At its core, the versatility of Polytetrafluoroethylene (PTFE) in medicine comes from a unique combination of properties. Its defining characteristics are exceptional biological inertness, extreme chemical resistance, an incredibly low coefficient of friction, and its ability to be processed into a porous structure known as ePTFE.

The key is to see PTFE not as a single solution, but as a platform with two distinct forms. Standard PTFE excels as a chemically inert, non-stick barrier, while expanded PTFE (ePTFE) serves as a porous scaffold for integrating implants directly with the body's own tissue.

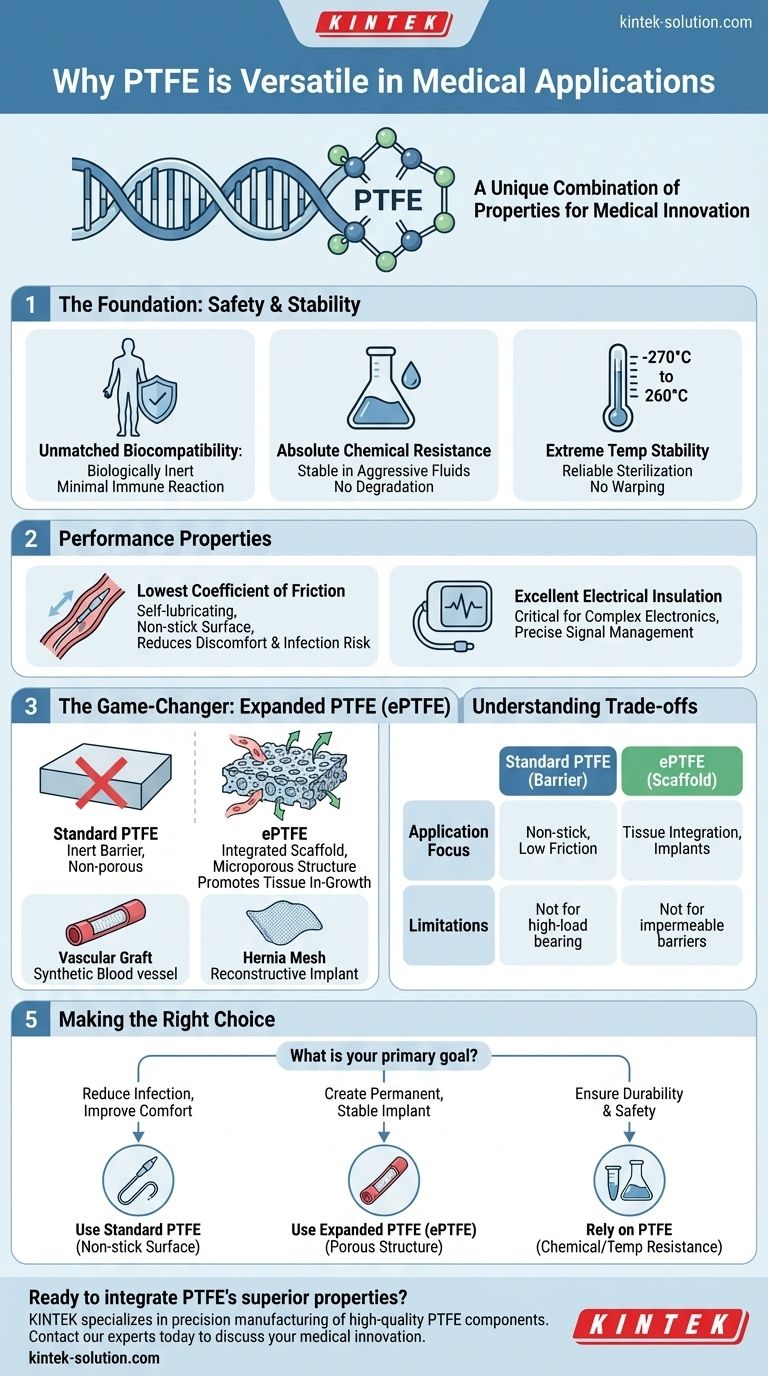

The Foundation: Why PTFE is Fundamentally Safe

Before a material can perform a function in the body, it must first be accepted. PTFE’s fundamental properties ensure it is safe and stable in the demanding biological environment.

Unmatched Biocompatibility

PTFE is one of the most biologically inert materials known. The powerful chemical bonds between its carbon and fluorine atoms create a stable, non-reactive surface.

This means when it's placed inside the body, it triggers a minimal to non-existent immune or tissue reaction. The body effectively ignores it, which is critical for long-term implants.

Absolute Chemical Resistance

The same strong carbon-fluorine bonds that provide biocompatibility also make PTFE almost completely resistant to chemical attack.

It will not degrade when exposed to aggressive bodily fluids, enzymes, or acids. This ensures the material's integrity and prevents the leaching of harmful substances over the device's lifetime.

Extreme Temperature Stability

PTFE maintains its properties across an exceptionally wide temperature range, from -270°C to 260°C.

For medical applications, this high-temperature tolerance is crucial. It means devices made from PTFE can be reliably sterilized using high-heat methods like autoclaving without any risk of melting, warping, or degrading.

Performance Properties in Medical Devices

Beyond being safe, PTFE offers functional properties that solve specific engineering challenges in medicine.

The Lowest Coefficient of Friction

PTFE has one of the lowest friction coefficients of any solid, giving it a self-lubricating and non-stick surface.

This is invaluable for devices like catheters. A PTFE coating allows the device to slide smoothly through blood vessels or other tissues, reducing patient discomfort and minimizing internal damage. This non-stick surface also helps prevent bacteria from adhering, which can reduce the rate of hospital-acquired infections.

Excellent Electrical Insulation

PTFE is a superb electrical insulator. This makes it a critical component in complex medical electronics where electrical signals must be precisely managed and isolated, such as in pacemakers or advanced diagnostic equipment.

The Game-Changer: Expanded PTFE (ePTFE)

While standard PTFE is an excellent barrier, a modified version called expanded PTFE (ePTFE) is designed for the opposite purpose: integration.

From Inert Barrier to Integrated Scaffold

ePTFE is created by expanding the material, which introduces a microporous, mesh-like structure. It is soft, flexible, and strong, but its most important feature is the network of tiny, interconnected pores.

Promoting Tissue In-Growth

This porous structure acts as a scaffold. Instead of being walled off by the body, ePTFE allows the body's own tissue and cells to grow directly into the material's pores.

This integration anchors the implant securely, making it a stable and permanent part of the surrounding tissue.

Key Applications: Grafts and Hernia Repair

This property makes ePTFE the ideal material for vascular grafts, where it functions as a synthetic blood vessel. It is also used extensively in hernia repair meshes and for various reconstructive surgeries where a strong, flexible, and fully integrated implant is required.

Understanding the Trade-offs

While highly versatile, selecting PTFE requires understanding its specific characteristics and limitations.

Not All PTFE is Created Equal

The most critical distinction is between standard PTFE and ePTFE. Using solid PTFE where tissue integration is needed will fail, just as using porous ePTFE where an impermeable barrier is required is incorrect. The application dictates the form.

Mechanical Limitations

PTFE is soft and flexible, not rigid. While this is an advantage for soft tissue applications, it is unsuitable for high-load-bearing implants like artificial joints, which require materials with greater compressive strength like titanium or specialized polymers.

Making the Right Choice for Your Application

To leverage PTFE effectively, your choice must be driven by the primary goal of your medical device.

- If your primary focus is reducing infection and improving patient comfort: Use standard PTFE for its non-stick, low-friction surface on catheters and guidewires.

- If your primary focus is creating a permanent, stable implant: Use expanded PTFE (ePTFE) for its porous structure that encourages tissue integration in vascular grafts and surgical meshes.

- If your primary focus is ensuring device durability and safety: Rely on PTFE's chemical inertness and high-temperature resistance for components that face aggressive fluids or require terminal sterilization.

Ultimately, understanding the distinction between PTFE as an inert barrier and ePTFE as an integrated scaffold is the key to leveraging its full potential in medical innovation.

Summary Table:

| Property | Standard PTFE | Expanded PTFE (ePTFE) |

|---|---|---|

| Primary Function | Inert Barrier | Tissue Integration Scaffold |

| Structure | Solid, Non-porous | Microporous, Mesh-like |

| Key Applications | Catheters, Guidewires, Labware | Vascular Grafts, Hernia Meshes |

| Biocompatibility | High (Biologically Inert) | High (Promotes Tissue In-Growth) |

| Chemical/Temp Resistance | Excellent | Excellent |

Ready to integrate PTFE's superior properties into your medical device?

At KINTEK, we specialize in the precision manufacturing of high-quality PTFE components—from custom seals and liners to complex labware—for the medical, semiconductor, and laboratory industries. Whether you need the non-stick barrier of standard PTFE or the tissue-integrating scaffold of ePTFE, our custom fabrication services, from prototypes to high-volume orders, ensure your device meets the highest standards of safety and performance.

Contact our experts today to discuss how our PTFE solutions can enhance your next medical innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials