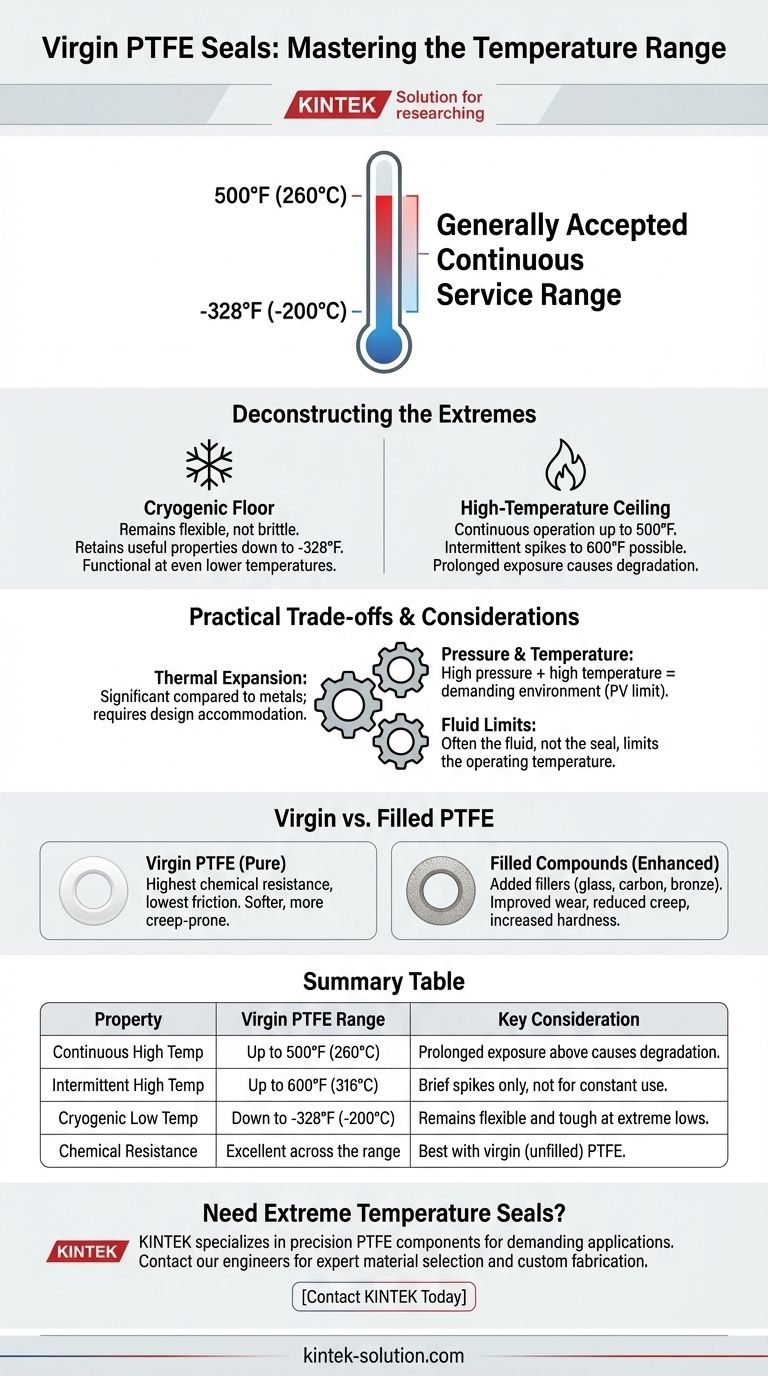

For virgin PTFE seals, the generally accepted continuous service temperature range is from approximately -328°F to 500°F (-200°C to 260°C). While some sources may cite even lower cryogenic limits near -425°F, the -328°F figure represents a widely supported threshold where the material retains its useful mechanical properties without becoming brittle.

The key takeaway is not a single number, but a principle: PTFE's exceptional temperature tolerance is a baseline. The actual effective range in your application is determined by the interplay of pressure, mechanical stress, and the operational limits of the entire system.

Deconstructing the Temperature Range

Understanding what happens at the extremes of this range is critical for reliable seal design and material selection. The published numbers represent the temperatures at which the material itself remains stable.

The High-Temperature Ceiling

The upper limit of 500°F (260°C) is a well-established threshold for continuous operation. At this temperature, virgin PTFE maintains its excellent chemical resistance and low-friction characteristics.

