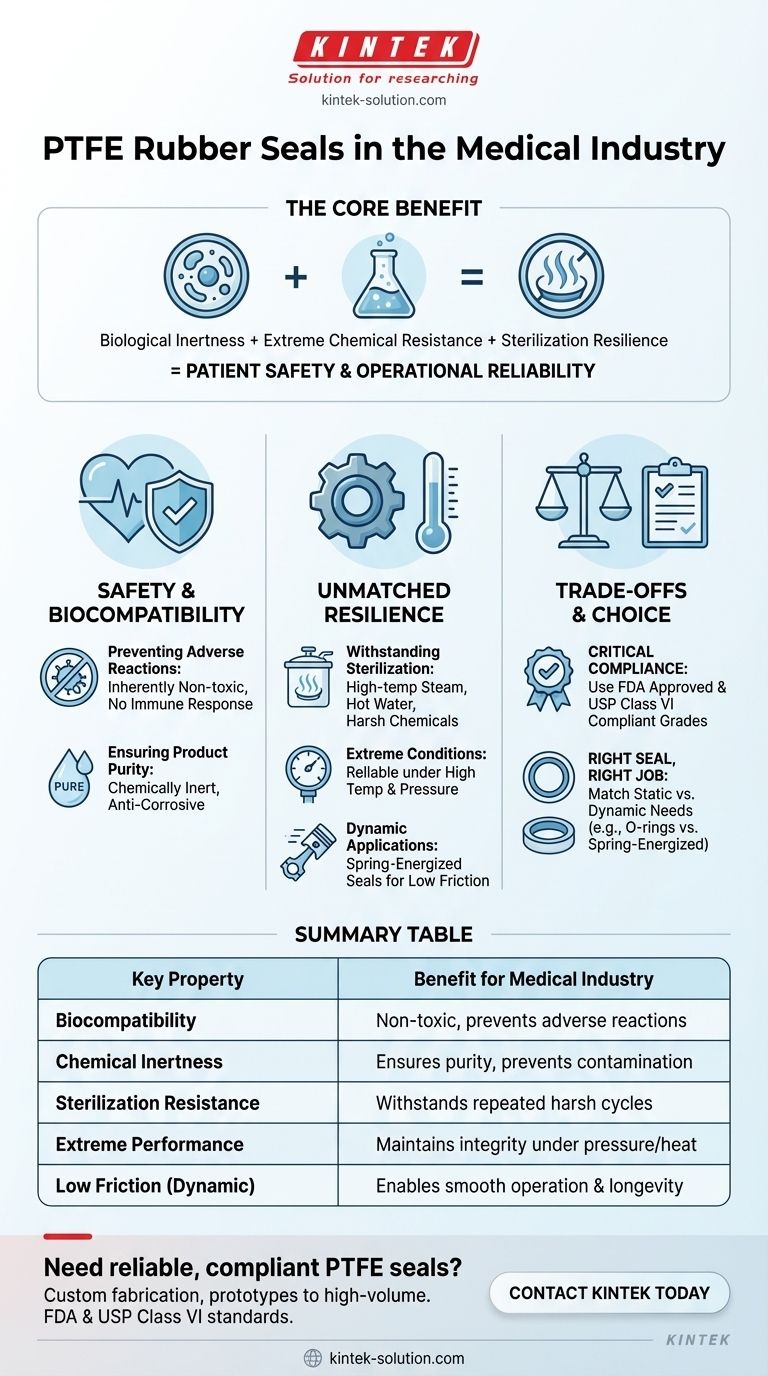

At its core, the suitability of Polytetrafluoroethylene (PTFE) for medical seals stems from a powerful combination of biological inertness, extreme chemical resistance, and the ability to withstand harsh sterilization processes. This unique blend of properties ensures both patient safety and the operational reliability of critical medical and pharmaceutical equipment.

The central reason PTFE is trusted in the medical industry is its non-reactive nature. It will not react with the human body, contaminate sensitive drugs, or degrade when subjected to the aggressive sterilization methods required to maintain a sterile environment.

The Foundation of Safety: Biocompatibility and Inertness

The primary concern in any medical application is patient safety. PTFE's fundamental chemical makeup provides an unparalleled level of assurance in this critical area.

Preventing Adverse Reactions

Biocompatibility is the most crucial property for any material that may come into contact with the human body. PTFE is inherently biocompatible, meaning it is non-toxic and does not provoke an immune response.

This ensures that seals used in medical devices, implants, or fluid paths do not leach harmful substances or cause adverse reactions, directly protecting the patient.

Ensuring Product Purity

In pharmaceutical manufacturing and laboratory settings, maintaining the purity of drugs and chemical agents is paramount. PTFE is chemically inert, meaning it is non-reactive and anti-corrosive.

This property makes it the ideal material for sealing containers and pipes that handle highly sensitive or corrosive chemicals, guaranteeing that the seal itself does not contaminate the final product.

Unmatched Resilience in Sterile Environments

Medical equipment must not only be safe but also robust enough to function reliably after repeated, aggressive cleaning and sterilization cycles.

Withstanding Aggressive Sterilization

Sterility is non-negotiable in the medical field. PTFE seals are exceptionally resistant to common sterilization methods, including high-temperature steam, hot water, and a wide range of harsh chemicals.

This resilience ensures the seal maintains its structural integrity and sealing capability through repeated Clean-in-Place (CIP) and sterilization cycles, which would degrade many other materials.

Performing Under Extreme Conditions

Medical devices such as ventilators and anesthesia machines often operate under demanding conditions. PTFE is valued for its ability to maintain its strength and form under extreme temperatures and pressures.

This ensures the long-term reliability of the seal, preventing leaks or failures in equipment where performance is a matter of life and death.

Excelling in Dynamic Applications

While simple O-rings are used in static applications, many medical devices have moving parts. For these dynamic uses, spring-energized PTFE seals are often employed.

These advanced seals offer very low friction, which ensures smooth operation and longevity in equipment like pumps and mechanical face seals, further enhancing device reliability.

Understanding the Trade-offs and Key Considerations

While PTFE is an exceptional material, its effective use in the medical industry requires careful selection and an understanding of regulatory standards.

The Critical Role of Compliance

Not all PTFE is suitable for medical use. It is essential to specify grades that meet stringent regulatory requirements.

Look for materials that are FDA approved and, for more critical applications, USP Class VI compliant. These certifications provide formal validation of the material's biocompatibility and safety for medical and pharmaceutical use.

Choosing the Right Seal for the Job

The type of PTFE seal must match the application. A simple static seal might be sufficient for a container lid, but a dynamic application like a ventilator piston requires a more complex design, like a spring-energized seal, to manage friction and wear.

Making the Right Choice for Your Application

Selecting the correct PTFE seal is a critical decision that directly impacts safety, compliance, and device performance.

- If your primary focus is patient-contact devices: Prioritize USP Class VI compliant PTFE to guarantee the highest standard of biocompatibility.

- If your primary focus is pharmaceutical processing: Select a grade known for its extreme chemical inertness to prevent any risk of drug contamination.

- If your primary focus is dynamic equipment like pumps or ventilators: Specify spring-energized PTFE seals to ensure low friction, durability, and reliable performance over time.

Choosing PTFE for a medical application is a deliberate decision for uncompromising safety and reliability.

Summary Table:

| Key Property | Benefit for Medical Industry |

|---|---|

| Biocompatibility | Non-toxic, prevents adverse reactions with the human body |

| Chemical Inertness | Ensures purity of drugs and sensitive agents by preventing contamination |

| Sterilization Resistance | Withstands repeated steam, chemical, and high-temperature sterilization cycles |

| Extreme Condition Performance | Maintains integrity under high pressure and temperature in life-saving equipment |

| Low Friction (Dynamic Seals) | Enables smooth operation and longevity in pumps and ventilators |

Need reliable, compliant PTFE seals for your medical or pharmaceutical equipment? At KINTEK, we specialize in manufacturing high-precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures you get seals that meet FDA and USP Class VI standards for uncompromising safety and performance. Contact us today to discuss your specific requirements and let us provide a solution you can trust.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers