At their core, PTFE V-rings are effective because they combine a clever, multi-lip mechanical design with the exceptional material properties of Polytetrafluoroethylene (PTFE). This synergy creates a robust, low-friction seal that automatically adjusts to system pressure and resists harsh operating conditions where other seals would fail.

The effectiveness of a PTFE V-ring is not due to a single feature, but rather the powerful interaction between its stacked, pressure-energizing shape and PTFE's inherent resistance to friction, chemicals, and extreme temperatures.

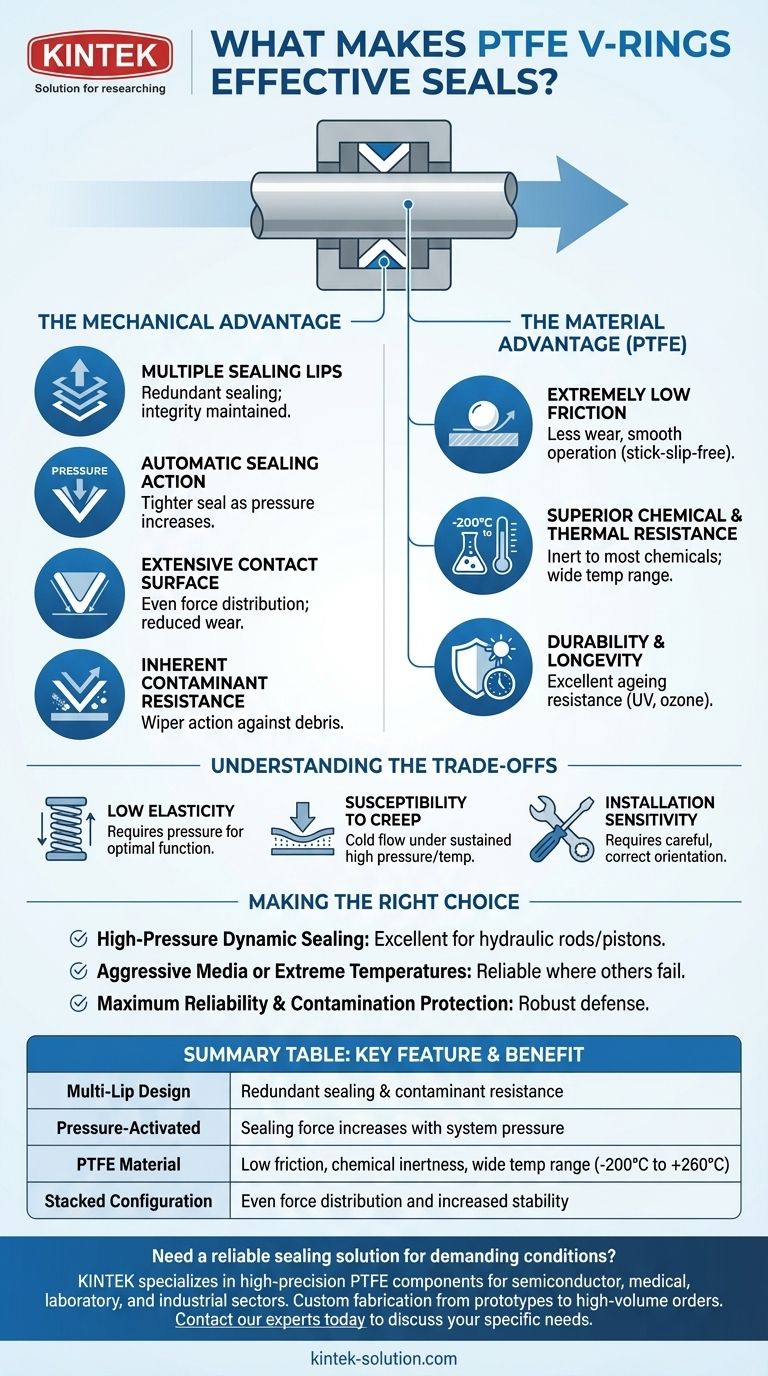

The Mechanical Advantage: How the V-Ring Design Works

The physical structure of a V-ring set is engineered for performance and resilience. It consists of a stack of nested rings, including a pressure ring, multiple V-shaped sealing rings, and a backup ring.

Multiple Sealing Lips

Each individual "V" in the stack functions as an independent sealing lip. This redundancy means that if one lip encounters a minor imperfection or contaminant, the others maintain the seal's integrity.

Automatic Sealing Action

The V-shape is designed to be pressure-activated. As system pressure increases, it acts on the open side of the "V," forcing the lips outward against the sealing surfaces. This creates a tighter seal precisely when it's needed most.

Extensive Contact Surface

The stacked design provides a large contact area with the rod or bore. This distributes the sealing force more evenly, reducing localized wear and increasing the overall stability and lifespan of the seal.

Inherent Contaminant Resistance

The series of lips acts like a set of wipers. This configuration makes the seal less susceptible to failure from contaminants in the working medium, as the outer rings can scrape away debris before it reaches the primary inner seals.

The Material Advantage: Why PTFE is the Ideal Choice

While the design is critical, it is the unique properties of PTFE that enable the V-ring to function in the most demanding environments.

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This results in less wear, lower heat generation, and smooth, stick-slip-free operation, which is critical in dynamic applications.

Superior Chemical and Thermal Resistance

PTFE is virtually inert, meaning it is resistant to almost all industrial chemicals and solvents. It also maintains its properties across a vast temperature range (–200°C to +260°C), where traditional elastomers would degrade or become brittle.

Durability and Longevity

The material exhibits excellent ageing resistance, meaning it won't break down due to exposure to UV light or ozone. Its high elongation also allows for easier fitting during installation without causing damage.

Understanding the Trade-offs

No sealing solution is perfect for every scenario. It is crucial to understand the limitations of PTFE to ensure proper application.

Low Elasticity

Unlike rubber, PTFE has poor elastic memory. It does not spring back to its original shape easily after being deformed. The V-ring's pressure-activating design compensates for this, but it means the seal relies on system pressure to function optimally.

Susceptibility to Creep

Under sustained high pressure and temperature, PTFE can be prone to "cold flow" or creep, where the material slowly deforms over time. The inclusion of fillers in the PTFE compound and the use of rigid backup rings are common strategies to mitigate this.

Installation Sensitivity

A multi-component V-ring set requires more care during installation than a simple O-ring. Proper orientation of the pressure and backup rings is essential for the seal to function correctly.

Making the Right Choice for Your Application

To determine if a PTFE V-ring is the correct solution, consider your primary operational challenge.

- If your primary focus is high-pressure dynamic sealing: The automatic, pressure-energizing design and low-friction performance make it an excellent choice for hydraulic rods and pistons.

- If your primary focus is aggressive media or extreme temperatures: PTFE's inherent chemical and thermal resistance provides reliability where other materials would quickly fail.

- If your primary focus is maximum reliability and contamination protection: The redundant, multi-lip configuration offers a robust defense against system contaminants and seal failure.

By understanding how this seal's intelligent design leverages a high-performance material, you can confidently specify it for your most challenging applications.

Summary Table:

| Key Feature | Benefit |

|---|---|

| Multi-Lip Design | Redundant sealing & contaminant resistance |

| Pressure-Activated | Sealing force increases with system pressure |

| PTFE Material | Low friction, chemical inertness, wide temp range (-200°C to +260°C) |

| Stacked Configuration | Even force distribution and increased stability |

Need a reliable sealing solution for demanding conditions?

PTFE V-rings are ideal for applications where high pressure, extreme temperatures, or aggressive chemicals cause other seals to fail. KINTEK specializes in manufacturing high-precision PTFE components, including custom V-rings, for the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring you get a seal perfectly tailored to your application's requirements.

Contact our experts today to discuss your specific needs and discover how our PTFE solutions can enhance your system's performance and reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications