Yes, PTFE can be machined and is most commonly known as Teflon. This incredibly versatile polymer is favored for its unique properties, and standard techniques like CNC milling and turning are used to shape it into custom components for a vast range of industrial applications.

While PTFE's softness makes it surprisingly easy to cut, achieving high-precision results is a significant challenge. Success requires a deep understanding of the material's tendency to expand with heat and deform under pressure.

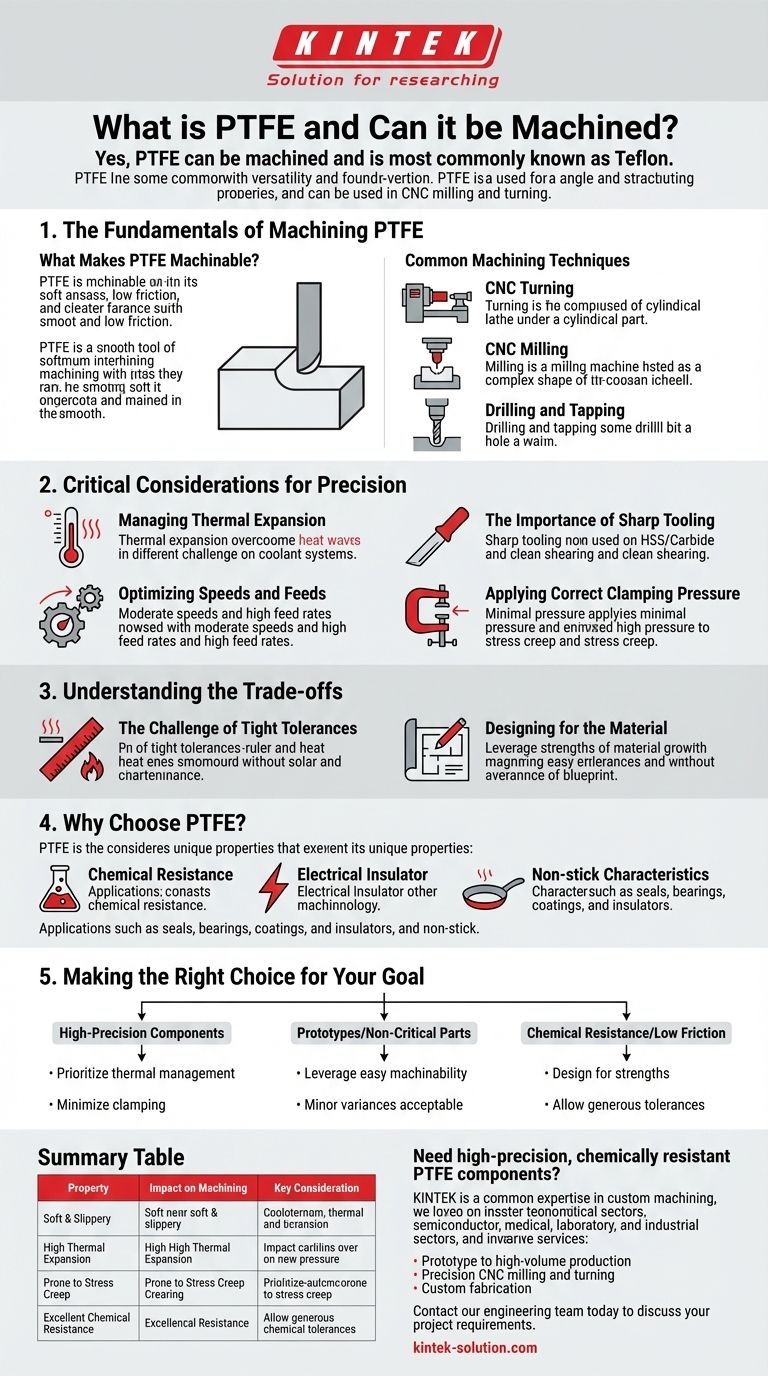

The Fundamentals of Machining PTFE

Polytetrafluoroethylene (PTFE) has a unique set of properties that directly influence how it is machined. Understanding these fundamentals is the first step toward producing quality parts.

What Makes PTFE Machinable?

PTFE is a soft polymer with the lowest coefficient of friction of any known solid. This inherent slipperiness and softness mean that cutting tools can move through the material with relative ease, requiring less force than metals or harder plastics.

Common Machining Techniques

Standard CNC equipment is perfectly suitable for processing PTFE. The specific method depends on the desired geometry of the final part.

- CNC Turning: This is ideal for creating cylindrical parts like rings, shafts, seals, and rollers.

- CNC Milling: This technique is used for more complex shapes, including intricate patterns, blocks, and parts with cavities.

- Drilling and Tapping: These processes are used to create precise holes and internal threads within PTFE components.

Critical Considerations for Precision

The primary challenge in machining PTFE is not cutting the material, but controlling its physical response to the machining process. Its properties make achieving and holding tight tolerances difficult.

Managing Thermal Expansion

PTFE has a very high coefficient of thermal expansion. Even a small amount of heat generated from cutting friction will cause the material to expand, compromising dimensional accuracy. To counter this, integrated coolant systems are essential to dissipate heat at the point of contact.

The Importance of Sharp Tooling

Using extremely sharp and polished cutting tools is non-negotiable. HSS (High-Speed Steel) or carbide tools are recommended. A sharp edge produces a clean shearing action, which minimizes friction, heat buildup, and material deformation.

Optimizing Speeds and Feeds

The goal is to remove material efficiently without generating excessive heat. Machinists typically use moderate cutting speeds (around 200 to 500 surface feet per minute) and relatively high feed rates (0.002 to 0.010 inches per revolution) to prevent the tool from dwelling and imparting heat.

Applying Correct Clamping Pressure

PTFE is soft and prone to stress creep, meaning it will slowly deform under constant pressure. Fixtures and clamps must apply only the minimum pressure necessary to hold the workpiece securely. Excessive force will compress the material, leading to inaccurate dimensions once the part is released.

Understanding the Trade-offs

Machining PTFE involves balancing its ease of cutting against its challenging physical properties. Ignoring these trade-offs is a common source of failure.

The Challenge of Tight Tolerances

The combination of high thermal expansion and stress creep makes PTFE a difficult material for applications requiring extremely tight tolerances. The part's final dimensions can change significantly as it returns to ambient temperature or is removed from the fixture.

Designing for the Material

Successful PTFE parts are designed with the material's properties in mind. Instead of forcing it to hold a dimension it naturally wants to change, engineers design applications that leverage its strengths, such as its unparalleled chemical resistance and low-friction surface.

Why Choose PTFE?

Despite the machining challenges, PTFE is chosen for its remarkable combination of properties. It is virtually impervious to chemical attack, is an excellent electrical insulator, and has fantastic non-stick characteristics. This makes it indispensable for components like chemical-resistant seals, high-performance bearings, non-stick coatings, and electrical insulators.

Making the Right Choice for Your Goal

Your approach to machining PTFE should be dictated by the final application's requirements.

- If your primary focus is high-precision components: Prioritize aggressive thermal management with coolant and minimize all clamping pressure to prevent distortion.

- If your primary focus is prototypes or non-critical parts: You can leverage PTFE's easy machinability for rapid production, as minor dimensional variances may be acceptable.

- If your primary focus is chemical resistance or low friction: Design the part from the outset to capitalize on these unique strengths, allowing for more generous tolerances where possible.

Ultimately, mastering PTFE machining is about controlling the environment to work with the material's nature, not against it.

Summary Table:

| Property | Impact on Machining | Key Consideration |

|---|---|---|

| Soft & Slippery | Easy to cut | Requires sharp tools for clean shearing |

| High Thermal Expansion | Dimensions change with heat | Coolant systems are essential |

| Prone to Stress Creep | Deforms under pressure | Minimal clamping force required |

| Excellent Chemical Resistance | Ideal for harsh environments | Design to leverage this strength |

Need high-precision, chemically resistant PTFE components?

At KINTEK, we specialize in machining PTFE (Teflon) for the most demanding applications. Our expertise in managing thermal expansion and stress creep ensures your custom seals, liners, and labware meet exact specifications.

We serve the semiconductor, medical, laboratory, and industrial sectors with:

- Prototype to high-volume production

- Precision CNC milling and turning

- Custom fabrication for complex geometries

Leverage our material science knowledge to get parts that perform. Contact our engineering team today to discuss your project requirements.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments