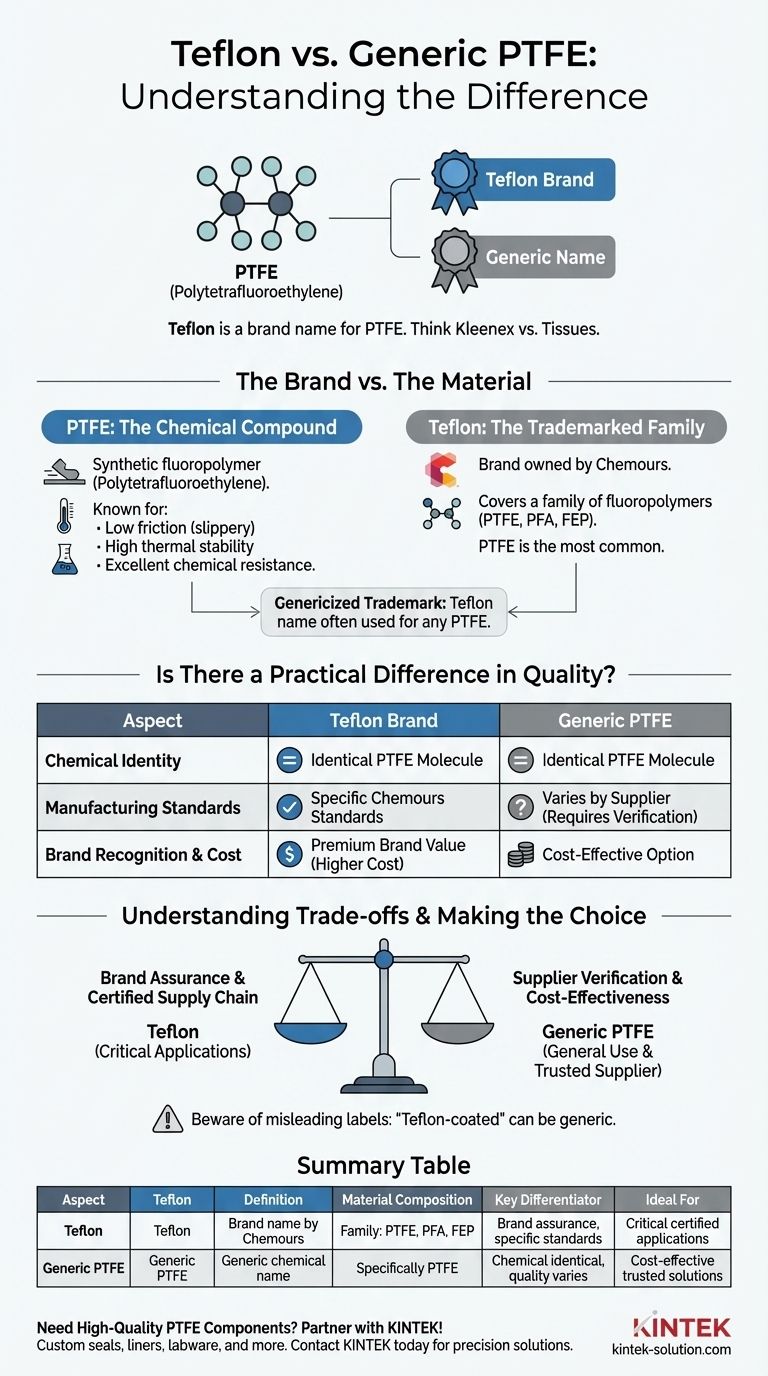

At its core, Teflon is a brand name for PTFE. Polytetrafluoroethylene (PTFE) is the generic chemical name for the material, while Teflon is the registered trademark under which the Chemours company (originally DuPont) markets its family of fluoropolymer products, which includes PTFE. For most practical purposes, the two terms refer to the same high-performance, non-stick polymer.

The relationship between PTFE and Teflon is the same as that between tissues and the Kleenex brand. While every roll of Teflon-branded tape is made from a fluoropolymer like PTFE, not all PTFE-based products are branded Teflon. The underlying material is often identical; the difference is the name and the manufacturer.

The Brand vs. The Material

Understanding the distinction requires separating the chemical compound from the commercial product. One is a specific molecule, while the other is a trademarked family of materials.

PTFE: The Chemical Compound

Polytetrafluoroethylene, or PTFE, is a synthetic fluoropolymer. It is a specific chemical compound known for a remarkable set of properties.

These properties include an extremely low coefficient of friction (making it very slippery), high thermal stability, and excellent resistance to chemical corrosion. It is the foundational material responsible for the "non-stick" quality we associate with it.

Teflon: The Trademarked Family

Teflon is not a single material but a brand name owned by Chemours. This brand is applied to a family of related fluoropolymers.

While PTFE is the most famous material in this family, the Teflon brand also covers other polymers like PFA (perfluoroalkoxy alkane) and FEP (fluorinated ethylene propylene). These related materials offer slightly different properties that may be better for certain industrial applications, but PTFE remains the most common.

The Power of a Name

The relationship is a classic example of a genericized trademark. Just as we often ask for a "Kleenex" instead of a "facial tissue," the name Teflon has become a common way to refer to PTFE itself. This brand recognition is powerful but does not change the chemistry of the underlying material.

Is There a Practical Difference in Quality?

This is the central issue for most users: does paying for the Teflon brand guarantee a better product than a generic PTFE equivalent? The answer depends on your focus.

Chemical and Performance Identity

From a chemical standpoint, there is no difference between a product made with Teflon-branded PTFE and one made with generic PTFE. The polymer's properties—its non-stick nature, temperature resistance, and chemical inertness—are inherent to the polytetrafluoroethylene molecule itself, regardless of who manufactures it.

The Role of Manufacturing Standards

The primary differentiator is not the material but the quality control and manufacturing process of the final product. Chemours holds its Teflon-branded products to specific internal standards.

However, many other reputable manufacturers produce high-quality generic PTFE that meets or exceeds industry specifications. The quality of a finished good, like a gasket or a non-stick pan, depends more on the integrity of the manufacturer than on the brand name of the raw material.

Brand Recognition and Cost

Often, the most noticeable difference is the price. The Teflon brand name carries significant value due to decades of marketing and a reputation for reliability. This can result in a higher cost for a product that offers no tangible performance benefit over a high-quality generic alternative.

Understanding the Trade-offs

Choosing between a branded and a generic product involves weighing brand assurance against cost and supplier verification.

The Cost of Assurance

When you purchase a Teflon-branded product, you are partly paying for the assurance that it meets Chemours' specific quality and purity standards. For highly sensitive applications in aerospace or medicine, this certified supply chain can be a critical requirement.

The Burden of Verification

With generic PTFE, the responsibility falls on you to select a reputable supplier. The term "PTFE" only describes the chemical; it does not guarantee the absence of impurities or the quality of the manufacturing process. A trusted manufacturer of generic PTFE, however, will provide a product that is functionally identical to its branded counterpart.

Misleading Labels

Be aware that the Teflon brand is sometimes used loosely in marketing. A product might be described as "Teflon-coated" as a generic term for any PTFE coating. Always look for official branding if you specifically require a Chemours-certified product.

Making the Right Choice for Your Goal

Your decision should be based on your specific application and tolerance for risk, not just on the name.

- If your primary focus is cost-effectiveness for general use: A generic PTFE product from a trusted, well-reviewed supplier is functionally identical and the most economical choice.

- If your primary focus is a certified supply chain for a critical application: Specifying the Teflon brand ensures you are getting a product that adheres to a single, consistent set of manufacturing standards.

- If you are choosing consumer goods (like cookware): Evaluate the overall product quality and the manufacturer's reputation, as the application process of the non-stick coating matters more than the brand of the PTFE itself.

Ultimately, an informed decision relies on understanding that while the underlying material is the same, the brand name serves as a proxy for a specific manufacturer's quality control.

Summary Table:

| Aspect | Teflon | Generic PTFE |

|---|---|---|

| Definition | Brand name owned by Chemours | Generic name for the chemical polymer |

| Material Composition | A family of fluoropolymers (PTFE, PFA, FEP) | Specifically PTFE (Polytetrafluoroethylene) |

| Key Differentiator | Brand assurance & specific manufacturer standards | Chemical properties are identical; quality depends on the supplier |

| Ideal For | Critical applications requiring a certified supply chain | Cost-effective solutions from a trusted manufacturer |

Need High-Quality PTFE Components? Partner with KINTEK!

Whether your project requires the certified assurance of a specific brand or the cost-effectiveness of high-quality generic PTFE, KINTEK delivers precision. We manufacture custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring the right solution for your application's demands and budget.

Contact KINTEK today to discuss your PTFE needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments