In short, Polytetrafluoroethylene (PTFE) demonstrates exceptional resistance to a wide range of oils. Its inherent chemical inertness allows it to reliably handle everything from industrial lubricants and diesel fuel to natural vegetable and animal oils. This high level of resistance is maintained across a broad spectrum of operating temperatures.

The core reason for PTFE's outstanding performance is its molecular structure. The powerful carbon-fluorine bonds are non-reactive, making PTFE virtually immune to degradation from the hydrocarbons and additives found in nearly all types of oils.

Why PTFE Excels in Oil-Rich Environments

The reliability of PTFE in contact with oils is not a coincidence; it is a direct result of its fundamental chemical properties. This makes it a primary material choice for critical components like seals, gaskets, and filters in demanding industrial settings.

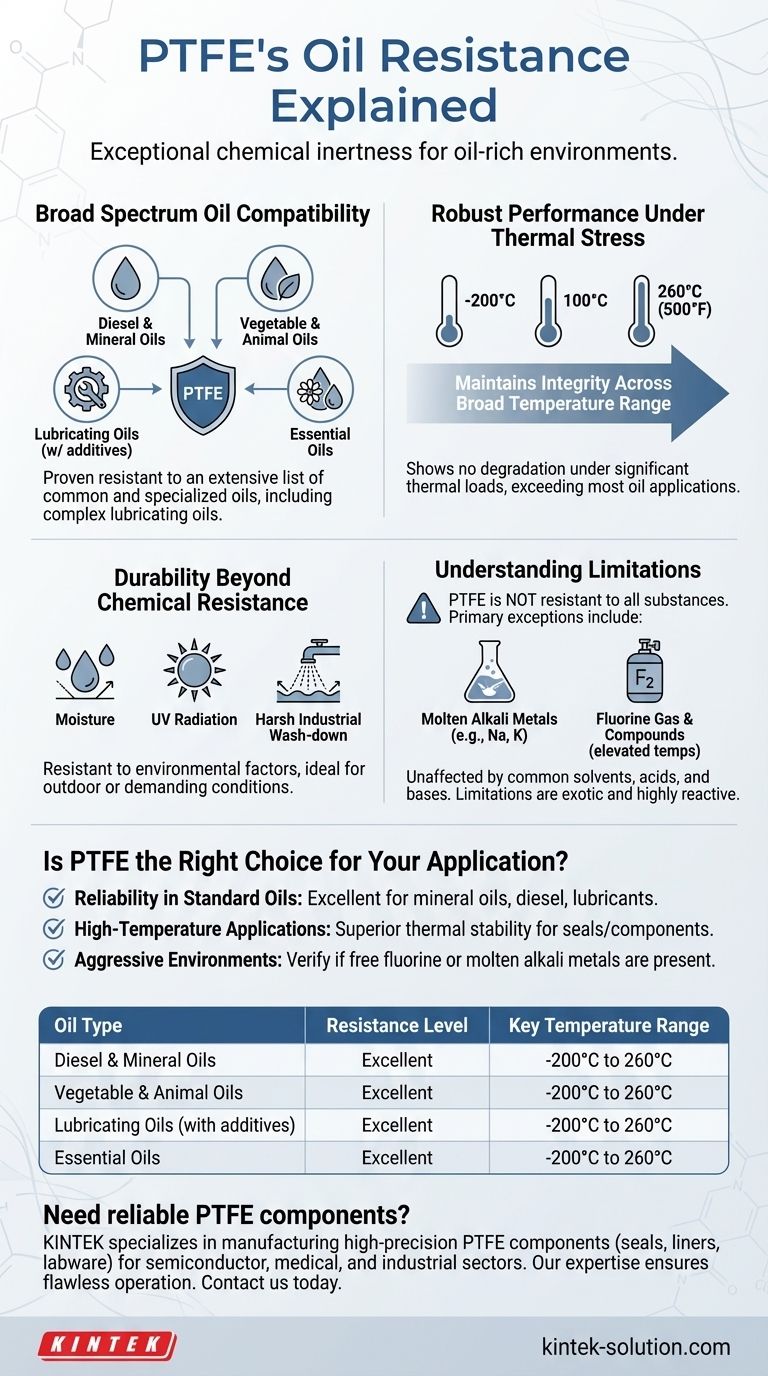

Broad Spectrum Oil Compatibility

PTFE is proven to be fully resistant to an extensive list of common and specialized oils.

This includes diesel oil, mineral oils, essential oils, and both vegetable and animal oils. It also safely handles more complex lubricating oils that contain aromatic additives.

Robust Performance Under Thermal Stress

A material's chemical resistance can change with temperature, but PTFE maintains its integrity under significant thermal loads.

It shows no degradation when exposed to oils at temperatures of 20°C (68°F), 60°C (140°F), and 100°C (212°F). Furthermore, PTFE components can operate in environments up to 260°C (500°F), far exceeding the requirements for most oil applications.

Durability Beyond Chemical Resistance

In many real-world applications, oil is not the only environmental challenge.

PTFE is also highly resistant to moisture, UV radiation, and other environmental factors. This makes it an ideal choice for components used outdoors or in harsh industrial wash-down areas where aggressive cleaning agents might be present.

Understanding PTFE's Chemical Limitations

No material is universally impervious. While PTFE's resistance to oils and common chemicals is nearly absolute, its limitations are found only when exposed to a very specific and highly reactive class of substances.

The Few Exceptions to Inertness

It is crucial to note that PTFE is not resistant to all substances.

The primary exceptions are molten or dissolved alkali metals like sodium and potassium. It can also be attacked by fluorine gas and certain fluorine compounds, particularly at elevated temperatures.

The Principle of Chemical Inertness

The reason PTFE is so robust is that it is unaffected by virtually all common solvents, acids, and bases.

Its limitations are with exotic and highly aggressive chemicals that are not encountered in typical oil-based systems. This is why its performance with oils is so predictable and reliable.

Is PTFE the Right Choice for Your Application?

Choosing the correct material requires matching its properties to the specific demands of the environment. PTFE's profile makes it a straightforward choice for most oil-related challenges.

- If your primary focus is reliability in standard industrial oils: PTFE is an exceptionally safe and durable choice for mineral oils, diesel, and lubricating fluids.

- If your primary focus is applications involving high temperatures: PTFE's high thermal stability makes it a superior option for seals and components in hot-running machinery.

- If your primary focus is an aggressive environment with mixed chemicals: Always verify compatibility if your system contains free fluorine or molten alkali metals, but rest assured regarding oil exposure.

Ultimately, PTFE's chemical makeup makes it one of the most trustworthy and resilient materials available for applications involving oil.

Summary Table:

| Oil Type | Resistance Level | Key Temperature Range |

|---|---|---|

| Diesel & Mineral Oils | Excellent | -200°C to 260°C |

| Vegetable & Animal Oils | Excellent | -200°C to 260°C |

| Lubricating Oils (with additives) | Excellent | -200°C to 260°C |

| Essential Oils | Excellent | -200°C to 260°C |

Need reliable PTFE components for your oil-rich environment?

KINTEK specializes in manufacturing high-precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your equipment operates flawlessly with exceptional chemical resistance and thermal stability.

Contact us today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What is Teflon and what are its alternative names? Understanding PTFE, the Material Behind the Brand

- When was PTFE discovered and developed? The Accidental Invention That Changed Industries

- What is PTFE commonly known as and what type of material is it? A Guide to High-Performance PTFE Properties

- How does PTFE react to common solvents? Discover Its Near-Total Chemical Immunity

- What is PTFE and what class of plastics does it belong to? A Guide to High-Performance Fluoropolymers