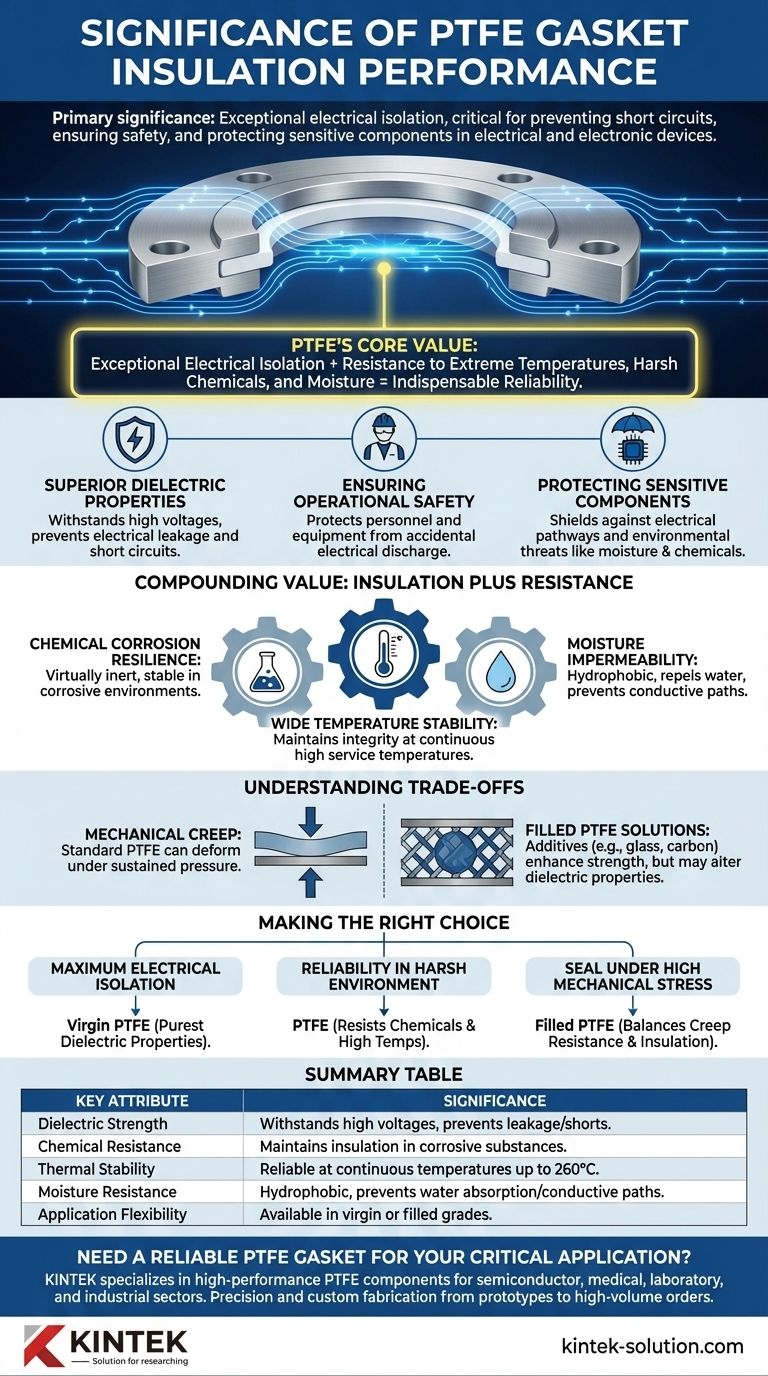

The primary significance of PTFE's insulation performance lies in its exceptional ability to isolate electrical current, which is critical for preventing short circuits, ensuring operational safety, and protecting sensitive components. This makes Polytetrafluoroethylene (PTFE) gaskets an essential material in a vast range of electrical equipment and electronic devices where both sealing and electrical isolation are required.

While many materials can insulate, PTFE's true value comes from its ability to provide exceptional electrical isolation while simultaneously resisting extreme temperatures, harsh chemicals, and moisture. This unique combination makes it an indispensable material for ensuring reliability in demanding electrical applications.

Why PTFE is a Premier Electrical Insulator

PTFE, commonly known by the brand name Teflon, is not just a good insulator; its properties make it one of the most reliable choices for high-stakes electrical and electronic systems.

Superior Dielectric Properties

A material's dielectric strength measures its ability to withstand a strong electric field without breaking down and conducting electricity. PTFE possesses excellent dielectric properties, meaning it can handle high voltages without failure.

This quality is crucial for preventing electrical leakage and short circuits between conductive parts, which could otherwise lead to equipment damage or failure.

Ensuring Operational Safety

The most fundamental role of an electrical insulator is safety. By effectively isolating current, PTFE gaskets prevent accidental electrical discharge.

This protects not only the equipment itself but also the personnel who operate and maintain it, making it a cornerstone of safe system design.

Protecting Sensitive Components

Modern electronics are often highly sensitive. PTFE gaskets shield these components from damage by preventing unintended electrical pathways from forming.

Furthermore, they protect against environmental threats like moisture and chemicals, which can compromise a component's electrical integrity and lead to premature failure.

The Compounding Value: Insulation Plus Resistance

PTFE's significance skyrockets when you consider that its elite insulation performance does not exist in a vacuum. It is paired with world-class resistance to other common points of industrial failure.

Resilience Against Chemical Corrosion

In many industrial settings, electrical components are exposed to corrosive chemicals. Many insulating materials would degrade under such conditions, losing their ability to isolate current.

PTFE is virtually inert and resistant to nearly all chemicals, ensuring that its electrical insulation properties remain stable and reliable over its entire service life.

Stability Across Wide Temperature Ranges

High electrical currents often generate significant heat. PTFE gaskets maintain their structural integrity and insulating capabilities at continuous service temperatures up to 500°F (260°C).

This thermal stability prevents the material from melting, deforming, or losing its dielectric strength in high-temperature operating environments.

Impermeability to Moisture

Moisture is a primary enemy of electrical systems, as it can create conductive paths and cause short circuits. PTFE is hydrophobic, meaning it repels water.

This inherent resistance to moisture ensures that the gasket will not absorb water and compromise the electrical isolation it is designed to provide.

Understanding the Trade-offs

While PTFE is a superior material, no single solution is perfect for every scenario. Acknowledging its characteristics is key to proper application.

Mechanical Properties and Creep

Standard PTFE can be subject to "creep" or "cold flow," where the material slowly deforms over time under sustained mechanical pressure. In high-pressure sealing applications, this can eventually compromise the seal.

This is a critical design consideration, especially for gaskets that must maintain a tight seal under a constant compressive load.

Material Selection: Virgin vs. Filled PTFE

To counter mechanical limitations like creep, manufacturers produce modified or "filled" PTFE gaskets by adding materials like glass, carbon, or graphite.

These fillers enhance mechanical strength and dimensional stability. However, it is crucial to understand that these additives can sometimes alter the material's dielectric properties, requiring careful selection based on the specific electrical and mechanical demands of the application.

Making the Right Choice for Your Goal

Selecting the appropriate gasket requires matching the material's strengths to your primary objective.

- If your primary focus is maximum electrical isolation: Virgin PTFE is often the best choice, as it offers the purest dielectric properties without additives that could affect performance.

- If your primary focus is reliability in a harsh environment: PTFE is an ideal candidate, as its insulation performance will not degrade when exposed to aggressive chemicals or high temperatures.

- If your primary focus is maintaining a seal under high mechanical stress: Consider a filled or modified PTFE gasket that balances enhanced creep resistance with the necessary electrical insulation for your application.

Ultimately, PTFE's electrical insulation is not just a single feature but a cornerstone of its unmatched reliability in complex and demanding environments.

Summary Table:

| Key Attribute | Significance of PTFE Insulation |

|---|---|

| Dielectric Strength | Withstands high voltages to prevent electrical leakage and short circuits. |

| Chemical Resistance | Maintains insulating properties when exposed to corrosive substances. |

| Thermal Stability | Performs reliably at continuous temperatures up to 260°C (500°F). |

| Moisture Resistance | Hydrophobic nature prevents water absorption and conductive paths. |

| Application Flexibility | Available in virgin (pure insulation) or filled (enhanced strength) grades. |

Need a reliable PTFE gasket for your critical application?

KINTEK specializes in manufacturing high-performance PTFE components, including seals and gaskets, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your components benefit from superior electrical insulation combined with exceptional chemical and thermal resistance.

We prioritize precision and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your project requirements and discover how our PTFE solutions can enhance the safety and reliability of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications