The remarkable durability of PTFE bushes in extreme conditions stems from the material's inherent molecular stability, which provides exceptional resistance to a wide range of thermal, pressure, and environmental stressors. This allows PTFE to maintain its structural integrity and performance characteristics in applications where most other materials would degrade and fail.

PTFE's resilience is not about brute strength, but about its profound chemical and thermal stability. It remains fundamentally unchanged across an exceptionally wide operational window, making it a reliable choice for the most demanding and critical environments.

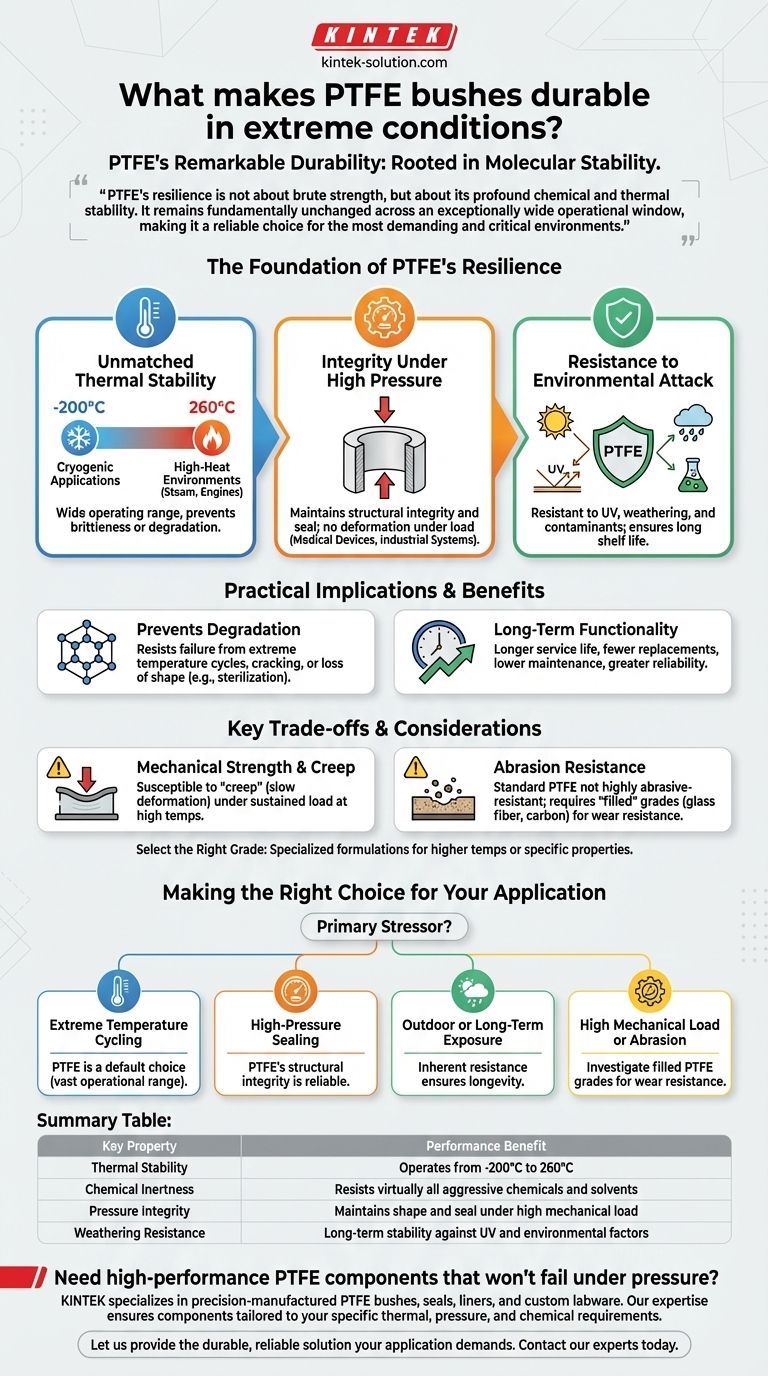

The Foundation of PTFE's Resilience

To understand why PTFE (Polytetrafluoroethylene) bushes are so durable, we must look at their core material properties. These characteristics work together to ensure consistent performance under punishing conditions.

Unmatched Thermal Stability

PTFE exhibits an incredibly wide operating temperature range, typically from -200°C to 260°C (-328°F to 500°F).

This makes it one of the few materials suitable for both cryogenic applications and high-heat environments like steam systems or high-powered engines. It will not become brittle in extreme cold or degrade in high heat, ensuring it maintains its shape and function.

Integrity Under High Pressure

Beyond temperature, PTFE components maintain their structural integrity under significant pressure.

This quality is critical in applications like medical devices or industrial systems where the material must not deform or fail under load, ensuring a reliable seal and consistent mechanical performance.

Resistance to Environmental Attack

PTFE is highly resistant to weathering, UV radiation, and environmental contaminants.

This means that even with long-term exposure to harsh weather or challenging industrial settings, the material will not degrade. This results in a long shelf life and predictable, long-lasting functionality.

Understanding the Practical Implications

These inherent properties translate directly into tangible performance benefits that define PTFE's reputation for durability.

How Stability Prevents Degradation

The chemical and thermal stability of PTFE means it resists common forms of material failure. It will not crack, lose its shape, or lose its core properties when subjected to the stress of extreme temperature cycles, such as those found in pharmaceutical sterilization processes.

Ensuring Long-Term Functionality

This inherent durability leads to a significantly longer service life compared to many other materials. For engineers and designers, this means fewer replacements, lower maintenance costs, and greater reliability in critical systems where failure is not an option.

Key Trade-offs and Considerations

While exceptionally stable, PTFE is not the ideal solution for every mechanical challenge. Understanding its limitations is key to using it effectively.

Mechanical Strength and Creep

Compared to metals or harder plastics, PTFE is a relatively soft material. Under a sustained mechanical load, especially at higher temperatures, it can be susceptible to "creep" or cold flow, a slow and permanent deformation.

Abrasion Resistance

Standard PTFE is not highly resistant to abrasion from sharp or rough particles. For applications involving abrasive media, "filled" grades of PTFE, which include additives like glass fiber or carbon, are often required to enhance wear resistance.

The Importance of Grade Selection

Not all PTFE is created equal. Specialized formulations, such as medical-grade PTFE, may be engineered to withstand even higher temperatures (over 300°C) or offer other enhanced properties. Always match the specific grade to your application's demands.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the primary stressor in your operational environment.

- If your primary focus is extreme temperature cycling: PTFE is a default choice due to its vast operational range from cryogenic lows to high-temperature highs.

- If your primary focus is high-pressure sealing: PTFE’s ability to maintain its structural integrity without deforming makes it a highly reliable option.

- If your primary focus is outdoor or long-term exposure: Its inherent resistance to weathering and environmental contaminants ensures predictable longevity.

- If your primary focus is high mechanical load or abrasion: You should investigate filled PTFE grades to gain the necessary wear resistance and dimensional stability.

Ultimately, PTFE's unique combination of stability and resilience makes it a foundational material for ensuring reliability in the world's harshest operating conditions.

Summary Table:

| Key Property | Performance Benefit |

|---|---|

| Thermal Stability | Operates from -200°C to 260°C (-328°F to 500°F) |

| Chemical Inertness | Resists virtually all aggressive chemicals and solvents |

| Pressure Integrity | Maintains shape and seal under high mechanical load |

| Weathering Resistance | Long-term stability against UV and environmental factors |

Need high-performance PTFE components that won't fail under pressure?

KINTEK specializes in precision-manufactured PTFE bushes, seals, liners, and custom labware designed to excel in the most extreme conditions. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a component perfectly tailored to your specific thermal, pressure, and chemical requirements.

Let us provide the durable, reliable solution your application demands.

Contact our experts today to discuss your project and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability