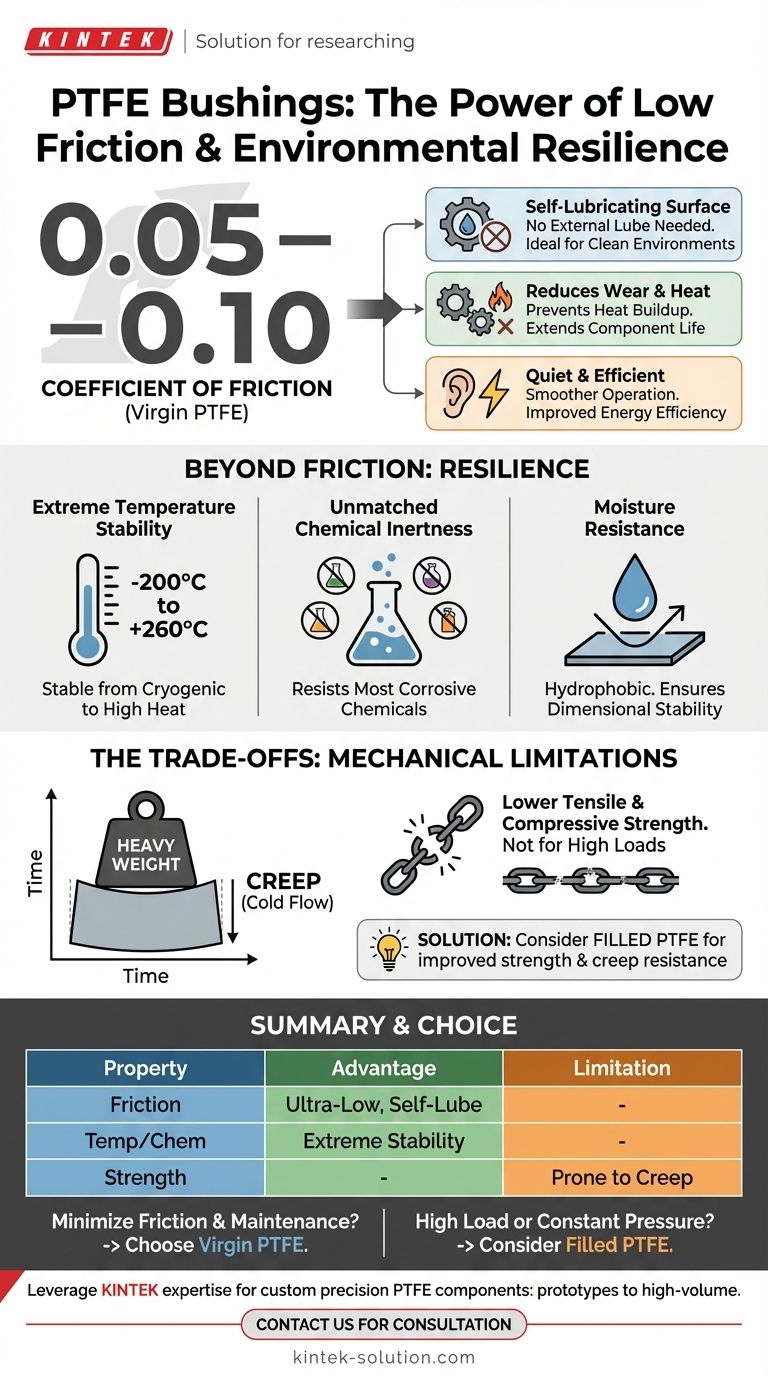

The coefficient of friction for virgin Polytetrafluoroethylene (PTFE) is remarkably low, typically cited between 0.05 and 0.10. This value is one of the lowest recorded for any solid material. This exceptional slipperiness is the primary reason PTFE is a superior material for bushings, as it creates a self-lubricating surface that drastically reduces wear, heat generation, and the need for external lubricants.

PTFE's value in bushings isn't just its exceptionally low friction, but its unique combination of self-lubrication, extreme temperature tolerance, and chemical inertness. However, this performance comes with a critical trade-off: a lower mechanical strength and susceptibility to deformation under load.

The Core Advantage: An Exceptionally Low Coefficient of Friction

The primary function of a bushing is to provide a low-wear surface for rotating or sliding parts. PTFE's fundamental properties are uniquely suited for this task.

Defining the Friction Value

Virgin PTFE consistently exhibits a static and dynamic coefficient of friction in the 0.05 to 0.10 range. Some test methods may yield results as low as 0.02, but the 0.05-0.10 range is the accepted standard for engineering applications.

The Impact on Heat and Wear

Friction is the direct cause of heat generation and mechanical wear in moving systems. By minimizing friction, PTFE bushings prevent significant heat buildup, allowing for higher operational speeds and reducing material degradation over time.

The Self-Lubricating Effect

PTFE's low friction means it does not require external grease or oil to operate smoothly. This self-lubricating characteristic is ideal for applications where maintenance is difficult or where lubricants could contaminate the product, such as in food or pharmaceutical processing.

Quiet Operation and Energy Efficiency

Systems using PTFE bushings operate more quietly because there is less resistance between moving parts. This same principle also improves energy efficiency, as less power is wasted overcoming friction.

Beyond Friction: The Environmental Resilience of PTFE

While low friction is the headline feature, PTFE's ability to withstand harsh conditions makes it a robust engineering choice.

Extreme Temperature Stability

Virgin PTFE maintains its properties across a vast temperature range, remaining stable from approximately -200°C to +260°C (-328°F to +500°F). This allows its use in cryogenic applications as well as high-temperature environments without degradation.

Unmatched Chemical Inertness

PTFE is almost completely inert and will not react with the vast majority of industrial chemicals, solvents, or acids. This makes PTFE bushings the default choice for equipment used in corrosive chemical processing.

Resistance to Moisture

PTFE is hydrophobic and does not absorb water. This property prevents the material from swelling or degrading in humid or wet environments, ensuring dimensional stability.

Understanding the Trade-offs: Mechanical Limitations

No material is perfect. The same molecular structure that gives PTFE its desirable properties also introduces critical mechanical weaknesses.

The Problem of "Creep" or Cold Flow

The most significant limitation of virgin PTFE is its susceptibility to creep, also known as cold flow. Under a constant compressive load, the material will slowly deform over time, even at room temperature.

Lower Tensile and Compressive Strength

Compared to metals or even other engineering plastics, virgin PTFE is a relatively soft material with low tensile strength. It is not suitable for high-load, structural applications where maintaining precise dimensions under pressure is critical.

The Role of Fillers

To counteract these mechanical weaknesses, PTFE is often blended with additives like glass fiber, carbon, or bronze. These "filled PTFE" variants offer significantly improved creep resistance and strength, though often with a slight increase in the coefficient of friction.

Making the Right Choice for Your Application

Selecting virgin PTFE for a bushing requires balancing its unique benefits against its mechanical limitations.

- If your primary focus is minimizing friction and maintenance: Virgin PTFE is an ideal choice, especially in clean environments or for high-speed, low-load scenarios.

- If your application involves extreme temperatures or harsh chemicals: Virgin PTFE's thermal stability and chemical inertness provide a significant advantage over almost any other material.

- If your application involves high structural loads or constant pressure: You must account for virgin PTFE's tendency to creep and strongly consider filled PTFE grades or alternative materials.

Understanding these distinct properties is the key to correctly leveraging PTFE's unique strengths in your design.

Summary Table:

| Property | Value / Characteristic | Key Advantage for Bushings |

|---|---|---|

| Coefficient of Friction | 0.05 - 0.10 | Extremely low sliding resistance, self-lubricating |

| Temperature Range | -200°C to +260°C | Stable performance in extreme environments |

| Chemical Resistance | Highly inert | Ideal for corrosive or clean environments |

| Key Limitation | Low mechanical strength, prone to creep | Requires careful design for load-bearing applications |

Leverage the exceptional properties of PTFE for your next project.

At KINTEK, we specialize in the precision manufacturing of high-performance PTFE components, including custom bushings, seals, and labware. Whether you need the ultra-low friction of virgin PTFE or the enhanced strength of filled compounds, our expertise ensures a solution tailored to your specific requirements in the semiconductor, medical, laboratory, or industrial sectors.

Let's discuss how our custom fabrication—from prototypes to high-volume orders—can solve your unique challenges. Contact our team today for a consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments