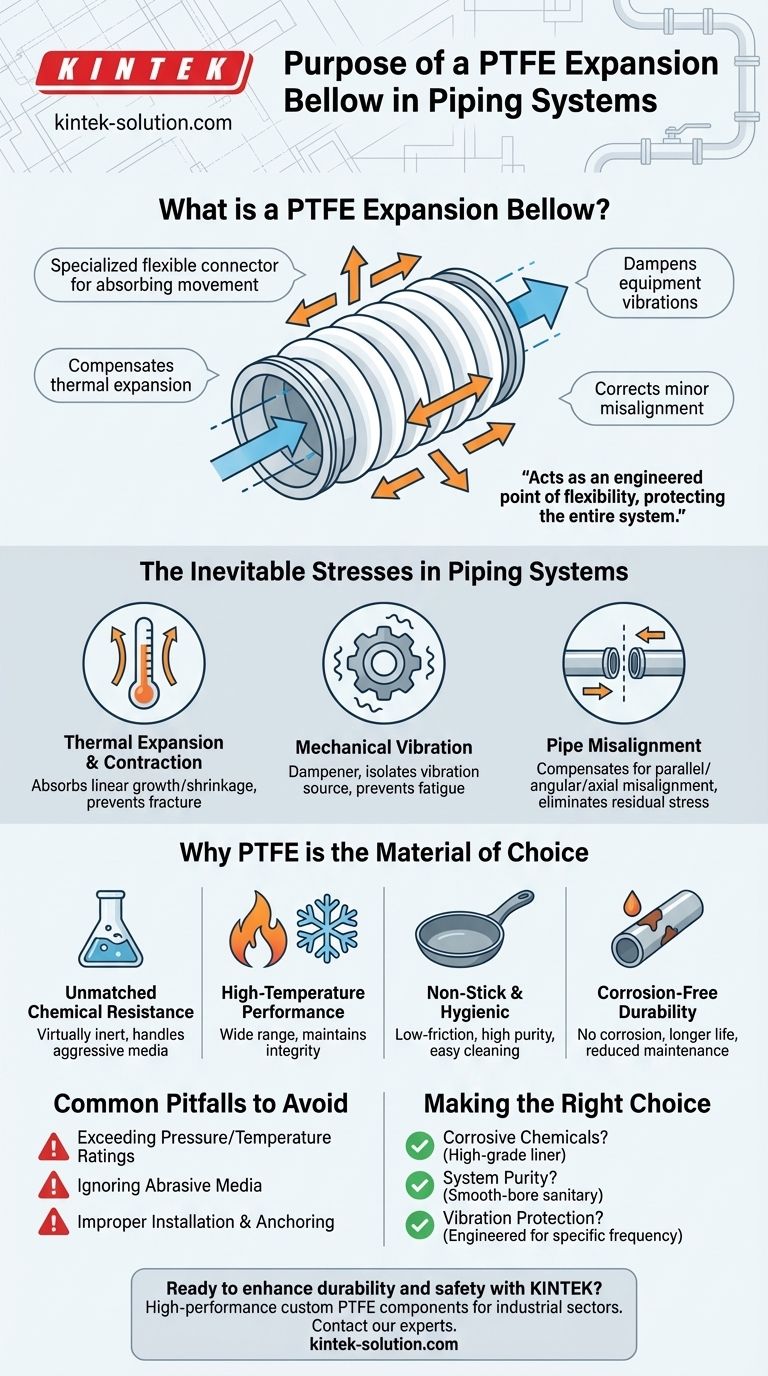

In short, a PTFE expansion bellow is a specialized flexible connector installed in a piping system to safely absorb movement. Its core purpose is to compensate for thermal expansion and contraction, dampen vibrations from equipment, and correct for minor pipe misalignment.

While a pipeline may seem rigid, it is a dynamic system constantly under stress from temperature, pressure, and mechanical forces. The PTFE expansion bellow acts as an engineered point of flexibility, protecting the entire system from cracking, leaking, and premature failure.

The Inevitable Stresses in Piping Systems

Piping systems are rarely static. Understanding the forces they endure reveals why a component designed for movement is not a luxury, but a necessity for system integrity and safety.

Thermal Expansion and Contraction

As process temperatures fluctuate, pipe materials expand and contract. Over long pipe runs, this movement can be significant, generating immense stress at fixed points like vessel nozzles, pump connections, and elbows.

An expansion bellow absorbs this linear growth and shrinkage, preventing the stress from building up to a point where it could fracture the pipe or damage connected equipment.

Mechanical Vibration

Pumps, compressors, and other rotating equipment introduce constant vibration into a piping system. Left unchecked, this energy travels through the pipe walls, fatiguing the metal and loosening connections over time.

A PTFE bellow acts as a dampener, isolating the source of the vibration and preventing its transmission throughout the rest of the system.

Pipe Misalignment

In the real world, achieving perfect pipe alignment during installation is difficult. A flexible bellow can compensate for minor parallel, angular, or axial misalignment between two pipe ends.

This eliminates the need to force pipes into place, which introduces dangerous residual stress into the system from day one.

Why PTFE is the Material of Choice

While expansion bellows can be made from metal or rubber, Polytetrafluoroethylene (PTFE) offers a unique combination of properties that make it ideal for the most demanding industrial applications.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals and corrosive fluids. This makes it the default choice for systems in chemical processing, pharmaceuticals, and manufacturing where aggressive media would quickly destroy metal or rubber alternatives.

High-Temperature Performance

PTFE can withstand a wide range of process temperatures, maintaining its structural integrity and flexibility in both hot and cold environments where other materials would become brittle or degrade.

Non-Stick and Hygienic Properties

The material has an exceptionally low-friction, non-stick surface. This prevents process media from building up on the internal walls, making it ideal for food, beverage, and pharmaceutical applications that demand high purity and easy cleaning.

Corrosion-Free Durability

Unlike metal bellows that are susceptible to chemical corrosion and fatigue cracking, PTFE does not corrode. This results in a longer service life and significantly reduced maintenance costs, especially in harsh environments.

Common Pitfalls to Avoid

While highly effective, the performance of a PTFE expansion bellow depends entirely on its correct application and installation. Overlooking key limitations can lead to system failure.

Exceeding Pressure and Temperature Ratings

Every bellow is engineered for a specific pressure and temperature range. Operating outside these limits can cause a catastrophic failure. Always verify that the component's specifications meet or exceed the system's maximum operating conditions.

Ignoring Abrasive Media

PTFE is a durable material but can be susceptible to wear from highly abrasive slurries or solids in the fluid stream. In these cases, an alternative material or a lined bellow may be necessary.

Improper Installation and Anchoring

An expansion bellow is not a structural support. The piping system must be properly anchored and guided on either side of the bellow to ensure it only absorbs the specific movements it was designed for. Incorrect anchoring can cause the bellow to buckle or rupture under pressure.

Making the Right Choice for Your Goal

Selecting the right expansion bellow is critical for maximizing system reliability and safety. Your primary operational goal should guide your decision.

- If your primary focus is handling highly corrosive chemicals: Prioritize a bellow with a high-grade, thick-walled PTFE liner to ensure maximum chemical compatibility and service life.

- If your primary focus is system purity and cleanliness: Select a bellow with a smooth-bore PTFE construction specifically designed for sanitary applications in the food, beverage, or pharmaceutical industries.

- If your primary focus is protecting sensitive equipment from vibration: Ensure the bellow is engineered to absorb the specific frequency and amplitude of the vibrations generated by your pumps or machinery.

By strategically placing this component, you transform a rigid, vulnerable pipeline into a resilient and durable system.

Summary Table:

| Function | Benefit |

|---|---|

| Compensates for Thermal Expansion/Contraction | Prevents pipe stress and cracking |

| Dampens Mechanical Vibration | Protects equipment and reduces fatigue |

| Corrects Minor Pipe Misalignment | Simplifies installation and eliminates residual stress |

Ready to enhance the durability and safety of your piping system?

KINTEK specializes in manufacturing high-performance PTFE components, including custom expansion bellows, for the semiconductor, medical, laboratory, and industrial sectors. Our bellows are engineered to provide unmatched chemical resistance, high-temperature performance, and long-lasting reliability.

We offer precision production and custom fabrication from prototypes to high-volume orders to meet your exact specifications. Protect your investment and ensure system integrity—contact our experts today to discuss your application needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection