In short, PTFE gaskets are an excellent choice for compressors because of their unique combination of properties. They simultaneously withstand high temperatures, resist chemical attack, and provide a low-friction, self-lubricating seal that enhances both durability and operational efficiency.

The core reason for PTFE's effectiveness is not a single attribute, but its holistic ability to solve the multiple, competing challenges present within a compressor: extreme heat, high pressure, constant friction, and potential exposure to corrosive media.

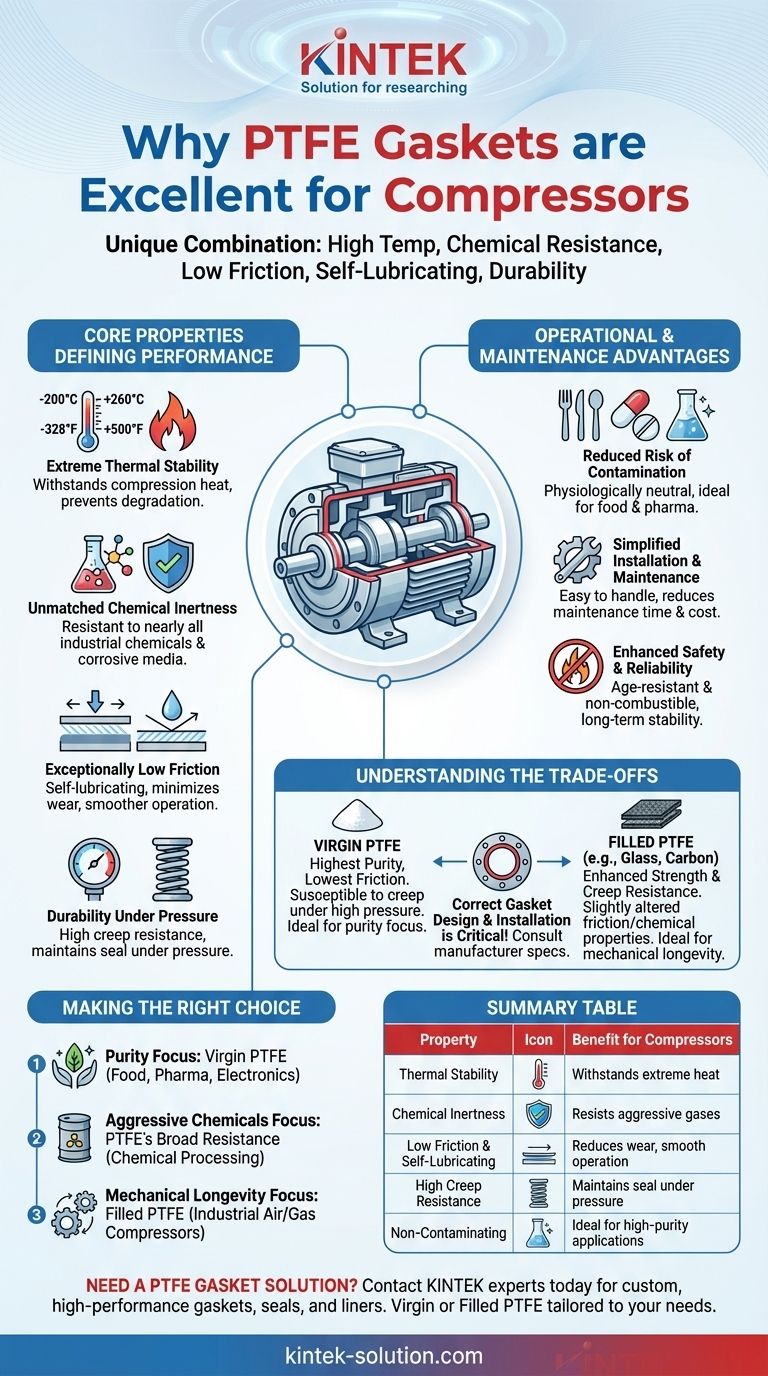

The Core Properties Defining PTFE's Performance

To understand why PTFE (Polytetrafluoroethylene) is so well-suited for compressors, we must examine its fundamental material characteristics. Each property directly addresses a specific stressor found in compression systems.

Extreme Thermal Stability

PTFE operates effectively across an exceptionally wide thermal range, typically from –200 °C to +260 °C (–328 °F to +500 °F).

This makes it highly resistant to the significant heat generated during the gas compression cycle, preventing material degradation and ensuring a consistent seal over time.

Unmatched Chemical Inertness

This material is resistant to nearly all industrial chemicals and media.

This property is critical for compressors that handle aggressive gases or operate in corrosive environments. It ensures the gasket will not swell, dissolve, or break down, preventing leaks and system failure.

Exceptionally Low Friction

PTFE has an exceptionally low coefficient of friction, making it a self-lubricating material.

This is a major advantage for components like piston rings, as it minimizes wear on moving parts and eliminates "stick-slip" effects. The result is smoother, more efficient, and quieter operation.

Durability Under Pressure

PTFE gaskets exhibit high creep resistance and can withstand high operational pressures without breaking.

This structural integrity ensures the gasket maintains its shape and sealing force, which is essential for the high-pressure differentials found in compressors.

Operational and Maintenance Advantages

Beyond its core material science, PTFE provides tangible benefits that simplify operations and reduce long-term costs.

Reduced Risk of Contamination

PTFE is physiologically neutral, non-contaminating, and odorless.

This makes it the default choice for applications in the food, beverage, and pharmaceutical industries, where media purity is non-negotiable.

Simplified Installation and Maintenance

The material's good adaptability and high elongation allow for easy molding, fitting, and installation.

Technicians find PTFE gaskets easy to handle during assembly and dismantling, which helps reduce maintenance time and associated labor costs.

Enhanced Safety and Reliability

PTFE is both age-resistant and non-combustible, contributing to a safer and more reliable system.

Its inherent stability ensures long-term performance without the material becoming brittle or failing unexpectedly, which is key to ensuring operational safety in industrial plants.

Understanding the Trade-offs

While highly effective, it is important to select the right type of PTFE for the application. No single material is a universal solution.

Virgin PTFE vs. Filled PTFE

Virgin PTFE offers the highest chemical purity and lowest friction. However, it can be susceptible to creep (cold flow) under high, sustained pressure.

To counteract this, filled PTFE grades are used. By adding materials like glass, carbon, or graphite, manufacturers significantly enhance the gasket's mechanical strength, rigidity, and resistance to creep, though this may slightly alter its chemical or frictional properties.

Correct Gasket Design is Critical

The effectiveness of a PTFE gasket is highly dependent on proper design and installation for the specific flange and pressure rating.

An improperly specified or installed gasket can lead to premature failure, regardless of the material's inherent strengths. Always consult the compressor manufacturer's specifications.

Making the Right Choice for Your Compressor

Your final decision should be guided by the most critical demand of your specific application.

- If your primary focus is purity and non-contamination: Virgin PTFE is the ideal choice for its inertness in food, pharmaceutical, or electronics manufacturing.

- If your primary focus is handling aggressive chemicals: PTFE's broad chemical resistance makes it the safest and most reliable option for chemical processing compressors.

- If your primary focus is mechanical longevity under high pressure: A filled PTFE gasket will provide the necessary creep resistance and durability for demanding industrial air or gas compressors.

By matching the material's strengths to your operational needs, you ensure your equipment runs safely, reliably, and efficiently.

Summary Table:

| Property | Benefit for Compressors |

|---|---|

| Thermal Stability (-200°C to +260°C) | Withstands extreme heat from compression cycles |

| Chemical Inertness | Resists aggressive gases and corrosive environments |

| Low Friction & Self-Lubricating | Reduces wear, minimizes stick-slip, and ensures smooth operation |

| High Creep Resistance | Maintains seal integrity under high pressure |

| Non-Contaminating | Ideal for food, pharmaceutical, and high-purity applications |

Need a PTFE gasket solution for your compressor?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom gaskets, seals, and liners. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our precision production ensures your compressor operates with maximum reliability and efficiency.

We offer custom fabrication from prototypes to high-volume orders, tailoring the material (virgin or filled PTFE) to your specific needs for chemical resistance, pressure handling, and purity.

Contact our experts today to discuss your application and receive a tailored solution that enhances your compressor's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions