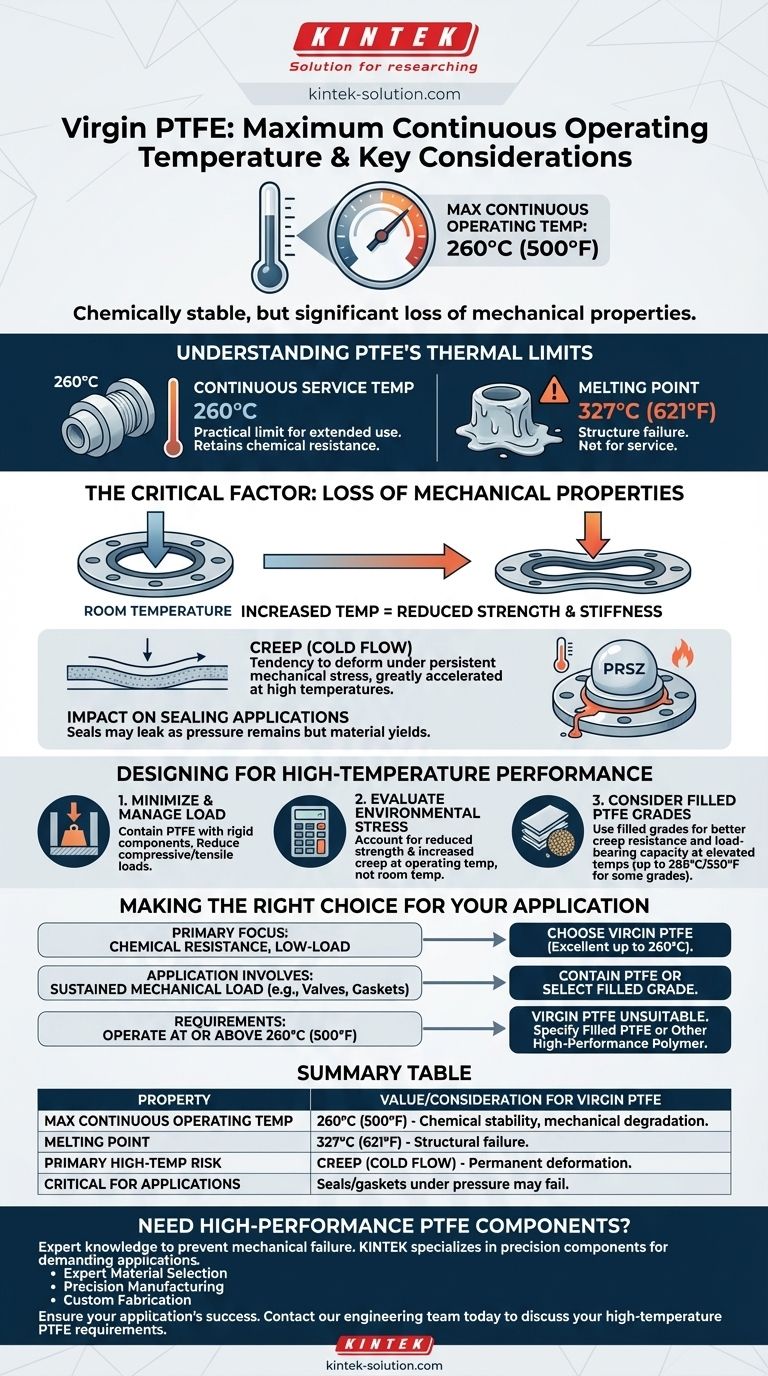

The maximum continuous operating temperature for virgin PTFE is 260°C (500°F). While the material remains chemically stable at this temperature, it experiences a significant loss of its mechanical properties. For any practical application, especially those under load, this degradation in strength and stiffness is a more critical design constraint than the temperature ceiling itself.

Your primary concern when using virgin PTFE near its thermal limit is not chemical decomposition, but mechanical failure. The material becomes significantly softer and more prone to deforming under pressure, a factor that must be central to your design strategy.

Understanding PTFE's Thermal Limits

To use PTFE effectively at high temperatures, you must distinguish between its different thermal properties and understand which ones matter most for your application.

The Continuous Service Temperature

The established continuous service temperature for virgin PTFE is 260°C (500°F). This is the maximum temperature at which the material can operate for extended periods without significant chemical degradation.

Its fundamental properties, such as extreme chemical resistance and insolubility in most solvents, are maintained up to this point.

Service Temperature vs. Melting Point

It is critical not to confuse the service temperature with the melting point. Virgin PTFE has a much higher melting point of approximately 327°C (621°F).

The melting point is the temperature of a phase transition where the material loses all structural integrity. The service temperature is the practical limit where it can still function as a useful engineering component.

The Critical Factor: Loss of Mechanical Properties

As virgin PTFE approaches its 260°C limit, its behavior under physical stress changes dramatically. This is the most common source of failure in high-temperature applications.

Reduced Strength and Stiffness

While virgin PTFE has a moderate tensile strength of 20-40 MPa at room temperature, this value decreases substantially as it heats up. The material becomes much softer and more flexible, reducing its ability to withstand force.

The Challenge of Creep (Cold Flow)

The most significant issue is creep, also known as cold flow. This is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

While virgin PTFE is subject to creep even at room temperature, this effect is greatly accelerated at higher temperatures. A component under constant load, such as a gasket or seal, will deform much more rapidly near its service temperature limit.

Impact on Sealing Applications

This behavior is especially critical in sealing. A PTFE gasket that provides a reliable seal under pressure at 150°C may begin to creep and allow leakage when the system reaches 250°C, even if the pressure remains the same.

Designing for High-Temperature Performance

Successfully using virgin PTFE near its thermal limit requires a design approach that actively mitigates its mechanical weaknesses.

Minimize and Manage Load

Your design should aim to minimize sustained compressive or tensile loads on the PTFE component. Where possible, use metal or other rigid housing components to contain the PTFE and prevent it from deforming under pressure.

Evaluate Environmental Stress

While chemically inert, the combination of high temperature and mechanical load is the primary failure vector. Ensure your design calculations account for the reduced strength and increased creep rate at your target operating temperature, not at room temperature.

Consider Filled PTFE Grades

For applications requiring better mechanical performance at high temperatures, filled grades of PTFE are often necessary. Additives such as glass fiber, carbon, or bronze dramatically improve creep resistance and load-bearing capability.

Some enhanced grades can increase the continuous service temperature limit to 288°C (550°F), but their primary benefit is maintaining mechanical properties at elevated temperatures.

Making the Right Choice for Your Application

Your material choice and design strategy must be aligned with the specific demands of your project.

- If your primary focus is chemical resistance in a low-load environment: Virgin PTFE is an excellent choice up to 260°C, as its chemical inertness remains its strongest asset.

- If your application involves sustained mechanical load (e.g., a pressurized valve seat or gasket): You must design to contain the PTFE or, more likely, select a filled grade of PTFE to prevent failure from creep.

- If you need to operate reliably at or above 260°C (500°F): Virgin PTFE is unsuitable. You must specify a filled PTFE grade or a different class of high-performance polymer.

Ultimately, successful design with PTFE at high temperatures comes from understanding that its mechanical performance, not its thermal stability, is the true limiting factor.

Summary Table:

| Property | Value for Virgin PTFE | Key Consideration |

|---|---|---|

| Max Continuous Operating Temp | 260°C (500°F) | Chemical stability is maintained, but mechanical properties degrade significantly. |

| Melting Point | 327°C (621°F) | Not the practical limit for use; structural failure occurs here. |

| Primary High-Temp Risk | N/A | Creep (Cold Flow): Permanent deformation under sustained load. |

| Critical for Applications | N/A | Seals and gaskets under pressure may fail due to loss of mechanical strength. |

Need High-Performance PTFE Components That Withstand Extreme Temperatures?

Designing with PTFE at its thermal limits requires expert knowledge to prevent mechanical failure from creep and deformation. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the most demanding applications in the semiconductor, medical, and industrial sectors.

We offer:

- Expert Material Selection: Guidance on choosing between virgin PTFE for ultimate chemical resistance or filled grades for superior mechanical performance at high temperatures.

- Precision Manufacturing: Components that meet exact specifications, ensuring reliability under thermal and mechanical stress.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions to your specific operational needs.

Ensure your application's success. Contact our engineering team today to discuss your high-temperature PTFE requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs