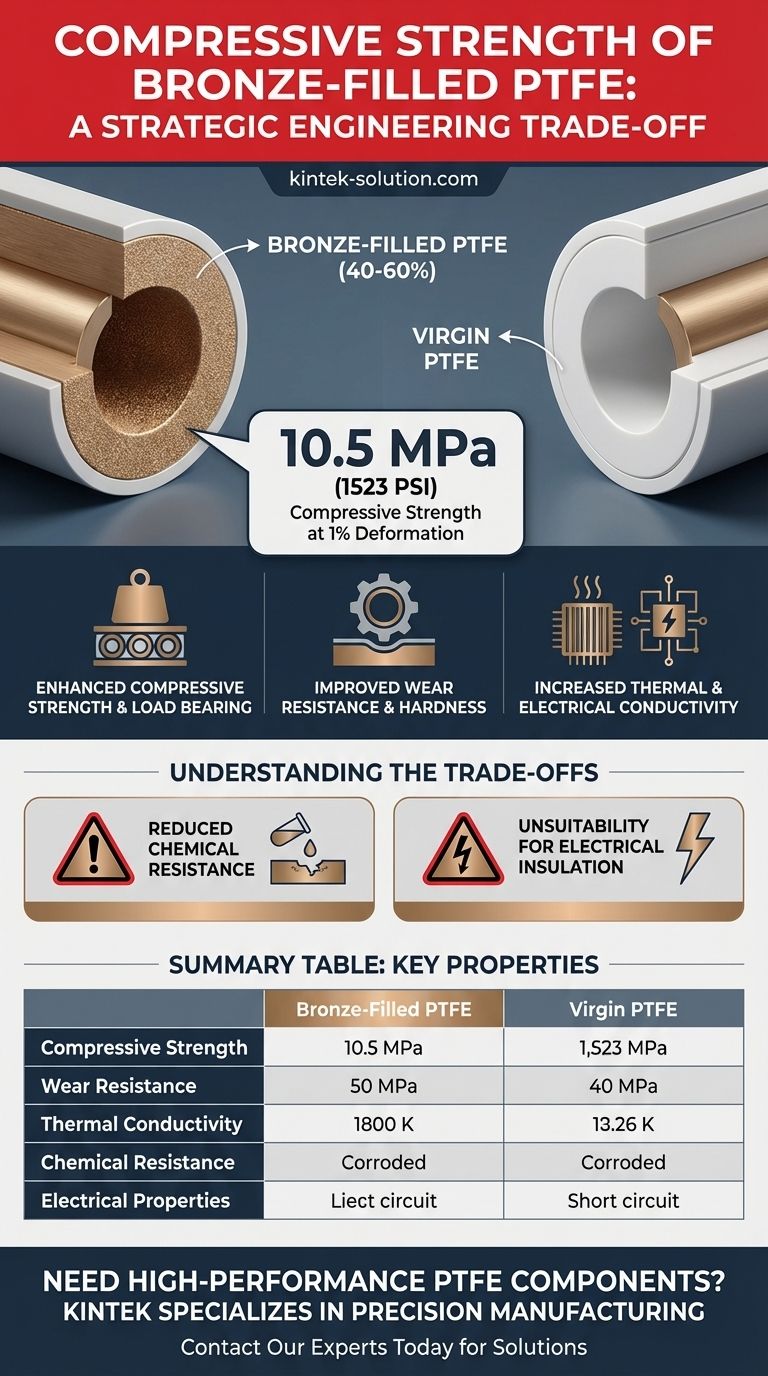

The short answer is that 40-60% bronze-filled Polytetrafluoroethylene (PTFE) has a compressive strength of approximately 10.5 MPa (1523 PSI) at 1% deformation. This value highlights a significant improvement over unfilled PTFE, which is notoriously soft and prone to deforming under load. The addition of bronze fundamentally transforms the material's mechanical capabilities.

The core takeaway is that adding bronze filler to PTFE is a strategic engineering trade-off. You gain significant improvements in compressive strength, wear resistance, and thermal conductivity, making it ideal for mechanical applications. However, this comes at the direct cost of PTFE's hallmark chemical inertness and electrical insulation properties.

Why Add Bronze to PTFE?

Unfilled, or "virgin," PTFE is an exceptional polymer known for its chemical resistance and low friction. However, it suffers from poor mechanical properties, specifically creep (or "cold flow"), where it slowly deformes under sustained pressure.

Adding bronze particles as a filler material directly addresses these mechanical weaknesses.

Enhanced Compressive Strength and Load Bearing

The primary benefit of the bronze filler is a dramatic increase in compressive strength. The small, hard bronze particles distributed throughout the PTFE matrix act as a reinforcing agent.

This reinforcement prevents the softer PTFE polymer from flowing or deforming under load. It makes the material suitable for high-load applications like bearings, bushings, and wear rings where virgin PTFE would quickly fail.

Improved Wear Resistance and Hardness

Along with compressive strength, bronze significantly increases the hardness and wear resistance of the composite. This makes it highly durable in dynamic, high-friction scenarios.

The material can withstand abrasion far better than unfilled PTFE, leading to a longer service life for components like piston seals and slide pads.

Increased Thermal and Electrical Conductivity

Virgin PTFE is an excellent thermal and electrical insulator. The addition of metallic bronze particles creates a pathway for heat to dissipate, resulting in high thermal conductivity.

This property is crucial in high-speed bearing applications where friction generates heat that must be drawn away to prevent failure. This same property, however, also makes it electrically conductive, unlike pure PTFE.

Understanding the Trade-offs

The enhanced mechanical properties of bronze-filled PTFE do not come without compromises. Understanding these limitations is critical for proper material selection.

Reduced Chemical Resistance

The most significant trade-off is a loss of chemical inertness. While PTFE itself is resistant to nearly all chemicals, bronze is not.

The composite material is vulnerable to certain acids, alkalis, and corrosive environments that would have no effect on virgin PTFE. This makes it unsuitable for applications with aggressive chemical exposure.

Unsuitability for Electrical Insulation

Because the bronze filler makes the material conductive, it is completely unsuitable for applications requiring electrical insulation.

Engineers often choose virgin PTFE for its excellent dielectric properties. Choosing a bronze-filled variant for such an application would lead to immediate system failure.

Compromised Non-Stick Properties

While still possessing a low coefficient of friction, the bronze particles do disrupt the famously non-stick surface of pure PTFE. The surface is harder and slightly more abrasive than that of its unfilled counterpart.

Making the Right Choice for Your Application

Selecting the correct material requires aligning its properties with your primary engineering goal.

- If your primary focus is mechanical performance: Bronze-filled PTFE is an excellent choice for high-load bearings, bushings, and wear components where strength and thermal dissipation are critical.

- If your primary focus is chemical inertness: You must avoid bronze-filled PTFE and instead consider virgin PTFE or one filled with a more inert material like glass or carbon.

- If your primary focus is electrical insulation: Bronze-filled PTFE must not be used. Virgin PTFE is the appropriate choice for its high dielectric strength.

Ultimately, bronze-filled PTFE should be viewed as a high-strength mechanical material, not as a chemically resistant or electrically insulating one.

Summary Table:

| Property | Bronze-Filled PTFE (40-60%) | Virgin (Unfilled) PTFE |

|---|---|---|

| Compressive Strength (1% deformation) | ~10.5 MPa (1523 PSI) | Very Low (Prone to Creep) |

| Wear Resistance & Hardness | High | Low |

| Thermal Conductivity | High (Good for heat dissipation) | Low (Excellent Insulator) |

| Chemical Resistance | Reduced (Vulnerable to corrosives) | Exceptional |

| Electrical Properties | Conductive | Excellent Insulator |

Need high-performance PTFE components that can handle heavy loads?

At KINTEK, we specialize in precision manufacturing of bronze-filled PTFE components like seals, bushings, and bearings. We understand the critical balance between mechanical strength, wear resistance, and environmental factors for applications in the semiconductor, medical, laboratory, and industrial sectors.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications for performance and durability.

Contact our experts today to discuss how our bronze-filled PTFE solutions can solve your specific engineering challenges.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why are PTFE bushes considered indispensable in modern industrial applications? Achieve Unmatched Reliability

- How can burr formation be minimized in PTFE machining? A Guide to Clean, Accurate Parts

- What are the primary materials used for oil seals? NBR vs. PTFE for Your Application

- What are the key features and benefits of PTFE envelope gaskets? Achieve Superior Sealing in Corrosive Environments

- How is PTFE's low friction property utilized in industrial applications? Boost Efficiency & Reduce Wear

- What are the physical properties of PTFE balls? A Guide to Extreme Chemical & Thermal Performance

- What are some challenges in CNC machining Teflon? Mastering Material Instability for Precision Parts

- Can PTFE coating thrust washers be used in saltwater fishing? Key Considerations for Marine Durability