Some specialized compounds can handle brief, intermittent spikes up to 600°F (316°C), but prolonged exposure above the continuous limit will lead to accelerated degradation and off-gassing.

The Cryogenic Floor

PTFE is remarkable for its performance at extremely low temperatures. It does not become brittle in the same way elastomers do, remaining tough and flexible.

While a conservative lower limit is often stated as -328°F (-200°C), the material remains functional at even colder temperatures, making it a default choice for many cryogenic applications.

Continuous vs. Intermittent Exposure

It is crucial to distinguish between a seal's ability to operate continuously versus its capacity to survive brief temperature excursions.

A seal rated for 500°F can operate at that temperature for its entire service life. A higher intermittent rating implies it can survive short periods at that temperature without catastrophic failure, but it is not designed for constant use under those conditions.

Virgin PTFE vs. Filled Compounds

The term "PTFE" often covers a family of materials. The distinction between virgin and filled grades is essential for performance.

What is Virgin PTFE?

Virgin PTFE is pure, 100% Polytetrafluoroethylene with no added fillers. It offers the highest chemical resistance and lowest coefficient of friction. However, it is softer and more susceptible to creep (cold flow) under load.

The Role of Fillers

Fillers such as glass, carbon, or bronze are added to PTFE to enhance specific mechanical properties. They are used to improve wear resistance, reduce creep, and increase hardness.

While these fillers primarily modify mechanical behavior, they can slightly alter the material's thermal properties, but the fundamental temperature range remains broadly similar to that of virgin PTFE.

Understanding the Practical Trade-offs

A material's data sheet temperature range is only part of the story. Real-world performance is governed by several interacting factors.

Thermal Expansion

PTFE has a relatively high coefficient of thermal expansion compared to metals. This means it expands and contracts significantly with temperature changes. This property must be accounted for in the seal design to prevent failure at temperature extremes.

Pressure and Temperature Interdependence

The maximum operating temperature is not independent of system pressure. High pressure and high temperature combined create a much more demanding environment for a seal than either condition alone. This relationship is often characterized by a material's "PV limit" (Pressure-Velocity).

The Influence of System Fluids

In many cases, the system's operating temperature is limited by the fluid, not the seal. For example, while a PTFE seal can easily handle 450°F, many hydraulic fluids begin to oxidize and break down well below 200°F, dictating a lower practical operating temperature.

Making the Right Choice for Your Application

Use the material's capabilities as a guide to meet your specific operational goals.

- If your primary focus is extreme high-temperature stability: Target a grade rated for 500°F (260°C) continuous service, and consider a filled compound if high pressure or wear resistance is also a concern.

- If your primary focus is cryogenic performance: Virgin PTFE is an excellent choice, remaining functional down to -328°F (-200°C) and beyond, but ensure your hardware design accommodates its thermal contraction.

- If your primary focus is broad chemical resistance: Virgin PTFE offers the most robust performance across the widest range of chemicals within its temperature limits.

Ultimately, selecting the correct seal requires matching the unique properties of PTFE to the complete set of demands in your specific application.

Summary Table:

| Property | Virgin PTFE Range | Key Consideration |

|---|---|---|

| Continuous High Temp | Up to 500°F (260°C) | Prolonged exposure above this limit causes degradation. |

| Intermittent High Temp | Up to 600°F (316°C) | Brief spikes are possible, but not for constant use. |

| Cryogenic Low Temp | Down to -328°F (-200°C) | Remains flexible and tough at extreme lows. |

| Chemical Resistance | Excellent across the range | Best with virgin (unfilled) PTFE. |

Need a PTFE Seal for Extreme Temperatures?

Understanding the temperature range is just the first step. The right seal must also handle your specific pressure, chemical, and mechanical stress requirements.

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Expert Material Selection: Guidance on virgin vs. filled PTFE compounds to optimize performance.

- Precision Production: Seals built to exact specifications for reliable operation.

- Custom Fabrication: From initial prototypes to high-volume production runs.

Let our engineers help you specify the perfect seal for your application. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is the overall operating temperature range for PTFE seals, gaskets, and O-rings? Achieve Sealing Integrity from -200°C to +260°C

- What are the two temperature extremes discussed for PTFE seals? Maximize Performance from Cryogenic to High-Heat

- What are the benefits of using PTFE seals? Unmatched Chemical & Temperature Resistance

- What are the key properties of PTFE that make it suitable for seals? Unlock Reliability in Extreme Conditions

- What are the benefits of PTFE seals in terms of prototyping and production? Accelerate R&D and Ensure Elite Performance