundamental requirement for any insulator.

This property ensures that components separated by a PTFE washer remain electrically isolated, which is critical for the proper functioning of connectors, terminals, and circuit boards.

Low Dielectric Constant

A material's dielectric constant indicates its ability to store electrical energy. For an insulator, a lower value is better as it minimizes interference with electrical signals.

PTFE has a very low dielectric constant (2.0) and a low dissipation factor. This means it does not store significant electrical energy or waste it as heat, making it ideal for high-frequency applications like data cables and semiconductors where signal integrity is paramount.

Why PTFE is a Durable and Reliable Insulator

Beyond its immediate electrical characteristics, PTFE's long-term stability and resistance to environmental factors make it a more durable choice than common alternatives.

Superior Resistance to Moisture

Moisture is a primary cause of insulation failure. PTFE naturally resists water penetration and is not wetted by it.

This quality ensures its insulating properties do not degrade over time due to humidity or direct water contact, unlike materials such as nylon or PVC.

Exceptional Thermal Stability

Electrical components often operate at high temperatures, which can compromise the integrity of many plastic insulators.

PTFE maintains its excellent electrical properties across a wide range of temperatures, ensuring consistent and reliable performance whether the component is in a hot engine bay or a cold external environment.

Resistance to Aging and Tracking

PTFE is highly resistant to weathering and aging, maintaining its physical and electrical integrity over many years of service.

Furthermore, if subjected to electrical arcing, it does not leave a conductive carbon track. This is a critical safety feature that prevents a permanent path for current to flow after a fault event.

Common Applications and Use Cases

These properties make PTFE a versatile material used across a wide spectrum of electrical and electronic systems.

Insulating Washers and Spacers

The most direct application is using machined washers to separate conductive surfaces. This is common in electrical connectors, terminals, and mounting hardware for circuit boards to prevent short circuits.

Wire and Cable Insulation

PTFE is frequently used as a high-performance wrap for wires and cables. Its thermal stability and low dielectric constant are essential for protecting signals in data cables and power lines operating in extreme conditions.

High-Voltage Components

For more demanding applications, PTFE can be machined into standoff insulators or used as an encapsulation material for high-voltage devices. Its ability to resist electrical breakdown is the key factor for these use cases.

Making the Right Choice for Your Application

To determine if PTFE is the correct choice, consider the primary goal of your design.

- If your primary focus is high-voltage insulation: PTFE's exceptionally high dielectric strength makes it a premier choice for preventing electrical breakdown and ensuring safety.

- If your primary focus is long-term reliability in harsh environments: Its stability across wide temperatures and superior resistance to moisture ensure consistent, predictable performance over the component's lifespan.

- If your primary focus is preserving high-frequency signal integrity: PTFE's low dielectric constant minimizes signal distortion and energy loss, making it ideal for sensitive electronics like data cables and circuit boards.

Ultimately, leveraging PTFE's unique combination of electrical characteristics allows you to engineer safer, more durable, and higher-performing electrical systems.

Summary Table:

| Key Property | Benefit for Electrical Applications |

|---|---|

| High Dielectric Strength | Withstands up to 500 V/mil, preventing electrical breakdown and arcing. |

| High Electrical Resistance | Ensures effective isolation between conductive components. |

| Low Dielectric Constant (2.0) | Minimizes signal distortion, ideal for high-frequency electronics. |

| Thermal Stability | Maintains performance across a wide temperature range. |

| Moisture Resistance | Prevents degradation in humid or wet environments. |

| Resistance to Carbon Tracking | Enhances safety by not leaving conductive paths after arcing. |

Engineer safer, more durable electrical systems with precision PTFE components from KINTEK.

Whether you need high-voltage insulation for semiconductor equipment, reliable seals for medical devices, or custom labware for industrial applications, KINTEK delivers. We specialize in manufacturing high-quality PTFE washers, seals, liners, and more, with custom fabrication from prototypes to high-volume orders.

Contact us today to discuss your specific requirements and leverage our expertise in precision PTFE solutions for your industry.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech