The development history of PTFE seals is not marked by a single invention, but by a continuous evolution. This progression was driven by the need to solve sealing challenges—specifically in extreme chemical and temperature environments—that traditional elastomer materials like rubber simply could not handle.

The story of the PTFE seal is one of problem-solving. Its development was a direct response to the failure points of conventional seals, leveraging Polytetrafluoroethylene's unique properties to create a new class of high-performance solutions for the industry's most demanding applications.

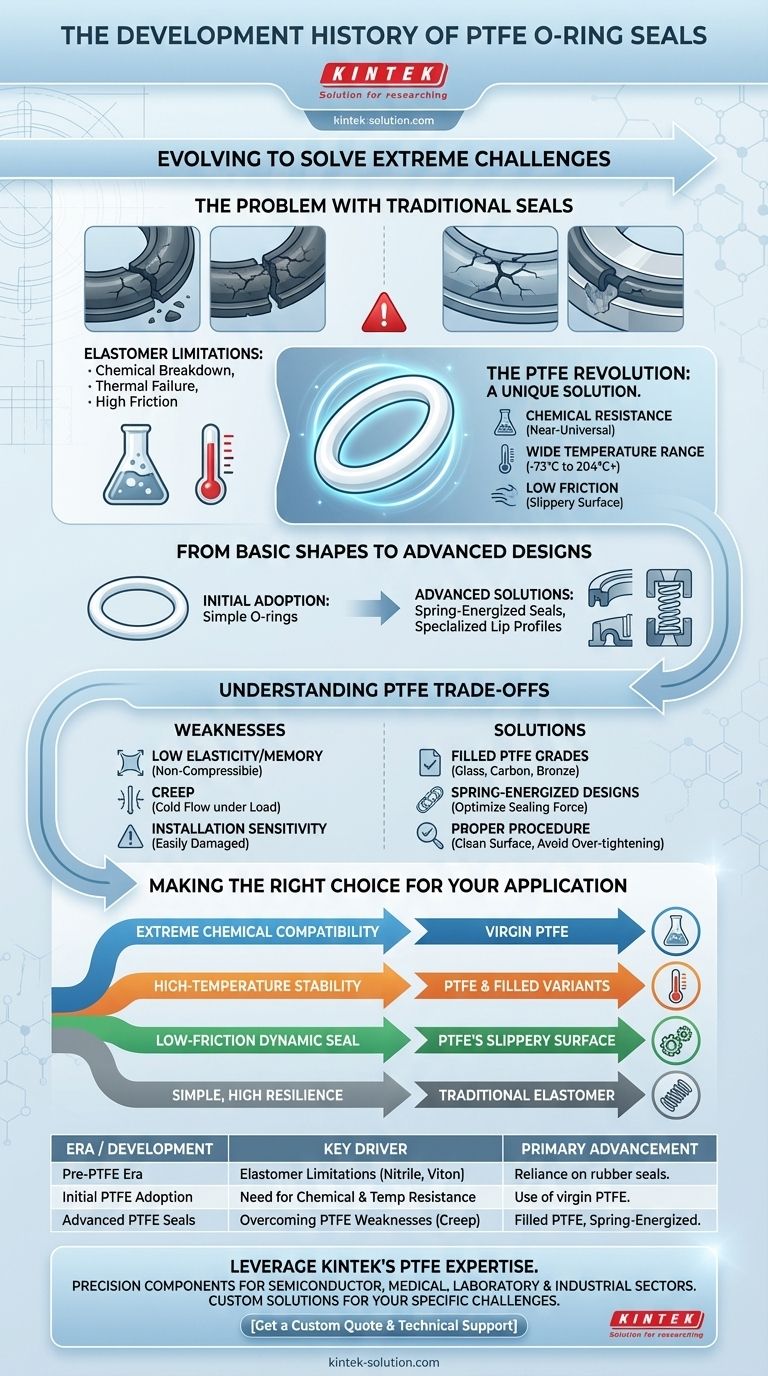

The Problem with Traditional Seals

Before the widespread adoption of PTFE, engineers relied almost exclusively on elastomeric seals, such as Nitrile (Buna-N) and Viton. While effective in many scenarios, they have inherent limitations that created persistent engineering challenges.

The Limits of Elastomers

Traditional rubber compounds degrade when exposed to aggressive chemicals or extreme temperatures. This chemical breakdown or thermal failure results in seal failure, leaks, and costly downtime.

The Challenge of High Friction

In dynamic applications (where parts are moving against the seal), the higher friction of elastomers can lead to significant wear, heat generation, and increased energy consumption over the service life of the equipment.

The Rise of PTFE as a Sealing Solution

The introduction of PTFE provided a material with a combination of properties that directly addressed the weaknesses of traditional elastomers. This sparked an evolution in seal design and capability.

A Material with Unique Properties

PTFE, known for its white color, is a fluoropolymer with an extraordinary set of characteristics. It offers near-universal chemical resistance, remaining stable against almost all industrial acids, solvents, and oils.

It also has a remarkably wide operating temperature range, performing reliably from cryogenic conditions (-73°C) up to high heat (204°C and beyond). Critically, it possesses an extremely low coefficient of friction, making it one of the most slippery materials known.

From Basic Shapes to Advanced Designs

The initial application of PTFE was in simple O-ring configurations. However, engineers quickly realized that while the material properties were exceptional, the physical design needed to be adapted to its unique nature.

This led to the development of high-performance solutions, such as spring-energized seals and specialized lip seal profiles, designed to optimize sealing force and compensate for PTFE's inherent material properties.

Understanding the Trade-offs of PTFE

No material is perfect, and becoming an effective technical professional requires understanding a material's weaknesses as well as its strengths. The unique properties of PTFE introduce specific design and installation considerations.

Low Elasticity and Memory

Unlike rubber, PTFE is not a true elastomer. It is non-compressible and has very poor elastic memory, meaning it does not "spring back" to its original shape well after being compressed. This can be a liability in applications requiring high resilience.

Susceptibility to Creep

Under sustained load and temperature, pure PTFE can be prone to "creep," or cold flow, where the material slowly deforms over time. This challenge was largely solved by the development of filled PTFE grades, which incorporate materials like glass, carbon, or bronze to improve wear resistance and dimensional stability.

Installation Sensitivity

The relative softness of PTFE makes it susceptible to damage during installation. Proper procedure is critical. The sealing surface must be perfectly clean, and care must be taken to avoid over-tightening, which can deform the seal and compromise its integrity.

Making the Right Choice for Your Application

Understanding this development path allows you to select the right material based on your primary engineering goal.

- If your primary focus is extreme chemical compatibility: Virgin PTFE is often the default choice due to its near-total chemical inertness.

- If your primary focus is high-temperature stability: PTFE and its filled variants provide a reliable sealing solution where most elastomers would fail.

- If your primary focus is a low-friction dynamic seal: PTFE's slippery surface is a significant advantage for reducing wear and energy consumption in moving applications.

- If your primary focus is a simple, static seal with high resilience: A traditional elastomer may be a more suitable and cost-effective choice, assuming temperature and media are compatible.

By appreciating its history, you can leverage PTFE's powerful advantages while strategically mitigating its inherent limitations.

Summary Table:

| Era / Development | Key Driver | Primary Advancement |

|---|---|---|

| Pre-PTFE Era | Limitations of Elastomers (Nitrile, Viton) | Reliance on rubber seals; issues with chemical/temperature degradation and high friction. |

| Initial PTFE Adoption | Need for Chemical & Temperature Resistance | Use of virgin PTFE for its inertness and wide temperature range (-73°C to 204°C+). |

| Advanced PTFE Seals | Overcoming PTFE's Weaknesses (Creep, Low Elasticity) | Development of filled PTFE grades and spring-energized designs for improved performance. |

Leverage the Full Potential of PTFE Seals with KINTEK

Understanding the development history of PTFE seals is key to selecting the right solution for your most demanding applications. At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise allows us to help you navigate the trade-offs of PTFE, ensuring you get a seal that delivers superior chemical resistance, temperature stability, and low friction, while mitigating challenges like creep and installation sensitivity.

Whether you need a custom prototype or a high-volume order, our commitment to precision production ensures reliability and performance. Contact us today to discuss how our PTFE solutions can solve your specific sealing challenges and enhance your equipment's efficiency and longevity.

Get a Custom Quote & Technical Support

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications