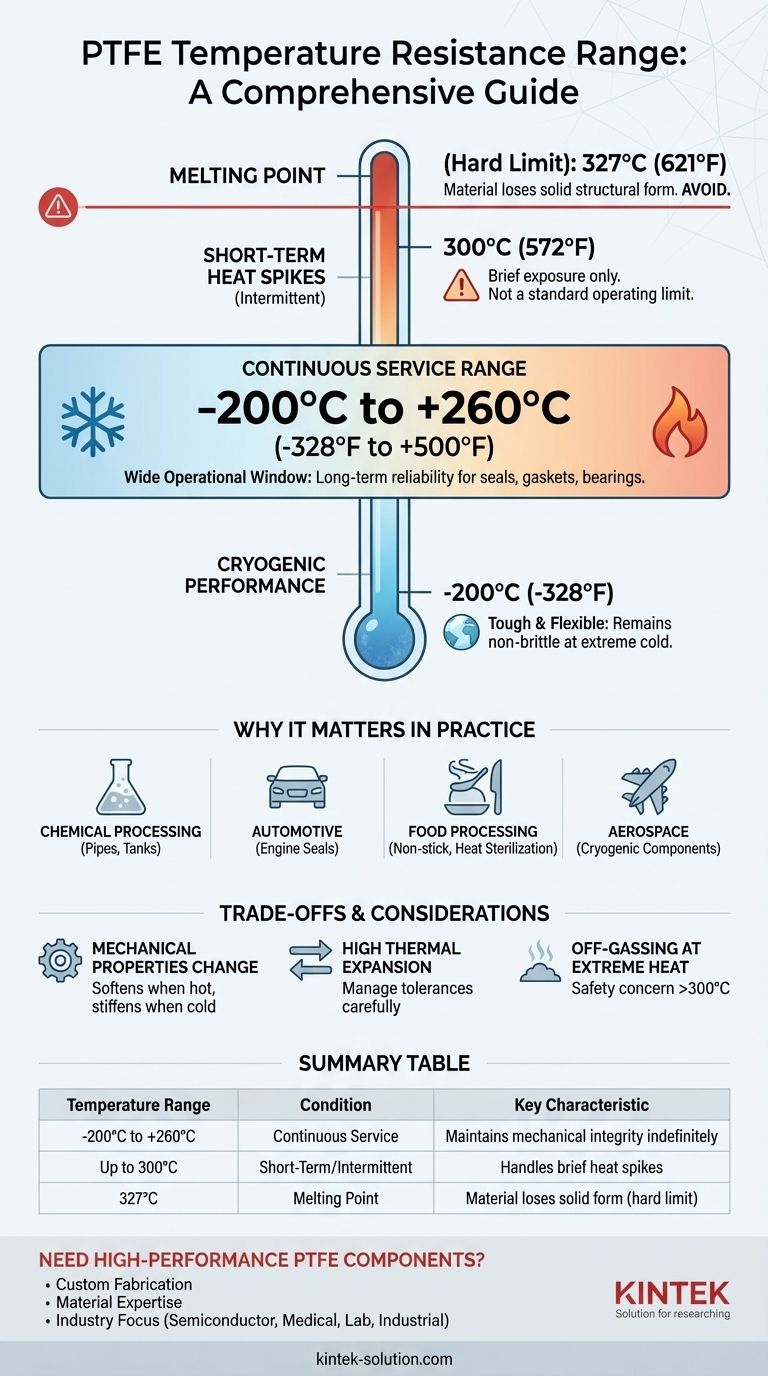

In short, PTFE's standard continuous service temperature ranges from -200°C to +260°C (-328°F to +500°F). This exceptionally wide operational window is one of its most defining characteristics, allowing it to perform reliably in conditions where most other plastics would fail, from cryogenic freezing to high-heat industrial applications. Some grades can even handle brief intermittent exposure to temperatures as high as 300°C (572°F).

The key takeaway is not just the numbers, but what they represent: PTFE offers elite thermal stability across a vast spectrum. It uniquely resists degradation from both extreme heat and extreme cold, making it a specialized material for the most demanding engineering challenges.

Deconstructing PTFE's Thermal Performance

To properly leverage PTFE, you must understand the nuances behind its temperature ratings. These figures are not arbitrary; they define the boundaries of the material's structural and chemical integrity.

The Continuous Service Temperature

The most critical range to remember is -200°C to +260°C (-328°F to +500°F). Within this window, PTFE can operate indefinitely without any significant loss of its essential mechanical properties. This is the range designers rely on for long-term reliability in parts like seals, gaskets, and bearings.

Handling Short-Term Heat Spikes

For brief periods, PTFE can withstand temperatures higher than its continuous rating. Many sources indicate it can handle intermittent exposure up to 290°C or even 300°C (554°F to 572°F). This tolerance is useful in applications where temperature fluctuations or short heat cycles are expected, but it should not be considered the standard operating limit.

The Melting Point: A Hard Limit

PTFE's melting point is approximately 327°C (621°F). At this temperature, the material undergoes a phase change and loses its solid structural form. It's crucial to distinguish the service temperature from the melting point—operating a component anywhere near the melting point is not viable.

Performance at Cryogenic Temperatures

What makes PTFE remarkable is its performance at the low end of the spectrum. Down to -200°C, it remains tough and flexible. Unlike many polymers that become extremely brittle and shatter at such low temperatures, PTFE maintains its utility, making it a go-to choice for cryogenic applications.

Why This Range Matters in Practice

The thermal stability of PTFE is not just an academic data point; it's the primary reason it is selected over more common and less expensive plastics for critical components.

A Clear Advantage Over Other Polymers

Standard plastics like Polypropylene or ABS have a much narrower thermal window and would quickly deform or degrade at the temperatures PTFE handles routinely. This makes PTFE essential in environments where material failure is not an option.

High-Temperature Applications

The ability to withstand +260°C continuously makes PTFE ideal for demanding industries. You will find it in chemical processing (linings for pipes and tanks), automotive (seals in high-temperature engine compartments), and food processing (non-stick coatings and components that undergo heat sterilization).

Cryogenic and Low-Temperature Applications

The material's resilience at -200°C is critical for aerospace components exposed to the cold of high altitudes or space. It is also used for seals and valves in equipment that handles liquified gases like liquid nitrogen.

Understanding the Trade-offs and Considerations

While its thermal range is impressive, designing with PTFE requires acknowledging a few practical realities.

Mechanical Properties Are Not Static

PTFE's physical properties change with temperature. As it gets hotter, it becomes softer and more susceptible to creep (deformation under load). As it gets colder, it becomes stiffer. Engineers must account for these changes in their design calculations.

High Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion. This means it expands and contracts significantly with temperature changes. In designs with tight tolerances, this must be carefully managed to avoid component failure.

Off-Gassing at Extreme Heat

When heated well above its recommended service temperature (approaching 300°C and beyond), PTFE will begin to decompose and release fumes. This is a critical safety consideration, particularly in poorly ventilated areas.

Making the Right Choice for Your Goal

Selecting a material depends entirely on the demands of the application. Understanding PTFE's thermal profile allows you to place it correctly.

- If your primary focus is high-heat industrial processes: PTFE's +260°C continuous rating provides a reliable safety margin for gaskets, insulators, and linings where other polymers would fail.

- If your primary focus is cryogenic or extreme cold: PTFE's ability to remain functional and non-brittle down to -200°C is its key advantage for aerospace, research, and liquefied gas systems.

- If your application involves wide temperature swings: You must design with PTFE's thermal expansion in mind, ensuring tolerances are sufficient to prevent binding or stress fractures.

By understanding this complete thermal profile, you can confidently leverage PTFE's unique capabilities to solve extreme engineering challenges.

Summary Table:

| Temperature Range | Condition | Key Characteristic |

|---|---|---|

| -200°C to +260°C | Continuous Service | Maintains mechanical integrity indefinitely |

| Up to 300°C | Short-Term/Intermittent | Handles brief heat spikes |

| 327°C | Melting Point | Material loses solid form (hard limit) |

Need High-Performance PTFE Components for Extreme Environments?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—that deliver reliable performance across the full thermal spectrum, from cryogenic conditions to high-heat processes.

We provide:

- Custom Fabrication: From prototypes to high-volume orders.

- Material Expertise: Ensuring your components meet exact thermal and mechanical requirements.

- Industry Focus: Serving the semiconductor, medical, laboratory, and industrial sectors.

Let us help you solve your most demanding engineering challenges. Contact our team today to discuss your specific application needs!

Visual Guide

Related Products

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- What are the unique properties of PTFE that make it commercially valuable? Unlock Unmatched Performance

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- In which industries is PTFE commonly used? Key Applications for Chemical & Thermal Resistance

- What are the common characteristics of Teflon? Unlocking Extreme Chemical and Thermal Resistance

- Why is chemical compatibility important when choosing a PTFE-coated septum? Avoid Sample Contamination and Data Loss