In short, CNC machining Teflon is a subtractive manufacturing process where computer-controlled tools precisely cut away material to create a final part. While Teflon's softness makes it easy to cut, its unique properties—like poor heat conductivity, high thermal expansion, and a tendency to deform under pressure—make achieving precision a significant technical challenge. This process is common in the aerospace, medical, and automotive industries where Teflon's chemical inertness and low friction are critical.

The core challenge of machining Teflon is not in the cutting, but in the control. Its inherent softness and thermal instability mean that standard machining practices for metals or even other plastics will fail. Success requires specialized tooling, careful heat management, and a deep understanding of how the material deforms.

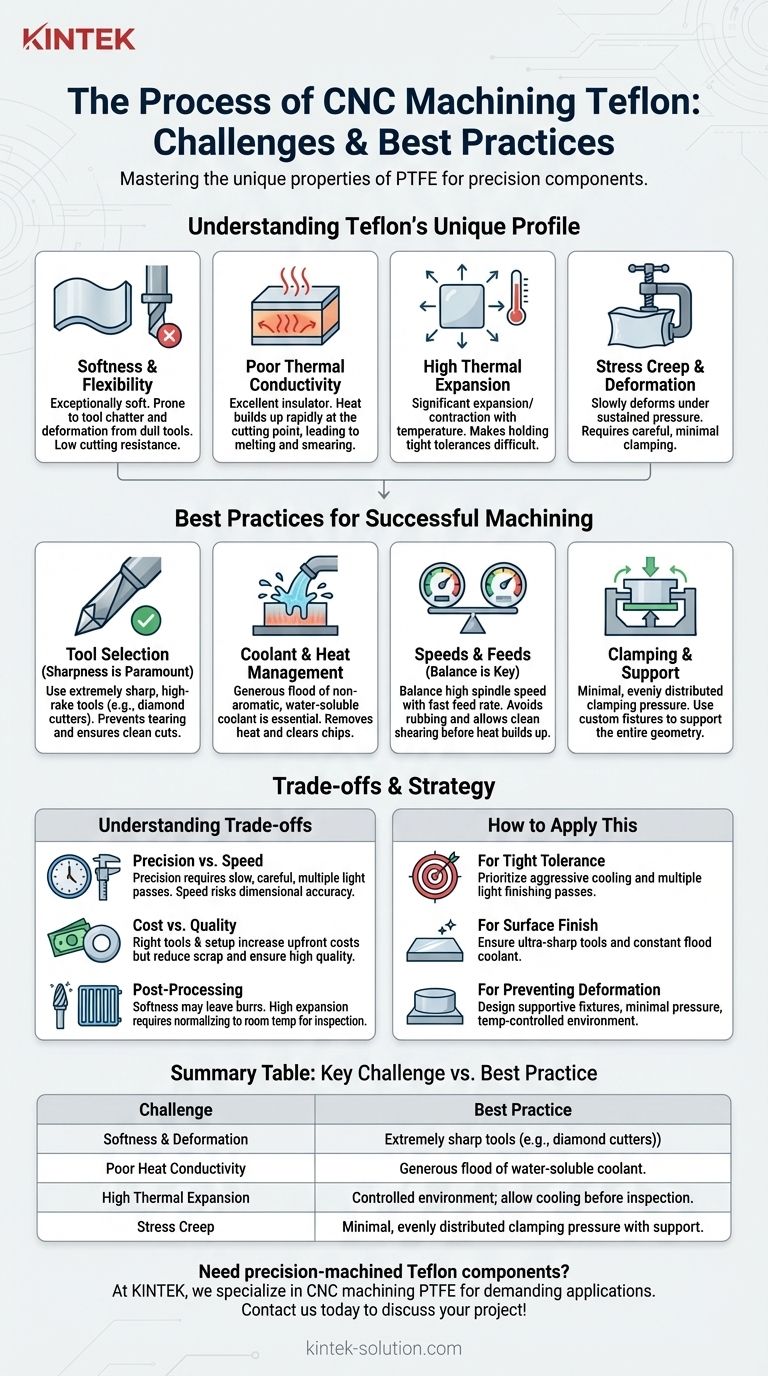

Understanding Teflon's Unique Machining Profile

To machine Teflon effectively, you must first understand its distinct material properties. These characteristics dictate every choice, from the tools you use to the speed of the machine.

Softness and Flexibility

Teflon (PTFE) is an exceptionally soft material with low strength compared to other polymers like Nylon. This softness means it offers little resistance to the cutting tool.

However, this flexibility also makes it prone to tool chatter and deformation. The material can easily be pushed away by a dull tool rather than being cleanly sheared, resulting in a poor surface finish and dimensional inaccuracy.

Poor Thermal Conductivity

Unlike metals, Teflon is an excellent thermal insulator. It does not dissipate heat well, causing heat to build up rapidly at the point of contact between the tool and the workpiece.

This localized heat is a primary cause of machining failures, as it can lead to material melting, smearing, and significant changes in the part's dimensions.

High Coefficient of Thermal Expansion

Teflon expands and contracts significantly with changes in temperature. This property, combined with its poor thermal conductivity, creates a major challenge for holding tight tolerances.

As the cutting process generates heat, the part will expand. If measurements are taken while the part is still warm, it will be out of tolerance once it cools and shrinks to its final size.

Stress Creep and Deformation

Teflon has a high rate of stress creep, meaning it has a tendency to slowly deform or "flow" when subjected to sustained pressure.

This is especially critical during clamping or fixturing. Excessive clamping pressure can permanently deform the material before a single cut is made, making it impossible to achieve the intended final geometry.

Best Practices for Successful Machining

Adapting your process to Teflon's unique profile is non-negotiable. Success depends on a specific combination of tooling, coolant, and machine parameters.

Tool Selection: Sharpness is Paramount

The single most important factor is tool sharpness. Use extremely sharp tools with a high rake angle and narrow profile.

Dull or improperly shaped tools will plow through the material instead of cutting it, causing it to tear, smear, and deform under pressure. Specialized diamond cutters often provide the best performance and tool life.

Coolant and Heat Management

Aggressive heat management is essential. The goal is to remove heat as quickly as it is generated to prevent thermal expansion and melting.

A generous flood of non-aromatic, water-soluble coolant is the recommended approach. This not only cools the workpiece but also helps to clear away chips, ensuring a clean cut and superior surface finish.

Cutting Speeds and Feeds

You must carefully balance cutting speeds and feed rates. High cutting speeds can generate excessive heat, while a feed rate that is too slow can cause the tool to rub against the material, also generating heat.

Generally, a higher spindle speed combined with a faster feed rate produces the best results, as it allows the tool to shear the material cleanly and exit the cut before significant heat can build up.

Workpiece Clamping and Support

Use minimal, evenly distributed clamping pressure to hold the workpiece. Over-tightening the fixture is a common mistake that induces stress and leads to deformation.

For delicate or thin-walled parts, consider using custom fixtures that support the entire part geometry to prevent it from flexing or distorting during the machining operation.

Understanding the Trade-offs

Machining Teflon involves balancing competing priorities. Understanding these trade-offs is key to planning a successful manufacturing run.

Precision vs. Speed

Achieving tight tolerances in Teflon is a slow process that requires careful heat management, sharp tools, and potentially multiple light passes. Rushing the process by increasing cutting depths or speeds will almost certainly sacrifice dimensional accuracy due to heat buildup and tool pressure.

Cost vs. Quality

Using the right tools, like diamond-coated cutters, and investing time in proper setup and coolant management increases upfront costs. However, attempting to cut corners with standard tooling or rushing the setup often leads to a high scrap rate, ultimately costing more in wasted material and time.

The Need for Post-Processing

Even with a perfect machining process, some features may require post-processing. The softness of the material can result in small burrs, and the high thermal expansion means parts may need to rest and normalize to room temperature before a final quality inspection can be accurately performed.

How to Apply This to Your Project

Your machining strategy should be dictated by the most critical requirement of the final part.

- If your primary focus is tight tolerance: Prioritize aggressive cooling and take multiple light finishing passes to minimize heat and tool pressure.

- If your primary focus is surface finish: Ensure you are using extremely sharp, dedicated tooling and a constant flood of high-quality coolant.

- If your primary focus is preventing deformation: Design fixtures that provide broad support with minimal clamping pressure and machine the part in a temperature-controlled environment.

Ultimately, mastering the machining of Teflon means treating it not as a difficult material, but as a unique one that demands its own specialized approach.

Summary Table:

| Key Challenge | Best Practice | Why It Matters |

|---|---|---|

| Softness & Deformation | Use extremely sharp tools (e.g., diamond cutters) | Prevents tearing, smearing, and ensures a clean cut |

| Poor Heat Conductivity | Apply a generous flood of water-soluble coolant | Manages heat buildup to avoid melting and dimensional inaccuracy |

| High Thermal Expansion | Machine in a controlled environment; allow parts to cool before final inspection | Ensures parts meet tight tolerances after cooling to room temperature |

| Stress Creep | Use minimal, evenly distributed clamping pressure with supportive fixtures | Prevents permanent deformation of the workpiece during machining |

Need precision-machined Teflon components?

At KINTEK, we specialize in CNC machining PTFE (Teflon) for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in managing Teflon's unique properties—like its softness and thermal instability—ensures your parts are manufactured to the highest standards of accuracy and quality.

We offer custom fabrication from prototypes to high-volume orders, utilizing specialized tooling and precise process controls to overcome the challenges of machining Teflon.

Contact us today to discuss your project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers