Teflon is the well-known brand name for a synthetic polymer called Polytetrafluoroethylene, or PTFE. It is a fluoropolymer composed of carbon and fluorine, renowned for an extraordinary combination of properties including extreme chemical resistance, high-temperature stability, and an exceptionally non-stick surface.

At its core, Teflon's remarkable characteristics all stem from the incredibly strong and stable bonds between its carbon and fluorine atoms. This simple chemical reality makes it one of the most inert, slippery, and thermally resilient materials available for demanding applications.

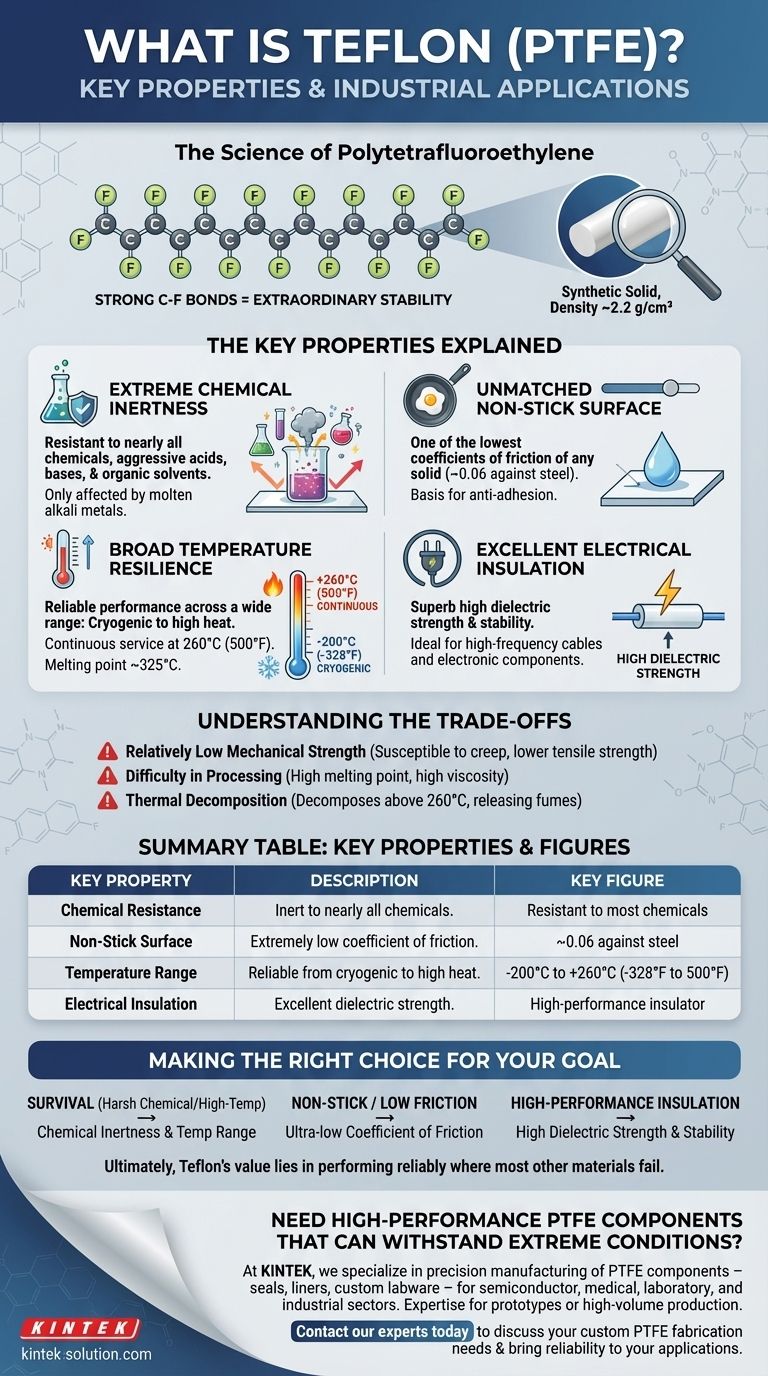

What Defines Teflon (PTFE)?

Teflon is not just one material but a brand name that has become synonymous with its primary polymer, PTFE. Its identity is rooted in its unique chemical structure, which dictates its behavior.

The Chemical Foundation

PTFE is a fluorocarbon-based polymer. This means it consists of a long chain of carbon atoms completely surrounded by fluorine atoms.

The carbon-fluorine bond is one of the strongest in organic chemistry. This immense bond strength is the fundamental reason for PTFE's stability and inertness.

A Synthetic Solid

At room temperature, PTFE is a white, high-density solid. Its density is approximately 2.2 g/cm³, making it significantly heavier than many other plastics.

The Key Properties Explained

The utility of Teflon arises from a set of properties that rarely coexist in a single material. Each one makes it uniquely suited for specific, often extreme, industrial and commercial uses.

Extreme Chemical Inertness

Due to its strong chemical bonds, PTFE is almost completely inert. It is resistant to nearly all chemicals, including aggressive acids, bases, and organic solvents. Only highly reactive alkali metals can affect it.

Unmatched Non-Stick Surface

Teflon has one of the lowest coefficients of friction of any solid material, measured at approximately 0.06 against steel. This "slipperiness" is the basis for its famous non-stick, or anti-adhesion, properties.

Broad Temperature Resilience

PTFE performs reliably across an exceptionally wide temperature range, from cryogenic conditions at -200°C (-328°F) up to continuous service at 260°C (500°F). Its melting point is around 325°C (600°F).

Excellent Electrical Insulation

The stable molecular structure of PTFE makes it a superb electrical insulator with a high dielectric strength. It does not conduct electricity, making it ideal for high-frequency cables and electronic components.

Durability and Resistance

Beyond its primary traits, PTFE exhibits excellent weatherability, non-flammability, and extremely low water absorption (around 0.0074%). This ensures its stability and longevity even when exposed to the elements.

Understanding the Trade-offs

While its properties are exceptional, PTFE is not the solution for every engineering problem. Understanding its limitations is critical for proper application.

Relatively Low Mechanical Strength

Compared to other engineering plastics, PTFE is mechanically soft. It can be susceptible to "creep" (deformation under sustained load) and has lower tensile strength and abrasion resistance.

Difficulty in Processing

The same properties that make PTFE so stable also make it difficult to process. Its high melting point and viscosity mean it cannot be easily injection molded or extruded like common thermoplastics.

Thermal Decomposition

While stable up to 260°C, heating PTFE to significantly higher temperatures can cause it to decompose and release potentially harmful fumes. This is a critical safety consideration, particularly in cookware applications.

Making the Right Choice for Your Goal

Selecting a material depends entirely on the primary challenge you need to solve.

- If your primary focus is survival in harsh chemical or high-temperature environments: Teflon's chemical inertness and wide operating temperature range make it an unparalleled choice.

- If your primary focus is creating a non-stick or low-friction surface: Teflon's extremely low coefficient of friction is its defining characteristic for these applications.

- If your primary focus is high-performance electrical insulation: Teflon's high dielectric strength and stability are ideal for demanding electronics and wiring.

Ultimately, Teflon's value lies in its ability to perform reliably where most other materials fail.

Summary Table:

| Key Property | Description | Key Figure |

|---|---|---|

| Chemical Resistance | Inert to nearly all chemicals, acids, and solvents. | Resistant to most chemicals |

| Non-Stick Surface | Extremely low coefficient of friction. | ~0.06 against steel |

| Temperature Range | Performs reliably from cryogenic to high heat. | -200°C to +260°C (-328°F to 500°F) |

| Electrical Insulation | Excellent dielectric strength and stability. | High-performance insulator |

Need high-performance PTFE components that can withstand extreme conditions?

At KINTEK, we specialize in the precision manufacturing of PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume production, our expertise ensures your components meet the highest standards of chemical resistance, thermal stability, and non-stick performance.

Contact our experts today to discuss your custom PTFE fabrication needs and discover how we can bring reliability to your most demanding applications.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech