In ideal conditions, a solid Polytetrafluoroethylene (PTFE) O-ring has a virtually unlimited shelf life. Its unique chemical structure makes it exceptionally stable and resistant to the environmental factors that typically degrade other materials over time, such as oxidation, UV radiation, or moisture.

The core distinction to understand is between solid PTFE and PTFE-coated O-rings. While solid PTFE is inert and does not degrade, the shelf life and performance of a PTFE-coated O-ring are dictated entirely by its underlying elastomeric base material, not the coating.

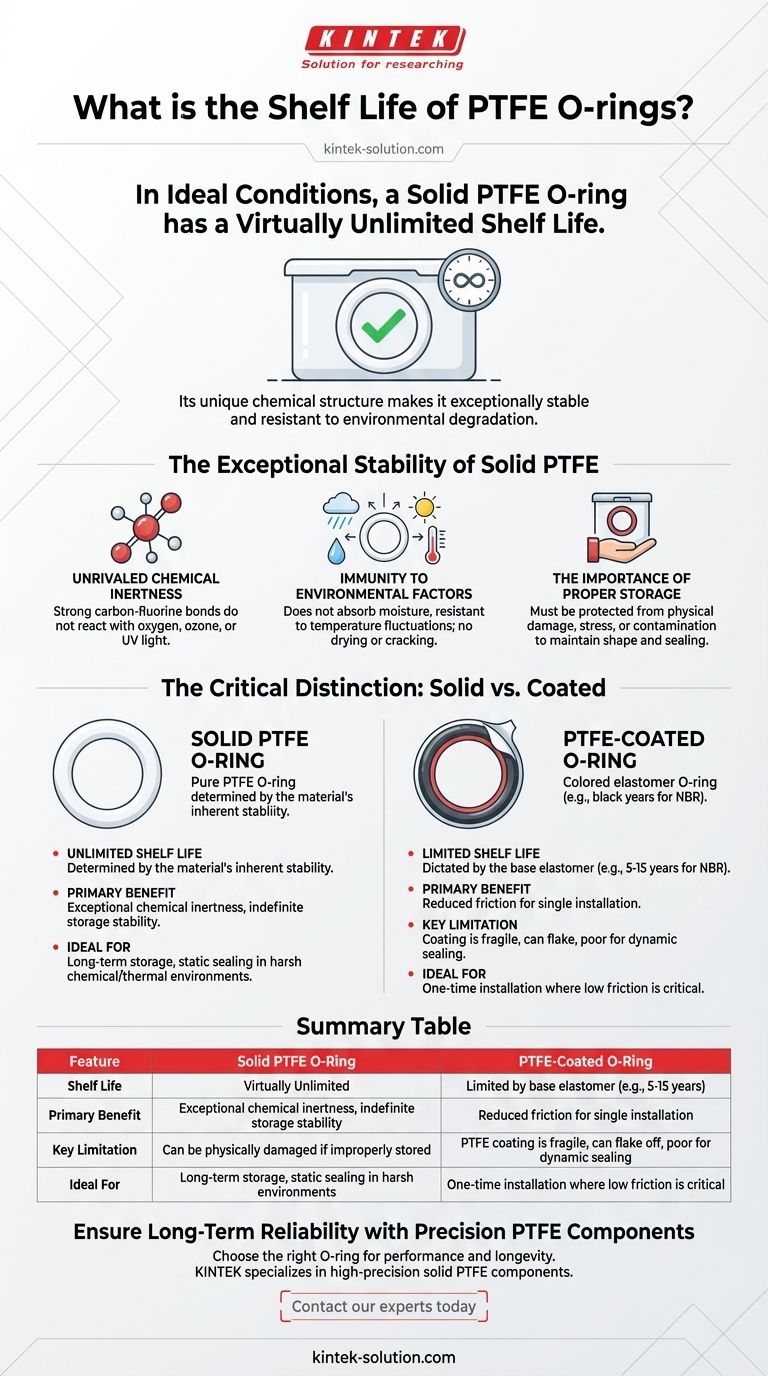

The Exceptional Stability of Solid PTFE

The "unlimited" shelf life of solid PTFE is not a marketing claim but a direct result of its material properties. Understanding why it is so stable is key to trusting its long-term reliability in storage.

Unrivaled Chemical Inertness

PTFE is one of the most chemically inert polymers known. Its carbon-fluorine bonds are incredibly strong, meaning it does not react with oxygen, ozone, or UV light—the primary culprits that cause aging and degradation in most other polymers.

Immunity to Environmental Factors

Unlike many elastomers that can dry out, crack, or change properties due to humidity or temperature fluctuations in storage, PTFE remains unaffected. It does not absorb moisture and maintains its properties across a vast temperature range.

The Importance of Proper Storage

While PTFE does not degrade chemically, it can still be physically damaged. Proper storage simply involves keeping the O-rings free from physical stress, compression, or contamination that could compromise their shape or sealing surface.

The Critical Distinction: Solid vs. Coated

Confusion often arises because the term "PTFE O-ring" can be used loosely. A PTFE-coated O-ring is a fundamentally different product with significant limitations.

Understanding PTFE-Coated O-Rings

These are standard elastomeric O-rings (made from materials like FKM, NBR, or EPDM) that have a very thin layer of PTFE applied to their surface. The goal of this coating is typically to reduce friction for a single installation.

Shelf Life is Dictated by the Base Elastomer

The shelf life of a coated O-ring is limited by its core material. An NBR O-ring with a PTFE coating still has the shelf life of NBR (typically 5-15 years, depending on storage). The coating offers no protection against the underlying material's natural aging process.

Performance Limitations of Coatings

It is critical to recognize that a PTFE coating is a surface treatment, not a structural component.

- Poor Wear Resistance: The coating is fragile and can easily rub off in dynamic applications, often functioning only as a one-time installation lubricant.

- Flaking and Contamination: Pieces of the worn coating can break off and contaminate the system, which is unacceptable in clean environments like food, medical, or semiconductor manufacturing.

- Porosity: The coating does not add chemical or thermal resistance. The base elastomer must be fully compatible with the application's demands, as the coating provides no meaningful protective barrier.

Making the Right Choice for Your Goal

Selecting the correct material from the start prevents long-term failure. Your decision should be based on the intended application and storage requirements.

- If your primary focus is indefinite storage and static sealing: Solid PTFE is the ideal choice, as its properties will not degrade over time.

- If your primary focus is reducing friction for a single installation: A PTFE-coated O-ring may be suitable, but acknowledge its shelf life is determined by the base material and it is not intended for dynamic sealing.

- If your primary focus is system cleanliness and long-term dynamic sealing: Avoid PTFE coatings due to the risk of flaking and poor wear resistance; instead, consider internally lubricated elastomers or other robust sealing solutions.

By understanding the difference between solid and coated materials, you can ensure your components provide the reliability and longevity your application demands.

Summary Table:

| Feature | Solid PTFE O-Ring | PTFE-Coated O-Ring |

|---|---|---|

| Shelf Life | Virtually unlimited | Limited by base elastomer (e.g., 5-15 years for NBR) |

| Primary Benefit | Exceptional chemical inertness, indefinite storage stability | Reduced friction for single installation |

| Key Limitation | Can be physically damaged if improperly stored | PTFE coating is fragile, can flake off, poor for dynamic sealing |

| Ideal For | Long-term storage, static sealing in harsh chemical/thermal environments | One-time installation where low friction is critical |

Ensure Long-Term Reliability with Precision PTFE Components

Choosing the right O-ring is critical for the performance and longevity of your equipment. At KINTEK, we specialize in manufacturing high-precision, solid PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

Why partner with KINTEK?

- Unmatched Material Expertise: We provide genuine solid PTFE parts with exceptional chemical resistance and stability, ensuring your components perform reliably, year after year.

- Precision Production: Our manufacturing processes prioritize accuracy and quality, delivering seals that meet the most demanding specifications.

- Custom Fabrication: Whether you need a prototype or a high-volume order, we can create the exact PTFE solution your application requires.

Don't let component degradation compromise your systems. Contact our experts today to discuss your specific needs and discover how our PTFE solutions can bring lasting reliability to your operations.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments