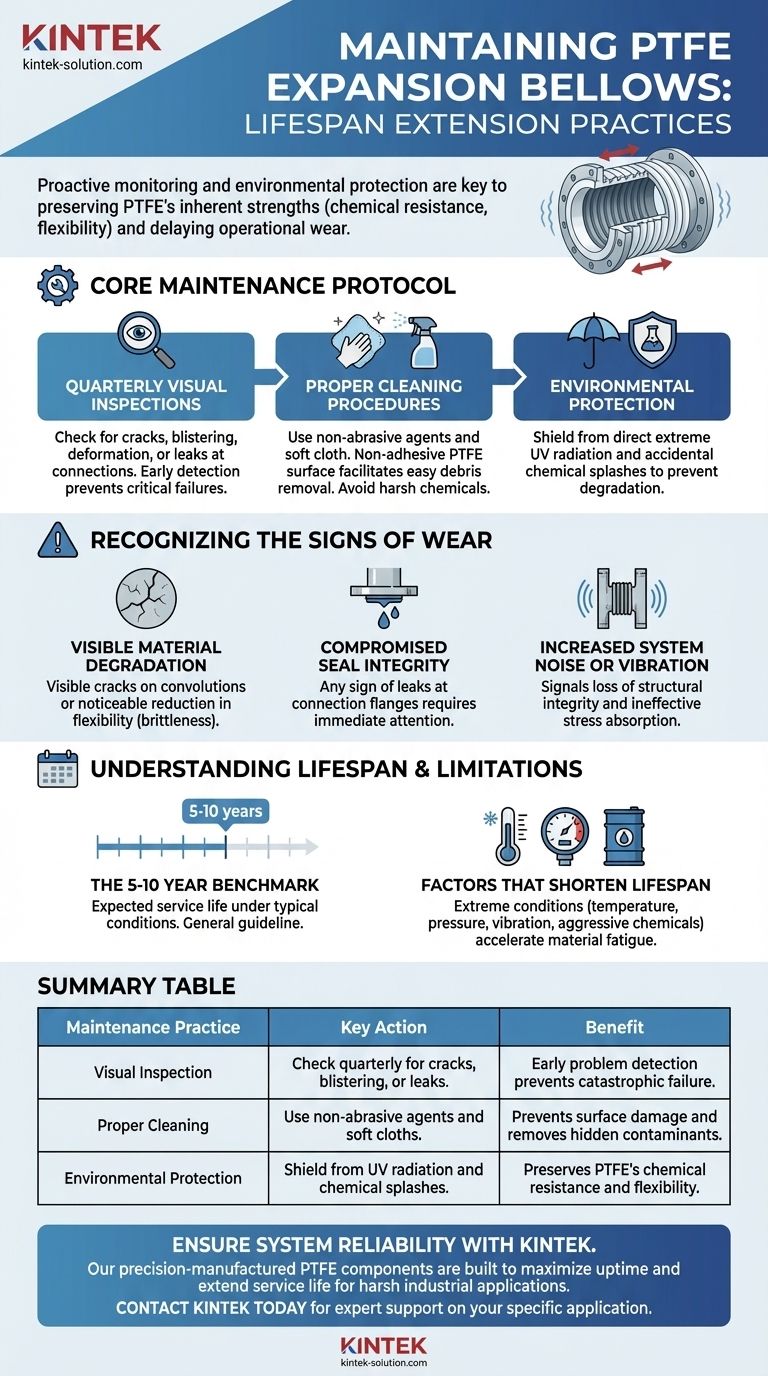

To extend the lifespan of PTFE expansion bellows, the most effective maintenance practices are a combination of proactive monitoring and environmental protection. This involves conducting quarterly visual inspections for damage, cleaning the surface with non-abrasive agents, and shielding the bellows from excessive UV radiation and chemical splashes.

The core principle is not just to perform maintenance but to create an environment where the inherent strengths of PTFE—its chemical resistance and flexibility—are preserved, delaying the natural wear caused by operational stress and exposure.

Why Proactive Maintenance is Crucial for PTFE Bellows

PTFE expansion bellows are engineered to solve a difficult problem: protecting pipeline systems from the stresses of thermal expansion, vibration, and misalignment. Understanding their role clarifies why maintenance is so critical.

Accommodating Constant System Stress

Expansion bellows act as the flexible "joint" in a rigid system. They absorb movement and vibration that would otherwise concentrate stress on pipes, flanges, and connected equipment, preventing premature failure.

Leveraging PTFE's Inherent Strengths

The choice of PTFE (polytetrafluoroethylene) is deliberate. Its remarkable chemical resistance makes it suitable for a vast range of corrosive media, while its non-adhesive surface naturally resists material buildup, simplifying cleaning.

The Core Maintenance Protocol

A simple, consistent maintenance routine is the key to maximizing the service life of these components.

Quarterly Visual Inspections

Regular inspection is the most effective way to catch problems early. At least once per quarter, carefully examine the bellow's surface for any signs of cracks, blistering, or deformation. Pay close attention to the connection points for any evidence of leaks.

Proper Cleaning Procedures

Over time, dust and debris can accumulate on the bellow's surface. This buildup can hide underlying issues and, in some cases, abrade the material.

Clean the bellows using only non-abrasive agents and a soft cloth or low-pressure water spray. The non-adhesive nature of PTFE means that most contaminants will be easy to remove without harsh chemicals or scrubbing.

Environmental Protection

While PTFE is highly durable, it is not indestructible. Prolonged, direct exposure to extreme UV radiation can cause the material to degrade over time. If the bellows are installed outdoors, consider using a simple shield or cover.

Similarly, protect the bellows from accidental chemical splashes of substances they are not rated to handle.

Recognizing the Signs of Wear

Even with perfect maintenance, every component has a finite lifespan. Knowing the warning signs allows for planned replacement instead of costly emergency shutdowns.

Visible Material Degradation

The most obvious indicators of wear are visible cracks on the surface of the convolutions. Another sign is a noticeable reduction in flexibility, which indicates the material is becoming brittle.

Compromised Seal Integrity

Any sign of a leak at the connection flanges means the seal has been compromised. This requires immediate attention, as it can indicate a critical failure is imminent.

Increased System Noise or Vibration

If the overall system begins to exhibit more noise or vibration than usual, it can mean the expansion bellow is no longer effectively absorbing stress. This signals it has lost its structural integrity and needs to be replaced.

Understanding Lifespan and Limitations

It is essential to have realistic expectations for the service life of any flexible component.

The 5-10 Year Benchmark

Under typical operating conditions, a well-maintained PTFE expansion bellow can be expected to last between 5 and 10 years. This is a general guideline, not a guarantee.

Factors That Shorten Lifespan

This lifespan can be significantly reduced by extreme conditions. Constant operation at the upper limits of temperature or pressure, severe and continuous vibration, or frequent exposure to aggressive chemicals will accelerate material fatigue and lead to a shorter service life.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your operational priorities.

- If your primary focus is maximizing uptime in a critical system: Implement a rigorous, documented quarterly inspection schedule and plan for proactive replacement based on the manufacturer's recommendations and your operating conditions.

- If your primary focus is extending asset life in standard conditions: Consistent cleaning and proactive shielding from UV and chemical exposure are your most cost-effective tools for achieving the upper end of the component's expected lifespan.

Ultimately, viewing these components as valuable assets that require proactive care is the key to ensuring their long-term reliability.

Summary Table:

| Maintenance Practice | Key Action | Benefit |

|---|---|---|

| Visual Inspection | Check quarterly for cracks, blistering, or leaks. | Early problem detection prevents catastrophic failure. |

| Proper Cleaning | Use non-abrasive agents and soft cloths. | Prevents surface damage and removes hidden contaminants. |

| Environmental Protection | Shield from UV radiation and chemical splashes. | Preserves PTFE's chemical resistance and flexibility. |

Ensure your system's reliability with high-performance PTFE components from KINTEK.

Our precision-manufactured PTFE expansion bellows, seals, and liners are engineered for the harsh conditions of the semiconductor, medical, laboratory, and industrial sectors. Whether you need a custom prototype or a high-volume order, our components are built to maximize uptime and extend service life.

Contact KINTEK today to discuss your specific application and receive expert support.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials