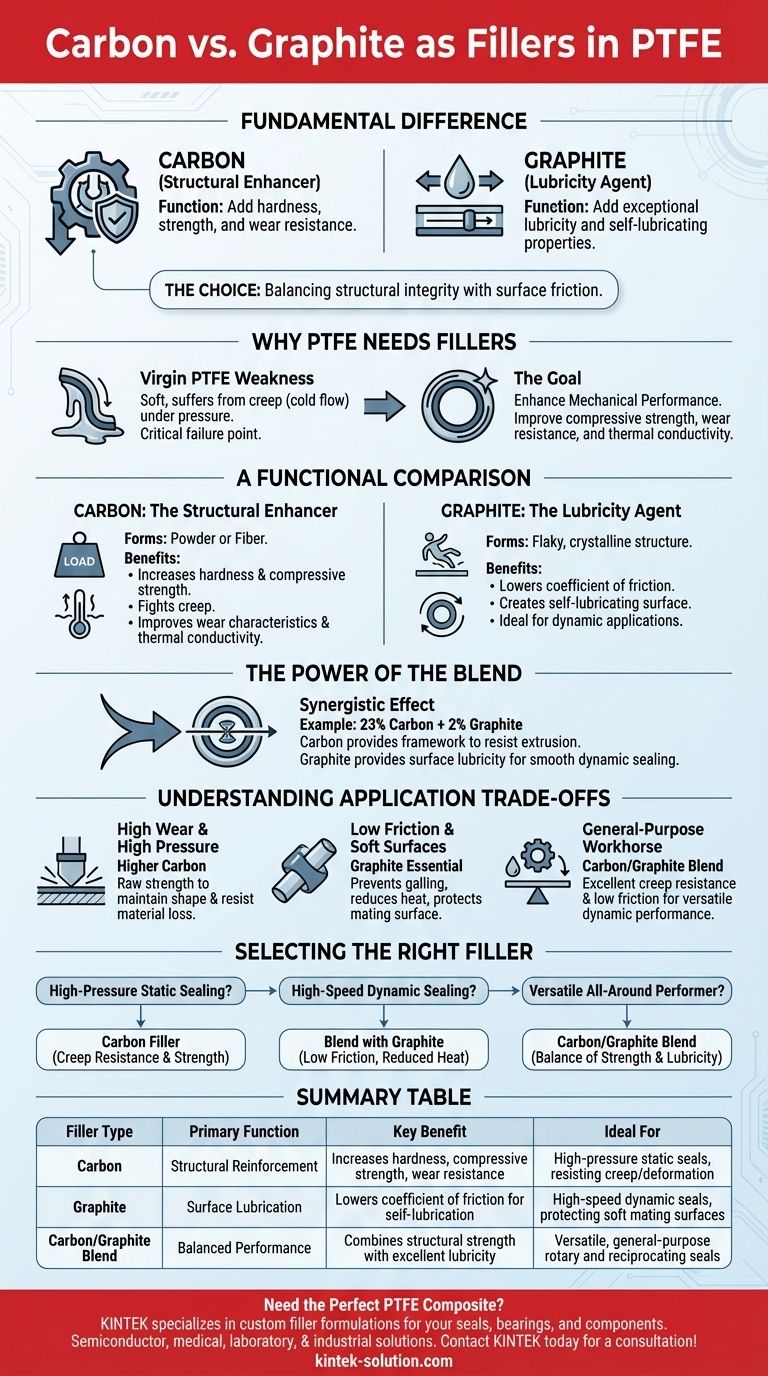

At a fundamental level, the key difference is function. While both carbon and graphite are forms of the same element, they are added to Polytetrafluoroethylene (PTFE) to solve different problems. Carbon filler is primarily used to add hardness, strength, and wear resistance. Graphite, a specific crystalline form of carbon, is added for its exceptional lubricity and self-lubricating properties.

The choice isn't about carbon or graphite; it's about balancing structural integrity with surface friction. Carbon provides the mechanical backbone to resist deformation, while graphite acts as a solid lubricant to ensure smooth, low-friction operation.

Why PTFE Needs Fillers in the First Place

The Weakness of Virgin PTFE

Virgin PTFE is an outstanding material for chemical resistance and its low coefficient of friction. However, it is mechanically soft.

Under pressure, especially over time, it suffers from creep, also known as "cold flow." This means it slowly deforms, which is a critical failure point for components like seals and bearings.

The Goal: Enhancing Mechanical Performance

Fillers are added to the PTFE matrix to combat these weaknesses. They drastically improve key properties like compressive strength, wear resistance, and thermal conductivity, making the material suitable for demanding mechanical applications.

A Functional Comparison: Carbon vs. Graphite

Carbon: The Structural Enhancer

Carbon is typically added as a powder or fiber. Its primary role is to create a much more robust and dimensionally stable composite.

Adding carbon filler significantly increases hardness and compressive strength, which directly fights the tendency of PTFE to creep under load. It also improves wear characteristics and thermal conductivity, helping to dissipate heat from the system.

Graphite: The Lubricity Agent

Graphite is a specific allotrope (a distinct structural form) of carbon. It has a flaky, crystalline structure that easily shears, making it an excellent solid lubricant.

When added to PTFE, graphite's main purpose is to lower the coefficient of friction even further than that of virgin PTFE. This creates a self-lubricating surface ideal for dynamic applications, reducing wear on both the seal and the mating surface.

The Power of the Blend

In many applications, especially rotary shaft seals, carbon and graphite are used together in a specific ratio, such as 23% carbon and 2% graphite.

This blend creates a synergistic effect. The carbon provides the structural framework to resist extrusion and deformation, while the small amount of graphite provides the necessary surface lubricity for smooth, long-lasting dynamic sealing.

Understanding the Application Trade-offs

High Wear and High Pressure

In applications where the primary concern is high contact pressure or wear from an abrasive medium, a higher concentration of carbon is beneficial. It provides the raw strength needed to maintain the component's shape and resist material loss.

Low Friction and Soft Mating Surfaces

For high-speed dynamic seals or when the component runs against a softer metal shaft, graphite is essential. Its lubricating properties prevent galling, reduce frictional heat buildup, and protect the softer mating surface from abrasion. A pure carbon-filled PTFE might be too abrasive in this scenario.

The General-Purpose Workhorse

The common carbon/graphite blend is engineered to be a versatile solution. It offers excellent creep resistance for holding a seal under pressure while ensuring low friction for efficient dynamic performance, making it the default choice for a wide range of applications.

Selecting the Right Filler for Your Application

Choosing the correct filler composition is critical to the performance and longevity of your component.

- If your primary focus is high-pressure static sealing: A higher concentration of carbon filler will provide the necessary creep resistance and compressive strength.

- If your primary focus is high-speed dynamic sealing: A blend containing graphite is non-negotiable to ensure low friction, reduce heat buildup, and protect the mating surface.

- If you need a versatile, all-around performer: The standard carbon/graphite blend offers an excellent balance of strength and lubricity for most general-purpose rotary and reciprocating seals.

Ultimately, selecting the right filler is about matching the material's properties to the specific mechanical and thermal demands of your system.

Summary Table:

| Filler Type | Primary Function | Key Benefit | Ideal For |

|---|---|---|---|

| Carbon | Structural Reinforcement | Increases hardness, compressive strength, and wear resistance | High-pressure static seals, resisting creep/deformation |

| Graphite | Surface Lubrication | Lowers coefficient of friction for self-lubrication | High-speed dynamic seals, protecting soft mating surfaces |

| Carbon/Graphite Blend | Balanced Performance | Combines structural strength with excellent lubricity | Versatile, general-purpose rotary and reciprocating seals |

Need the Perfect PTFE Composite for Your Application?

Choosing the right filler is critical for the performance and longevity of your seals, bearings, and components. The experts at KINTEK specialize in manufacturing precision PTFE components with custom filler formulations—from carbon for strength to graphite for lubricity, and everything in between.

We serve the semiconductor, medical, laboratory, and industrial sectors, offering custom fabrication from prototypes to high-volume orders. Let us help you optimize your design for superior wear resistance, reduced friction, and long-term reliability.

Contact KINTEK today for a consultation and quote!

Visual Guide

Related Products

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What makes the PTFE bottle durable? Unmatched Chemical & Thermal Stability for Demanding Applications

- How do PTFE properties benefit butterfly valve performance? Enhance Durability & Efficiency

- What are the key features of PTFE-lined bottle caps? Ensure Chemical Integrity and Purity for Your Samples

- How does PTFE react to ammonia? Discover Its Superior Chemical Resistance

- What are the chemical resistance properties of PTFE labware? The Ultimate Guide to Inert Labware