In essence, Polytetrafluoroethylene (PTFE) is ideal for chemical and pharmaceutical industries because of its extreme chemical inertness and inherent purity. It does not react with, corrode from, or contaminate the aggressive chemicals and sensitive products used in these environments. This unique combination of properties ensures both operational safety and final product integrity.

The core reason PTFE dominates in these critical sectors is not just one feature, but its unique fusion of chemical invulnerability, physical stability, and compliance with strict health regulations. It fundamentally minimizes the risk of contamination and equipment failure.

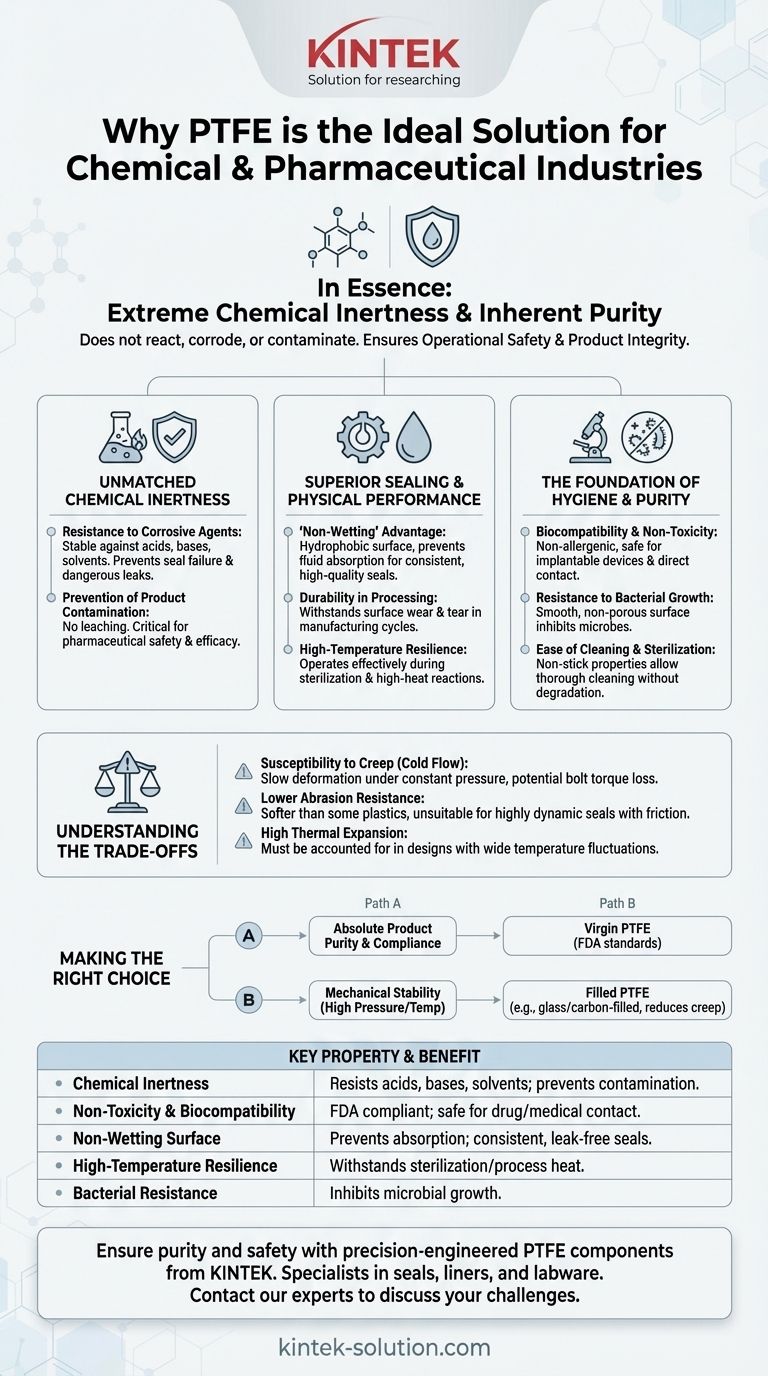

The Pillars of PTFE's Dominance

PTFE’s value is built on a few fundamental characteristics that directly address the primary challenges of the chemical and pharmaceutical industries: product purity, process safety, and regulatory compliance.

Unmatched Chemical Inertness

The defining feature of PTFE is its near-total resistance to chemical attack, which is essential when handling a wide range of substances.

Resistance to Corrosive Agents

PTFE gaskets and sheets remain stable even when exposed to the most aggressive acids, bases, and solvents. This prevents the material itself from degrading, which would otherwise lead to seal failure and dangerous leaks.

Prevention of Product Contamination

Because PTFE is chemically inert, it does not leach substances into the products it touches. This is non-negotiable in pharmaceutical manufacturing, where even trace amounts of contamination can compromise a drug's safety and efficacy.

Superior Sealing and Physical Performance

Beyond its chemical makeup, PTFE’s physical properties make it an exceptional material for creating and maintaining a secure seal.

The "Non-Wetting" Advantage

PTFE’s non-wetting, hydrophobic surface prevents process fluids from being absorbed into the gasket material. This ensures a consistent and high-quality seal, drastically reducing the potential for leaks over time.

Durability in Processing Environments

During drug and chemical manufacturing, components are subject to significant wear. PTFE withstands this surface wear and tear, maintaining its integrity and sealing capability through repeated operational cycles.

High-Temperature Resilience

PTFE can operate effectively across a wide range of temperatures, making it a reliable sealing solution in equipment that undergoes sterilization or involves high-temperature chemical reactions.

The Foundation of Hygiene and Purity

In environments where sterility is paramount, a material's surface properties are as important as its chemical composition.

Biocompatibility and Non-Toxicity

PTFE is non-toxic, non-allergenic, and biocompatible, meaning it does not cause adverse reactions in biological systems. This is critical for applications involving implantable devices or direct contact with pharmaceutical products.

Resistance to Bacterial Growth

The material's extremely smooth, non-porous surface offers no place for bacteria or other microbes to harbor and grow. This inherent resistance simplifies maintaining strict hygiene standards.

Ease of Cleaning and Sterilization

PTFE’s non-stick properties facilitate easy and thorough cleaning. It can withstand common sterilization processes without degrading, ensuring that equipment can be reliably prepared for each new batch.

Understanding the Trade-offs

No material is perfect, and being a trusted advisor means acknowledging limitations. While PTFE is an outstanding choice, its mechanical properties present specific trade-offs.

Susceptibility to Creep (Cold Flow)

Standard PTFE can slowly deform over time when subjected to constant pressure, a phenomenon known as creep or cold flow. This can lead to a loss of bolt torque and potential leaks in high-pressure applications.

Lower Abrasion Resistance

Compared to other engineering plastics, virgin PTFE is relatively soft and has lower resistance to abrasive media. This can make it unsuitable for highly dynamic seals that experience significant friction.

High Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. In systems with wide temperature fluctuations, this must be accounted for in the design to ensure the seal remains tight across the entire operating range.

Making the Right Choice for Your Application

Your specific goal will determine how you leverage PTFE's properties and mitigate its weaknesses.

- If your primary focus is absolute product purity and compliance: Virgin PTFE is the default choice, as its non-reactive and non-contaminating nature is unparalleled and meets strict FDA standards.

- If your primary focus is sealing highly aggressive chemicals: PTFE's chemical inertness makes it the most reliable option to prevent material degradation and ensure a long-lasting, leak-free seal.

- If your primary focus is mechanical stability under high pressure or temperature: Consider a filled PTFE (e.g., glass-filled or carbon-filled) to reduce creep and improve dimensional stability, though this may alter its chemical or compliance profile.

Ultimately, selecting PTFE is a strategic decision to prioritize chemical resilience and uncompromising product safety.

Summary Table:

| Key Property | Benefit for Chemical/Pharma Industries |

|---|---|

| Chemical Inertness | Resists aggressive acids, bases, and solvents; prevents contamination |

| Non-Toxicity & Biocompatibility | Meets FDA standards; safe for drug contact and medical devices |

| Non-Wetting Surface | Prevents fluid absorption; ensures consistent, leak-free seals |

| High-Temperature Resilience | Withstands sterilization and process heat cycles |

| Bacterial Resistance | Smooth, non-porous surface inhibits microbial growth |

Ensure the purity and safety of your chemical or pharmaceutical processes with precision-engineered PTFE components from KINTEK.

As specialists in high-performance PTFE seals, liners, and labware, we understand the critical demands of the semiconductor, medical, and laboratory industries. Whether you need standard parts or custom-fabricated solutions—from prototypes to high-volume orders—we prioritize precision and compliance to protect your products and equipment.

Contact our experts today to discuss how our PTFE components can solve your specific sealing challenges and enhance your operational reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications