To be direct, there is no single "primary" filler for Polytetrafluoroethylene (PTFE) because the filler is chosen specifically to enhance the properties required for a given application. For electrical and thermal management, ceramics are the predominant choice, while for mechanical strength and wear resistance, glass and carbon are the most common.

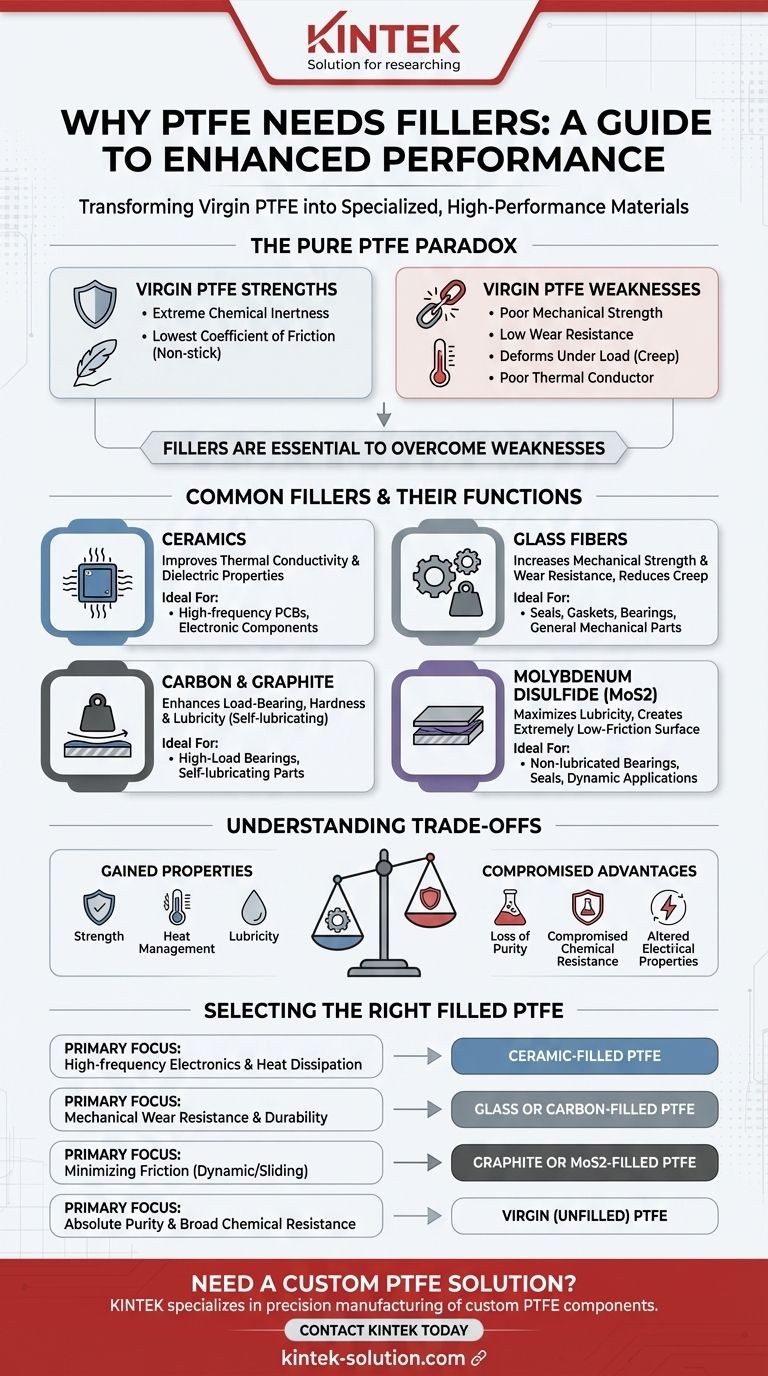

The core principle is that pure, or "virgin," PTFE has remarkable chemical resistance and low friction but possesses significant mechanical and thermal weaknesses. Fillers are not optional additives; they are essential components that transform PTFE into a specialized, high-performance material engineered for a specific task.

Why Pure PTFE Needs Reinforcement

Pure PTFE is a unique material, but its inherent properties create limitations for many engineering applications. Understanding these weaknesses is key to understanding the role of fillers.

The Strengths of Virgin PTFE

Virgin PTFE is known for its extreme chemical inertness, making it resistant to nearly all industrial chemicals and solvents. It also has one of the lowest coefficients of friction of any solid material, giving it its famous non-stick quality.

The Weaknesses of Virgin PTFE

However, pure PTFE suffers from poor mechanical strength, low wear resistance, and a tendency to deform under load (a phenomenon known as "creep"). It is also a poor thermal conductor, meaning it cannot dissipate heat effectively.

A Guide to Common PTFE Fillers and Their Functions

Fillers are incorporated into the PTFE matrix to overcome its natural weaknesses. Each type of filler imparts distinct properties.

Ceramics for Electrical & Thermal Management

For applications like high-frequency printed circuit boards (PCBs), ceramic powders are the go-to filler. They are used to precisely modify the material's dielectric properties and significantly increase its thermal conductivity, allowing electronic components to run cooler and more efficiently.

Glass for General-Purpose Mechanical Strength

Glass fibers are one of the most common fillers for improving the mechanical properties of PTFE. Adding glass dramatically increases compressive strength and rigidity, making the material far more resistant to wear and creep.

Carbon & Graphite for Strength and Lubricity

Carbon is added to increase compressive strength, hardness, and load-bearing capabilities beyond what glass can offer. Graphite is often used in combination with carbon or glass to lower the coefficient of friction and improve lubricity, creating a self-lubricating composite.

Molybdenum Disulfide (MoS2) for Enhanced Lubricity

Often called "Moly," MoS2 is added for one primary reason: to create an extremely low-friction surface. It acts as a dry lubricant, making it ideal for dynamic applications like seals and non-lubricated bearings.

Understanding the Trade-offs

Adding fillers is an engineering compromise. While you gain desired properties, you also sacrifice some of PTFE's original advantages.

The Loss of Purity

The moment a filler is introduced, the material is no longer virgin PTFE. This makes filled PTFE unsuitable for applications with the highest purity requirements, such as in certain medical, pharmaceutical, or semiconductor manufacturing processes.

Compromised Chemical Resistance

While PTFE itself is nearly inert, fillers are not. Glass-filled PTFE, for example, can be attacked by strong alkalis or hydrofluoric acid, which virgin PTFE would easily resist.

Altered Electrical Properties

Pure PTFE is an excellent electrical insulator. However, adding conductive fillers like carbon or graphite fundamentally changes this property, making the composite more electrically conductive. This can be a desired feature for static-dissipating applications or an unintended flaw if insulation is the goal.

Selecting the Right Filled PTFE for Your Application

The choice of filler must be driven entirely by the primary demands of your project.

- If your primary focus is high-frequency electronics: You need a material with controlled dielectric properties and good thermal dissipation, making ceramic-filled PTFE the definitive choice.

- If your primary focus is mechanical wear resistance: For components like seals, bearings, or gaskets, you need strength and durability, making glass or carbon-filled PTFE the standard solution.

- If your primary focus is minimizing friction: For dynamic, sliding applications, you need enhanced lubricity, making graphite or MoS2-filled PTFE the most effective option.

- If your primary focus is absolute purity or broad chemical resistance: You must avoid fillers entirely, meaning virgin (unfilled) PTFE is the only suitable choice.

Ultimately, understanding the function of each filler transforms material selection from a simple choice into a precise engineering decision.

Summary Table:

| Common Filler | Primary Function | Ideal For |

|---|---|---|

| Ceramics | Improves thermal conductivity & dielectric properties | High-frequency PCBs, electronics |

| Glass Fibers | Increases mechanical strength & wear resistance | Seals, gaskets, bearings |

| Carbon/Graphite | Enhances load-bearing & lubricity | Self-lubricating parts |

| Molybdenum Disulfide (MoS2) | Maximizes lubricity, low friction | Non-lubricated bearings, seals |

| Virgin (Unfilled) PTFE | Maximum chemical resistance & purity | Medical, pharmaceutical, semiconductor |

Need a Custom PTFE Solution for Your Specific Application?

Choosing the right filled PTFE is a critical engineering decision that directly impacts the performance, longevity, and cost-effectiveness of your components. At KINTEK, we specialize in the precision manufacturing of custom PTFE components—from seals and liners to complex labware—for the semiconductor, medical, laboratory, and industrial sectors.

We don't just supply materials; we provide engineered solutions. Our experts will work with you to select the optimal filler combination to meet your exact requirements for strength, thermal management, lubricity, or chemical resistance.

Let us help you transform your design into a high-performance reality.

Contact KINTEK today to discuss your project, request a quote, or explore our prototyping and high-volume production capabilities.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments