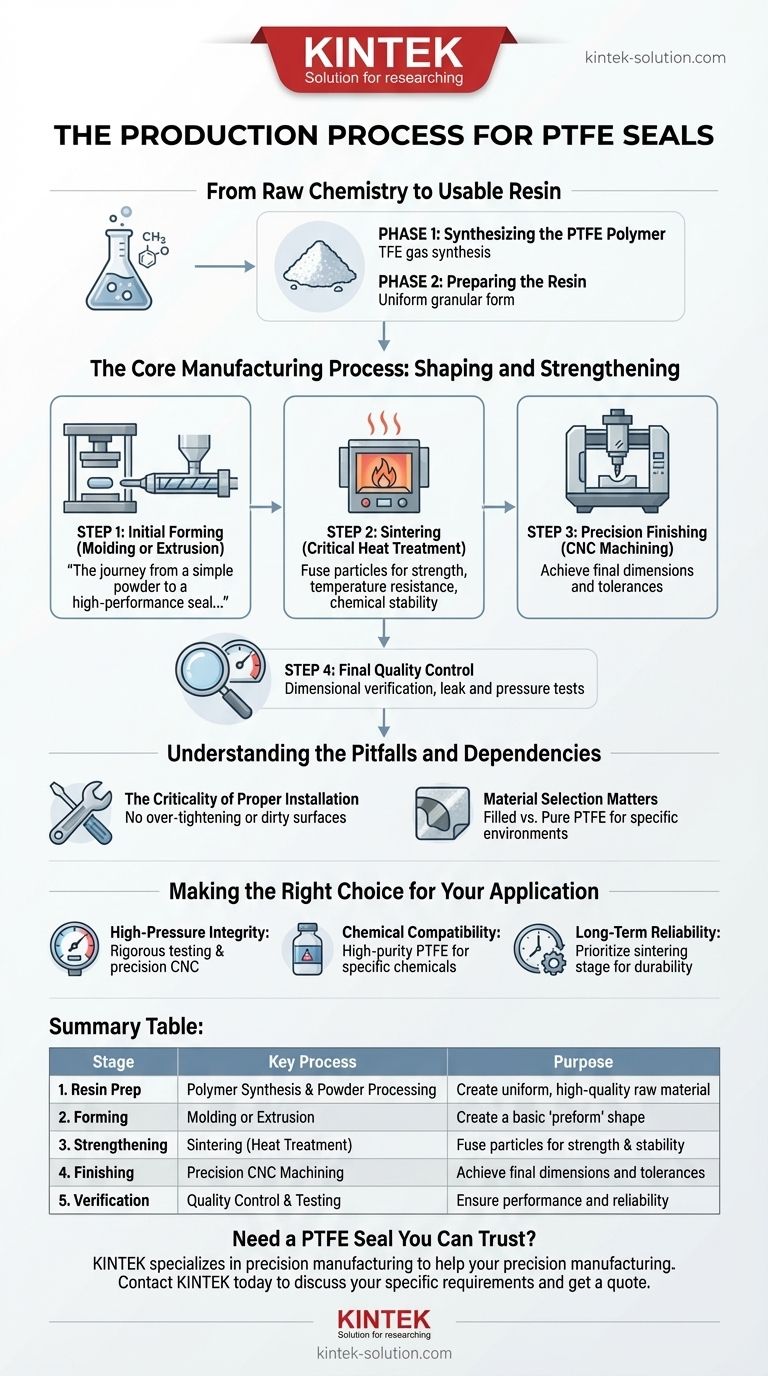

The production of a PTFE seal is a multi-stage process that transforms raw polymer resin into a precision-engineered component. It begins with selecting high-quality PTFE resins, which are then formed into a basic shape through molding or extrusion. The seal then undergoes a critical heat treatment process called sintering to lock in its mechanical properties, followed by precise CNC machining to achieve its final dimensions and a final quality control inspection.

The journey from a simple powder to a high-performance seal is one of refinement. The manufacturing process is not just about creating a shape; it's about systematically enhancing the inherent properties of PTFE—its chemical resistance, temperature stability, and low friction—at every step to create a reliable component for demanding applications.

From Raw Chemistry to Usable Resin

Before a seal can be made, the Polytetrafluoroethylene (PTFE) polymer itself must be created and prepared. This foundational stage determines the ultimate quality of the final product.

Phase 1: Synthesizing the PTFE Polymer

The process begins at a chemical level, starting with ingredients like fluorspar, hydrofluoric acid, and chloroform. These are heated in a reaction chamber to synthesize tetrafluoroethylene (TFE) gas. This gas is then polymerized—a process where individual TFE molecules link together into long chains—to form the solid grains of PTFE resin.

Phase 2: Preparing the Resin for Production

For seal manufacturing, only high-quality, pure PTFE resins are selected. These solid grains are processed into a consistent granular or powdered form, which serves as the raw material for the next stage. This ensures uniformity and predictable behavior during manufacturing.

The Core Manufacturing Process: Shaping and Strengthening

With the prepared resin, the physical process of creating the seal begins. Each step is designed to build upon the last, culminating in a finished part that meets exact specifications.

Step 1: Initial Forming (Molding or Extrusion)

The PTFE powder is compressed into a "preform," a rough shape of the final component. This is typically done through molding (pressing the powder into a die) or extrusion (forcing the material through a die) to create a basic form, often a tube or rod, from which the seals will be machined.

Step 2: Sintering (Critical Heat Treatment)

The preform is heated to a temperature just below its melting point in a carefully controlled oven. This process, known as sintering, causes the individual PTFE particles to fuse together. This is the most critical step for developing the material's final mechanical strength, temperature resistance, and chemical stability.

Step 3: Precision Finishing (CNC Machining)

After sintering, the hardened PTFE stock is machined to its final, precise dimensions. Computer Numerical Control (CNC) machines cut the material to tight tolerances, ensuring the seal will fit and function perfectly in its intended application. This step defines the seal's final geometry, including its critical sealing surfaces.

Step 4: Final Quality Control

Every finished seal undergoes rigorous testing to ensure it meets performance standards. This typically includes dimensional verification, as well as functional checks like leak and pressure tests, to guarantee reliability in the field.

Understanding the Pitfalls and Dependencies

A perfectly manufactured seal can still fail if its dependencies and limitations are not understood. The performance of a PTFE seal is as much about its application and installation as it is about its production.

The Criticality of Proper Installation

The final performance of the seal is determined at the moment of installation. Over-tightening can deform the soft PTFE material, creating a leak path. Likewise, installing a seal onto a dirty or damaged surface will compromise its ability to function, regardless of how well it was made.

Material Selection Matters

The term "PTFE" can describe the base polymer, but manufacturers often add fillers (like glass, carbon, or bronze) to the resin to enhance specific properties like wear resistance or compressive strength. Choosing a seal made from a material grade unsuited for the application's chemical environment or temperature range is a common source of failure.

Making the Right Choice for Your Application

Understanding the production process empowers you to select the right seal for your specific goal.

- If your primary focus is high-pressure integrity: Choose a seal with documented evidence of rigorous pressure testing and precision CNC machining, as this ensures it can hold its shape and function under load.

- If your primary focus is chemical compatibility: Ensure the seal is manufactured from a high-purity grade of PTFE resin appropriate for the specific chemicals it will encounter, especially in industries like oil and gas.

- If your primary focus is long-term reliability: Prioritize seals from a manufacturing process that emphasizes the sintering stage, as this step is crucial for establishing the material's durability and resistance to degradation.

Ultimately, knowing how a PTFE seal is made provides the insight needed to select a component you can trust in your most critical systems.

Summary Table:

| Stage | Key Process | Purpose |

|---|---|---|

| 1. Resin Prep | Polymer Synthesis & Powder Processing | Create uniform, high-quality raw material |

| 2. Forming | Molding or Extrusion | Create a basic 'preform' shape |

| 3. Strengthening | Sintering (Heat Treatment) | Fuse particles for strength & stability |

| 4. Finishing | Precision CNC Machining | Achieve final dimensions and tolerances |

| 5. Verification | Quality Control & Testing | Ensure performance and reliability |

Need a PTFE Seal You Can Trust?

Understanding the production process is the first step; receiving a component engineered for your exact application is the next. KINTEK specializes in the precision manufacturing of high-performance PTFE components, including seals, liners, and labware.

We serve demanding industries like semiconductor, medical, laboratory, and industrial processing, where material purity, dimensional accuracy, and reliability are non-negotiable. Our process prioritizes critical steps like controlled sintering and precision CNC machining to ensure your seals deliver maximum chemical resistance, temperature stability, and long-term performance.

We offer custom fabrication from prototypes to high-volume orders.

Contact KINTEL today to discuss your specific requirements and get a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the primary applications of PTFE fasteners and custom parts? Critical Solutions for Extreme Environments

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions