At its core, Polytetrafluoroethylene (PTFE) is suitable for applications requiring reduced friction because it has the lowest coefficient of friction of any known solid material. This unique characteristic allows it to function as an exceptionally slick, non-stick surface even without external lubrication, making it a premier choice for self-lubricating mechanical parts.

The true value of PTFE is not just its unparalleled low friction, but how this core property works in concert with its extreme chemical and thermal resistance to solve engineering problems where traditional lubricants would fail or cause contamination.

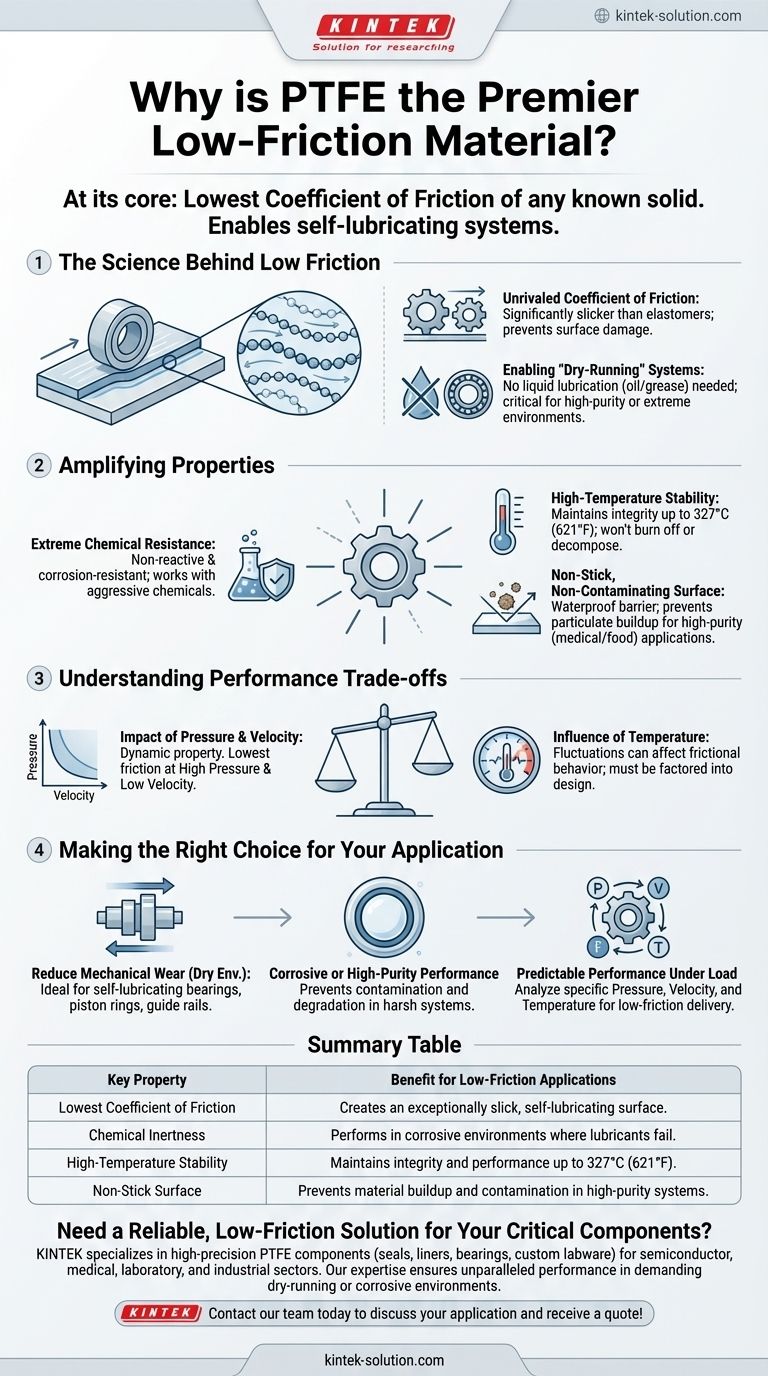

The Science Behind PTFE's Low Friction

PTFE's effectiveness stems from its fundamental material properties. It doesn't just reduce friction; it redefines how mechanical components can interact in demanding environments.

An Unrivaled Coefficient of Friction

The most critical property is PTFE's coefficient of friction, which is lower than any other solid. This makes it significantly slicker than even the elastomers used in common rubber seals.

This inherent lubricity means it can prevent the damage and degradation that friction causes to the mating surfaces and parts it comes into contact with.

Enabling "Dry-Running" Systems

Because of its extremely low friction, PTFE can be used in "dry-running" conditions. This means it requires no liquid lubrication like oil or grease to perform its function.

This is a critical advantage in applications where lubricants are undesirable, such as in high-purity systems, or where they would break down due to high temperatures or chemical exposure.

How Supporting Properties Amplify Its Value

PTFE's low friction is made even more powerful by its other inherent characteristics. These properties allow it to be deployed in environments where other materials would quickly fail.

Extreme Chemical Resistance

PTFE is almost entirely non-reactive and corrosion-resistant. This allows it to be used as a seal or bearing in contact with aggressive chemicals without degrading.

High-Temperature Stability

With a melting point around 327°C (621°F), PTFE maintains its integrity and low-friction properties in high-temperature mechanical systems where traditional lubricants would burn off or decompose.

A Non-Stick, Non-Contaminating Surface

The material is non-stick and waterproof, creating an effective protective barrier. Its smooth surface also prevents particulate buildup.

This makes it ideal for high-purity applications in medical or food processing, as it reduces the risk of system contamination.

Understanding the Performance Trade-offs

While PTFE's performance is exceptional, it is not absolute. Its frictional characteristics are influenced by the operating conditions of the application, a factor that any engineer must consider.

The Impact of Pressure and Velocity

The coefficient of friction in PTFE is not a static number; it is a dynamic property. The lowest friction is typically achieved under conditions of high pressure and low sliding velocities.

Engineers must account for these variables when designing components to ensure the material performs as expected under the system's specific loads and speeds.

The Influence of Temperature

Temperature is another critical variable. While PTFE has a high melting point, significant temperature fluctuations can influence its frictional behavior and mechanical properties, which must be factored into the design.

Making the Right Choice for Your Application

To leverage PTFE effectively, align its properties with your primary engineering goal.

- If your primary focus is reducing mechanical wear in a dry environment: PTFE is the ideal choice for creating self-lubricating components like bearings, piston rings, and guide rails.

- If your primary focus is performance in a corrosive or high-purity system: PTFE's combination of low friction and chemical inertness prevents both contamination and material degradation.

- If your primary focus is predictable performance under load: You must analyze your application's specific pressure, velocity, and temperature to ensure PTFE will deliver the low-friction behavior you require.

Ultimately, understanding PTFE's complete profile allows you to design more efficient, durable, and reliable systems.

Summary Table:

| Key Property | Benefit for Low-Friction Applications |

|---|---|

| Lowest Coefficient of Friction | Creates an exceptionally slick, self-lubricating surface. |

| Chemical Inertness | Performs in corrosive environments where lubricants fail. |

| High-Temperature Stability | Maintains integrity and performance up to 327°C (621°F). |

| Non-Stick Surface | Prevents material buildup and contamination in high-purity systems. |

Need a reliable, low-friction solution for your critical components?

At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, bearings, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your parts deliver unparalleled performance, even in the most demanding dry-running or corrosive environments.

Leverage our custom fabrication services, from prototypes to high-volume orders, to solve your unique engineering challenges. Contact our team today to discuss your application and receive a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F