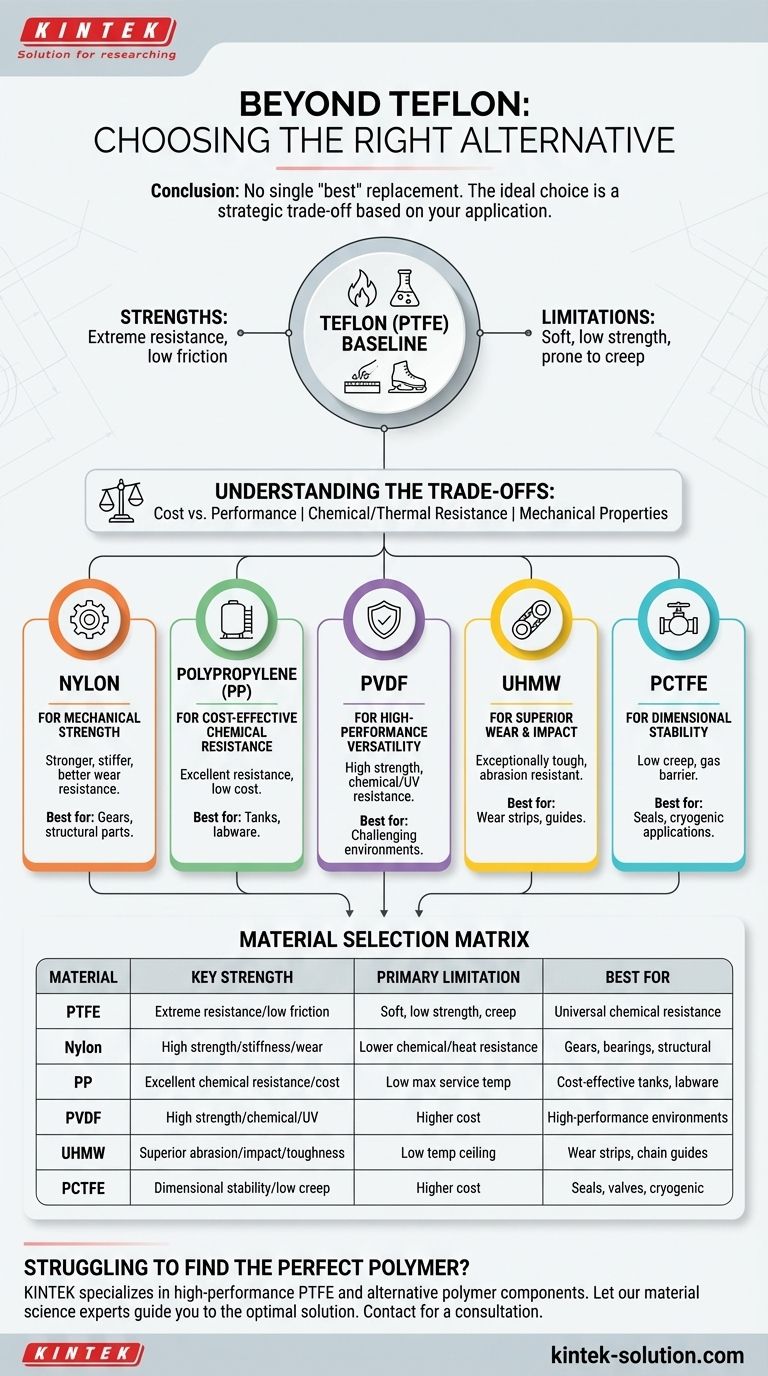

The primary conclusion is that there is no single "best" alternative to Teflon (PTFE). Instead, a range of specialized polymers like PVDF, UHMW, nylon, and polypropylene offer superior performance in specific areas such as rigidity, cost, or wear resistance. The ideal choice is entirely dependent on the application's unique demands.

Choosing a Teflon alternative is a process of strategic trade-offs. While Teflon offers exceptional chemical and thermal resistance, other materials provide significant advantages in mechanical strength, cost-effectiveness, and dimensional stability that may be critical for your specific engineering goal.

Understanding Teflon's (PTFE) Core Profile

To select the right alternative, we must first use Teflon, or Polytetrafluoroethylene (PTFE), as our baseline for comparison. It is a semi-crystalline thermoplastic known for a unique combination of properties.

Key Strengths of PTFE

PTFE is specified for its extremely low coefficient of friction, making it one of the most slippery materials known. It also boasts outstanding chemical inertness and a very high temperature tolerance.

Common Limitations

The primary drivers for seeking an alternative are PTFE’s mechanical weaknesses. It is a relatively soft material with low strength, poor wear resistance, and a tendency to deform under a sustained load, a property known as "creep."

Evaluating the Leading Alternatives

Each alternative material excels where Teflon falls short, offering a different balance of cost, strength, and resistance.

For Enhanced Mechanical Strength: Nylon

Nylon is significantly stronger, stiffer, and has better wear resistance than PTFE. It is an excellent choice for structural components like gears or bearings where mechanical integrity is paramount.

However, it has much lower resistance to chemicals and high temperatures compared to PTFE.

For Cost-Effective Chemical Resistance: Polypropylene (PP)

Polypropylene provides excellent resistance to a wide range of acids and bases at a fraction of the cost of PTFE. This makes it a go-to material for chemical tanks and lab equipment.

Its main limitation is a much lower maximum service temperature.

For High-Performance Versatility: PVDF

PVDF (Polyvinylidene Fluoride) is a fluoropolymer like PTFE but offers far greater mechanical strength, stiffness, and resistance to creep. It retains excellent chemical and UV resistance, making it a high-performance choice for challenging environments where mechanical properties matter.

For Superior Wear and Impact Resistance: UHMW

UHMW (Ultra-High Molecular Weight Polyethylene) is exceptionally tough and has outstanding resistance to abrasion and impact. Its low friction and high durability make it ideal for wear strips, chain guides, and other high-wear industrial applications.

Like polypropylene, its temperature ceiling is significantly lower than that of PTFE.

For Dimensional Stability: PCTFE

PCTFE (Polychlorotrifluoroethylene) is another fluoropolymer that stands out for its rigidity and dimensional stability. It exhibits very low creep and is an excellent barrier against gas and moisture, making it ideal for seals, valves, and cryogenic applications.

Understanding the Trade-offs

Selecting the right material requires a clear understanding of the compromises involved with each choice.

Cost vs. Performance

There is a direct correlation between price and performance. Materials like Polypropylene offer tremendous value for less demanding applications, while high-performance fluoropolymers like PVDF and PCTFE carry a significant cost premium.

Chemical and Thermal Resistance

While PTFE has an almost universal chemical resistance, you may only need resistance to a specific substance. An alternative like polypropylene might be perfectly sufficient and far more economical if it meets the needs of your specific environment.

The Importance of Mechanical Properties

Teflon's softness is often its biggest drawback. For any application where the component is under a constant load or subject to wear, mechanical properties like rigidity and tensile strength should be the primary decision criteria.

Making the Right Choice for Your Goal

Define your most critical requirement to quickly narrow down the best material for your needs.

- If your primary focus is extreme chemical and heat resistance: Teflon (PTFE) remains the benchmark, but consider PVDF for added mechanical strength.

- If your primary focus is mechanical strength and wear resistance: Nylon or UHMW are likely the most effective and economical choices.

- If your primary focus is balancing cost and general chemical resistance: Polypropylene offers a compelling and highly cost-effective solution for moderate temperature ranges.

- If your primary focus is dimensional stability under load: PCTFE is the superior option, especially in applications requiring low deformation or superior moisture barrier properties.

Ultimately, the best material is the one that precisely matches the mechanical, chemical, and economic requirements of your specific application.

Summary Table:

| Material | Key Strengths | Primary Limitations | Best For |

|---|---|---|---|

| PTFE (Teflon) | Extreme chemical/heat resistance, low friction | Soft, low strength, prone to creep | Universal chemical resistance |

| Nylon | High mechanical strength, stiffness, wear resistance | Lower chemical/heat resistance | Gears, bearings, structural parts |

| Polypropylene (PP) | Excellent chemical resistance, low cost | Low maximum service temperature | Cost-effective tanks, labware |

| PVDF | High mechanical strength, good chemical/UV resistance | Higher cost than PTFE | High-performance, challenging environments |

| UHMW | Superior abrasion/impact resistance, toughness | Low temperature ceiling | Wear strips, chain guides |

| PCTFE | Excellent dimensional stability, low creep, gas barrier | Higher cost | Seals, valves, cryogenic applications |

Struggling to find the perfect polymer for your component?

At KINTEK, we specialize in manufacturing high-performance PTFE and alternative polymer components (seals, liners, labware, and more) for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get a component that perfectly balances mechanical properties, chemical resistance, and cost for your unique application.

Let our material science experts guide you to the optimal solution. Contact KINTEK today for a consultation!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why are PTFE expansion joints particularly suitable for the chemical industry? Ensure Leak-Free, Corrosion-Resistant Piping

- How does PTFE coating enhance corrosion resistance in fasteners? Achieve Unmatched Protection in Harsh Environments

- What are the advantages of PTFE-coated O-rings? Reduce Friction & Color-Code for Easy Assembly

- Which substances is PTFE not chemically resistive to? Avoid These Extreme Conditions

- In what applications are PTFE slide bearings superior to conventional supports? Ensuring Predictable Movement for Critical Structures

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What guidelines apply to machining oil grooves in PTFE pads? Achieve Precision & Avoid Common Pitfalls

- What are some common applications of PTFE Expansion Bellows? Solve Corrosion, Temperature, and Vibration Challenges