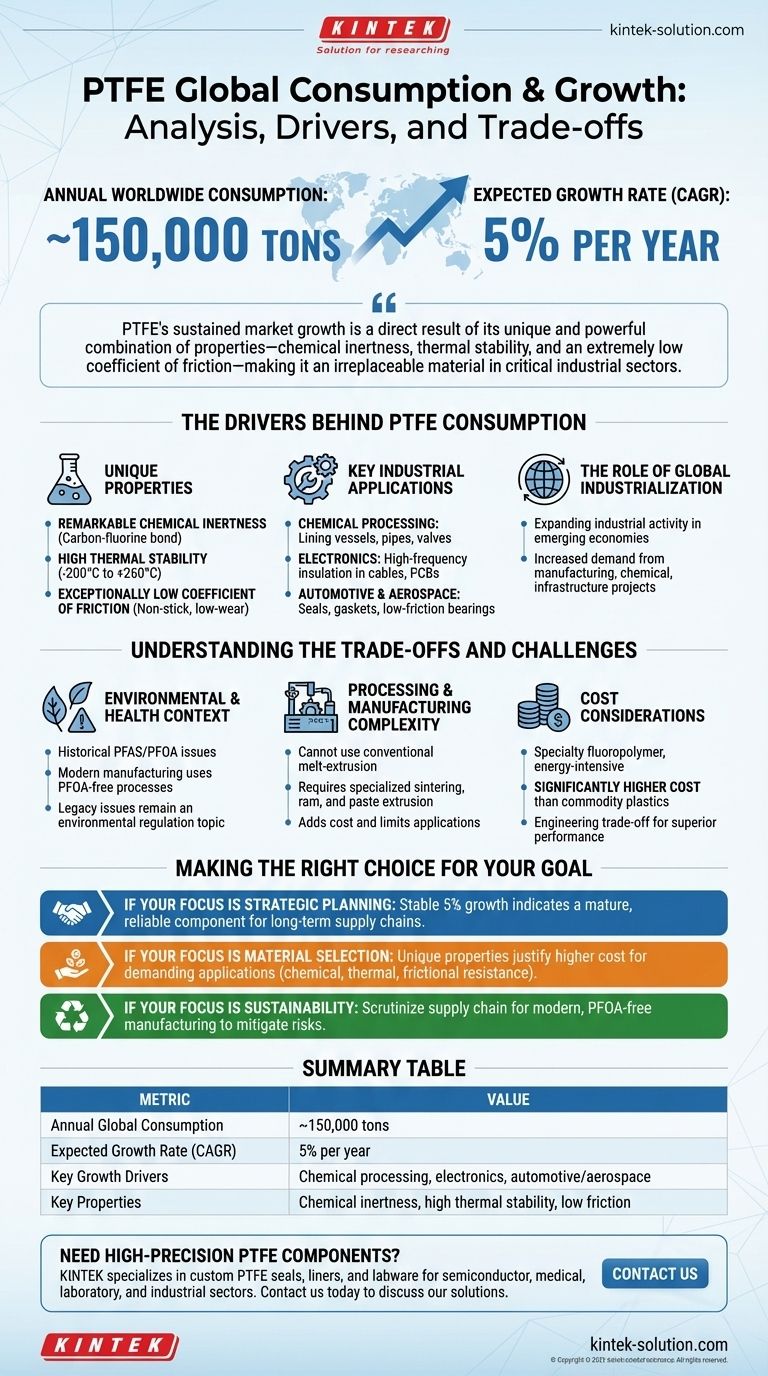

To be direct, the annual worldwide consumption of Polytetrafluoroethylene (PTFE) is approximately 150,000 tons. The market for this high-performance polymer is expected to expand at a steady compound annual growth rate (CAGR) of 5% per year.

PTFE's sustained market growth is not accidental; it is a direct result of its unique and powerful combination of properties—chemical inertness, thermal stability, and an extremely low coefficient of friction—making it an irreplaceable material in critical industrial sectors.

The Drivers Behind PTFE Consumption

The demand for PTFE is fundamentally tied to its exceptional characteristics, which solve challenges that commodity plastics cannot. This makes it a cornerstone material in numerous high-value applications.

The Unique Properties of PTFE

PTFE, widely known by the brand name Teflon, possesses a rare set of attributes. Its carbon-fluorine bond is one of the strongest in organic chemistry.

This structure gives it remarkable chemical inertness, making it resistant to nearly all corrosive chemicals and solvents.

It also has an extremely high thermal stability, allowing it to perform reliably in environments from -200°C to +260°C.

Finally, its exceptionally low coefficient of friction gives it the non-stick, low-wear surface for which it is famous.

Key Industrial Applications

These properties translate directly into high-stakes industrial uses that fuel its consumption.

In the chemical processing industry, PTFE is used for lining vessels, pipes, and valves to handle corrosive materials safely.

The electronics sector relies on PTFE for high-frequency insulation in cables and printed circuit boards (PCBs) due to its excellent dielectric properties.

In automotive and aerospace, it is essential for seals, gaskets, and low-friction bearings that must withstand extreme temperatures and pressures.

The Role of Global Industrialization

The 5% growth rate is heavily influenced by expanding industrial activity in emerging economies.

As manufacturing, chemical production, and infrastructure projects increase globally, the demand for reliable, high-performance materials like PTFE naturally rises in tandem.

Understanding the Trade-offs and Challenges

While PTFE is a "miracle material" in many respects, a complete understanding requires acknowledging its associated challenges and trade-offs.

Environmental and Health Context

PTFE itself is a stable and inert polymer. However, the historical use of per- and polyfluoroalkyl substances (PFAS), like PFOA, as processing aids in its manufacturing has led to significant environmental and health concerns.

These "forever chemicals" persist in the environment and have been linked to adverse health effects. Modern manufacturing has largely phased out these specific compounds, but the legacy of PTFE production remains a critical topic in environmental regulation.

Processing and Manufacturing Complexity

Unlike many common thermoplastics, PTFE cannot be processed using conventional melt-extrusion or injection molding techniques due to its extremely high melt viscosity.

It requires specialized methods like sintering, ram extrusion, and paste extrusion. This complexity adds to the final component's cost and limits its applications compared to more easily processable polymers.

Cost Considerations

PTFE is a specialty fluoropolymer, and its manufacturing process is more energy-intensive and complex than that of commodity plastics like polyethylene or polypropylene.

Consequently, its cost is significantly higher. The decision to use PTFE is therefore an engineering trade-off, balancing its superior performance against its premium price.

Making the Right Choice for Your Goal

Understanding the consumption and growth data for PTFE allows for better strategic, engineering, and environmental decision-making.

- If your primary focus is strategic planning: The stable 5% growth rate indicates a mature but consistently expanding market, making PTFE a reliable component in long-term industrial supply chains.

- If your primary focus is material selection: PTFE's unique properties justify its higher cost in demanding applications where failure is not an option and chemical, thermal, or frictional resistance is paramount.

- If your primary focus is sustainability: You must scrutinize the supply chain to ensure the PTFE is sourced from manufacturers using modern, PFOA-free processes to mitigate environmental and regulatory risks.

Ultimately, the steady demand for PTFE underscores its critical role as a problem-solving material in modern technology and industry.

Summary Table:

| Metric | Value |

|---|---|

| Annual Global Consumption | ~150,000 tons |

| Expected Growth Rate (CAGR) | 5% per year |

| Key Growth Drivers | Chemical processing, electronics, automotive/aerospace |

| Key Properties | Chemical inertness, high thermal stability, low friction |

Need high-precision PTFE components for your demanding application?

KINTEK specializes in manufacturing custom PTFE seals, liners, and labware for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in processing this complex material ensures you get components that deliver unmatched chemical resistance, thermal stability, and performance—whether you need prototypes or high-volume production.

Contact us today to discuss how our PTFE solutions can enhance your product's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments